Automatic insertion and separation lock catch

An automatic and locking technology, applied to buckles, fasteners, clothing, etc., can solve the problems of users' irritability, slow locking process, inaccurate locking and other problems, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

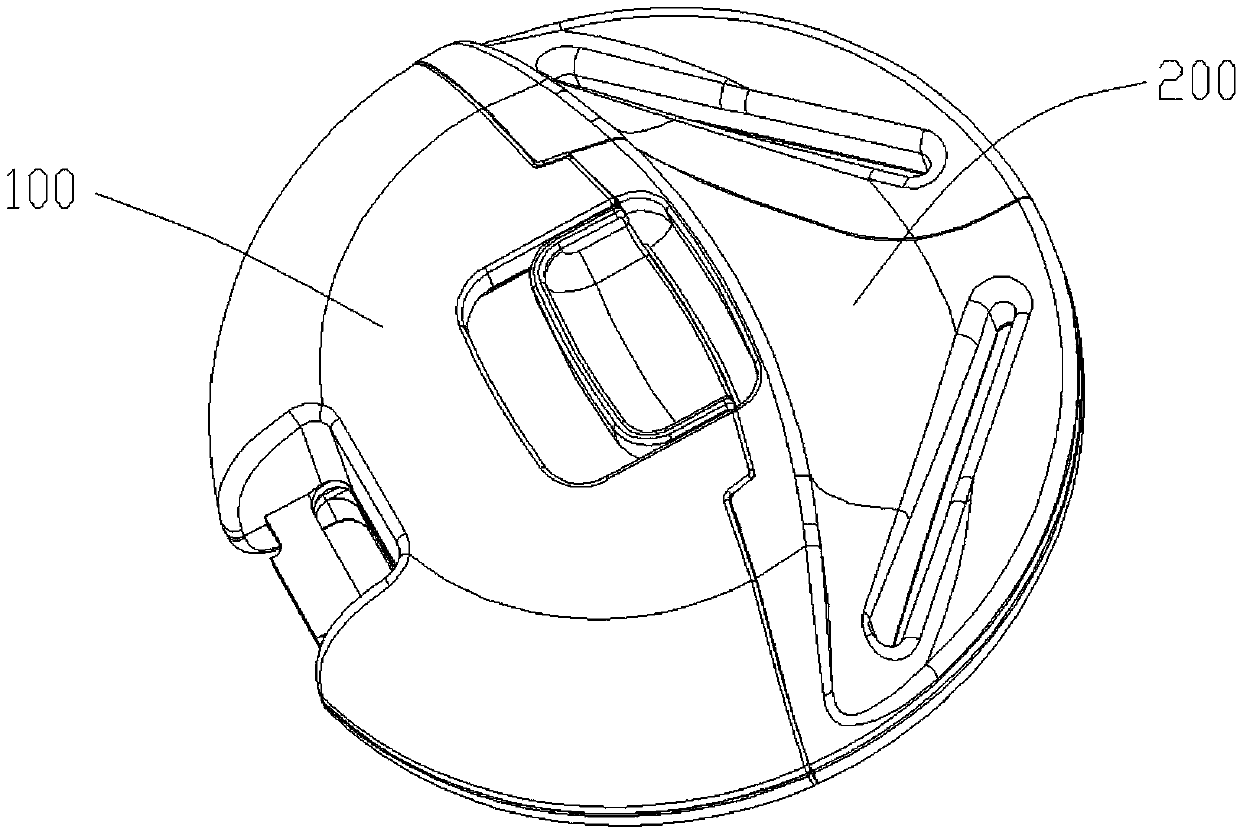

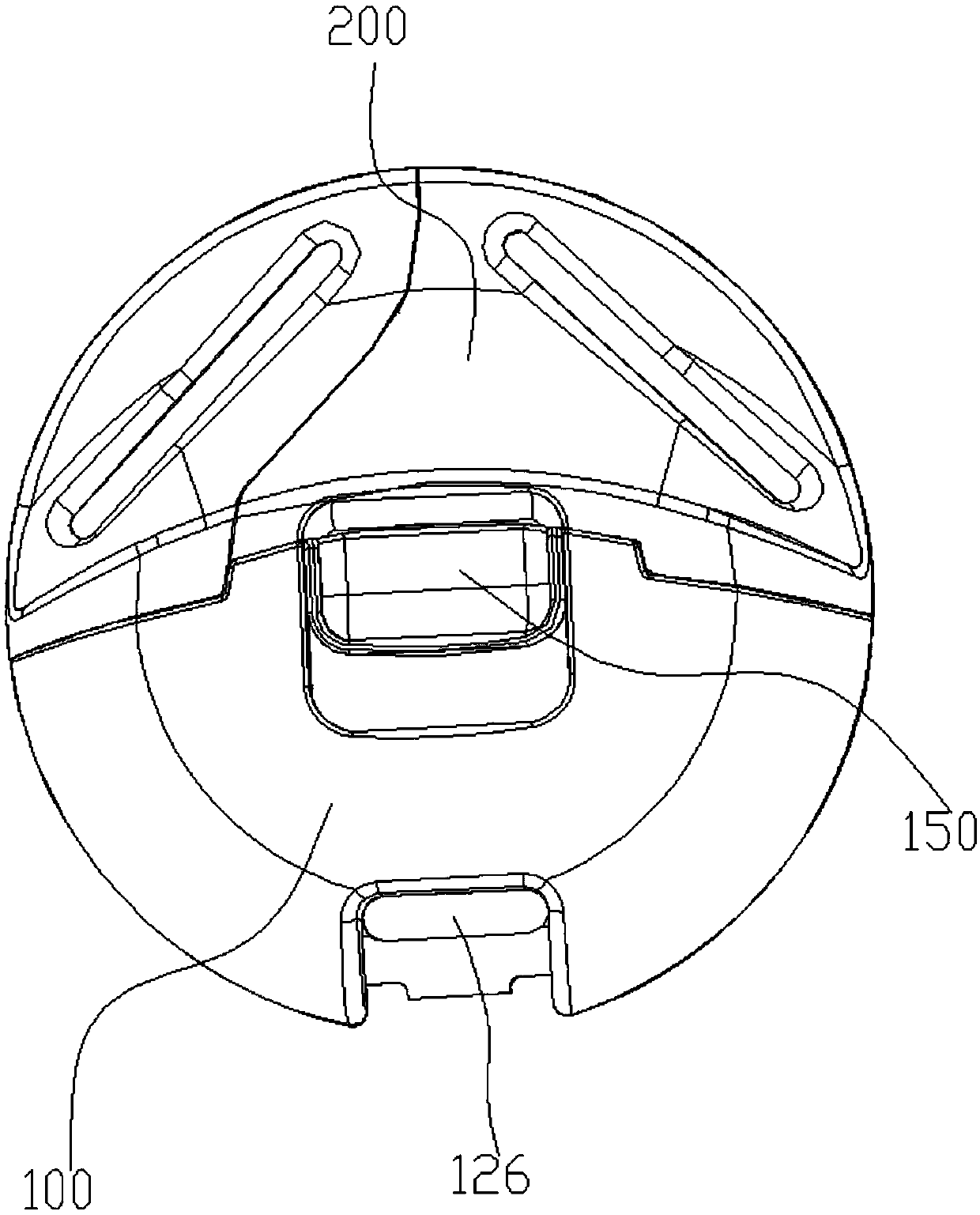

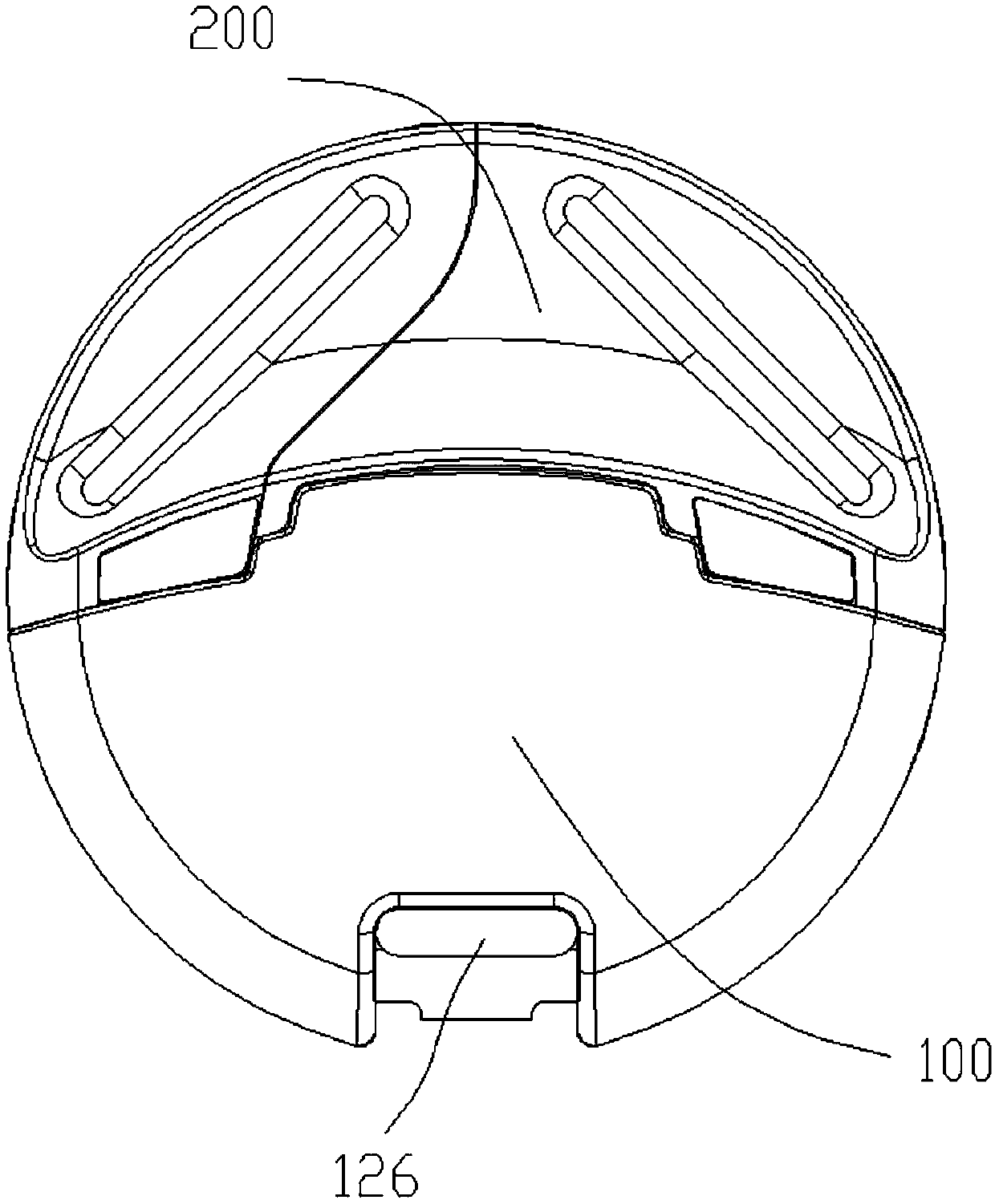

[0068] Such as figure 1 — Figure 17 As shown, in the present invention, the buckle only has three directions, that is, a connection end is arranged behind the first lock part, and the second lock part is divided into two directions of the first lock piece and the second lock piece, and the first lock piece is connected to the second lock piece. External terminals are respectively arranged behind the first locking piece and the second locking piece, and the opening and closing of the three-way lock is completed through the conversion of magnetic poles.

[0069] The three-way lock is suitable for use in various places such as bags, strollers, and baby seats that require three different directions to be locked at one point.

Embodiment 2

[0071] Different from the above-mentioned embodiments, in the present invention, the buckle only has two directions, that is, the rear of the first lock part and the rear of the second lock part, each of which is provided with an external connection end, and the opening and closing of the two-way lock buckle is completed through magnetic pole conversion. .

[0072] The two-way lock is suitable for use in the connection of various bags and two-way belts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com