Assembled steel structural outer corner hanging plate die and use method thereof

A steel structure and assembly technology, which is applied in the direction of molds, mold auxiliary parts, manufacturing tools, etc., can solve the problems of prefabrication of corner external hanging panels, etc., and achieve the effects of shortening the construction period, convenient and quick use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

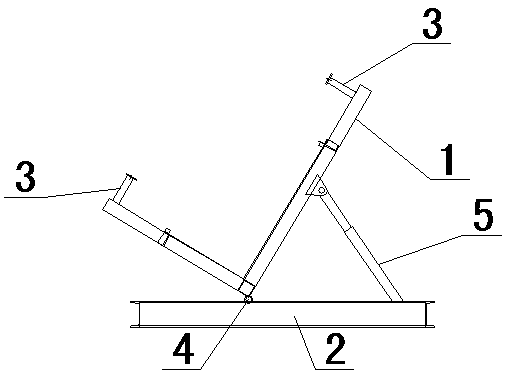

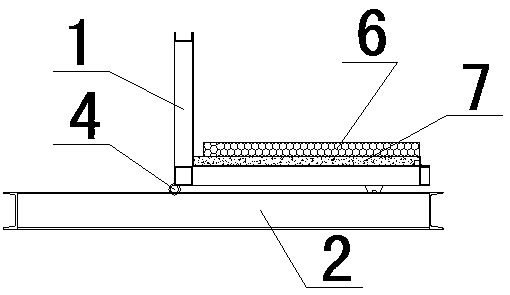

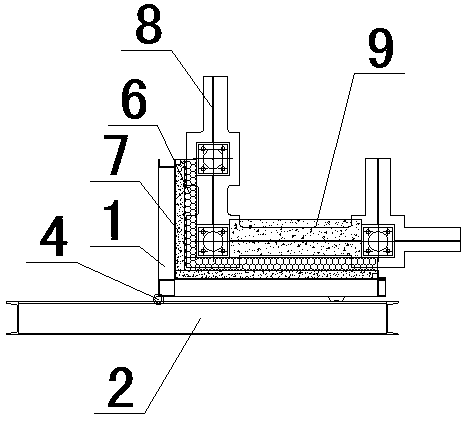

[0025] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , an assembled steel structure corner external panel mold, including a corner mold 1 and a base 2, the corner mold 1 has an L-shaped structure, and two right-angled sides of the corner mold 1 are respectively provided with clamps 3 at positions corresponding to the steel column corbels , the right-angle bottom end of the corner mold 1 is installed on the base 2 through the linkage shaft 4, one right-angle side of the corner mold 1 is connected with the base 2 through the hydraulic telescopic rod 5, and the corner mold 1 is completed on the base 2 through the expansion and contraction of the hydraulic telescopic rod 5 90° flip.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com