A kind of embossed enamel plate and its processing method

A processing method and technology for enamel plates, which are applied in the direction of processing models, processes for producing decorative surface effects, decorative arts, etc., and can solve the problems of single color or shape, poor roundness and smoothness of the surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

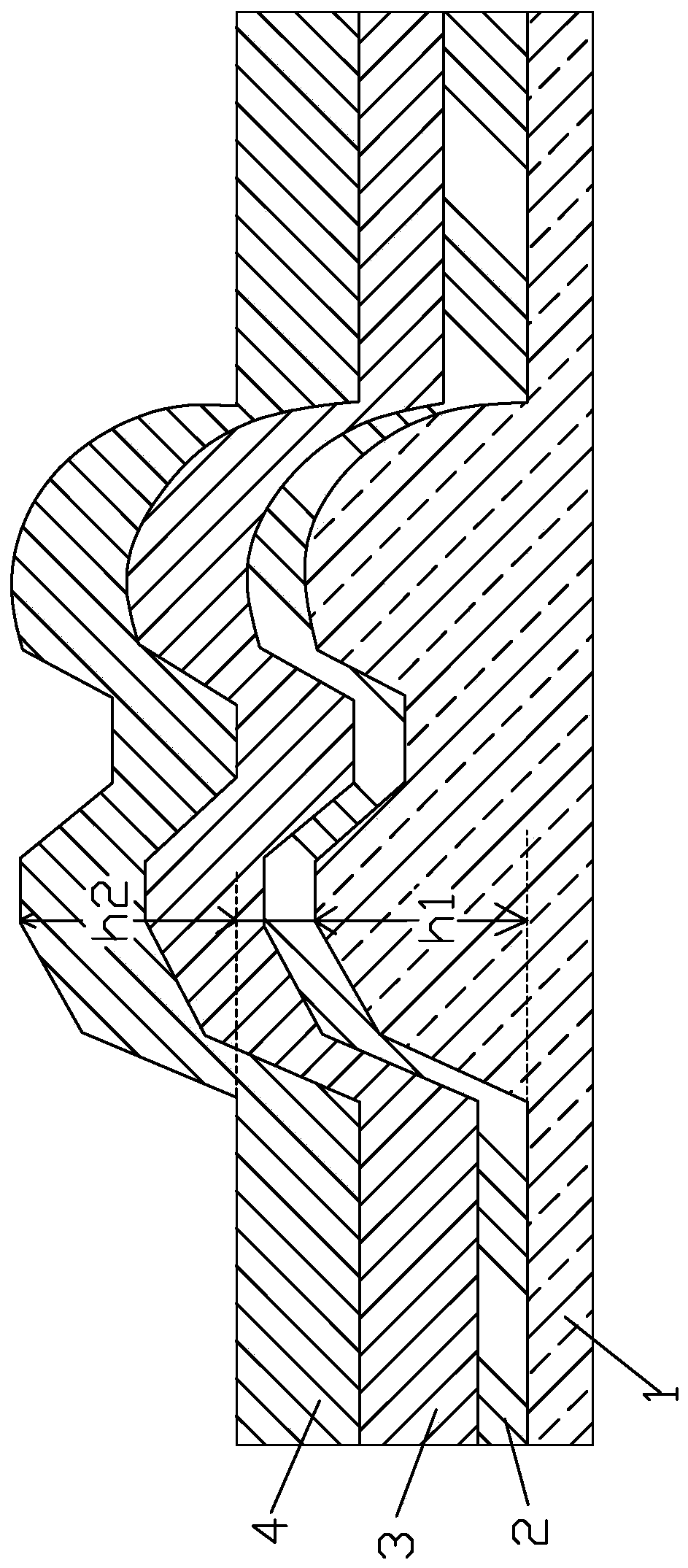

Image

Examples

Embodiment 1

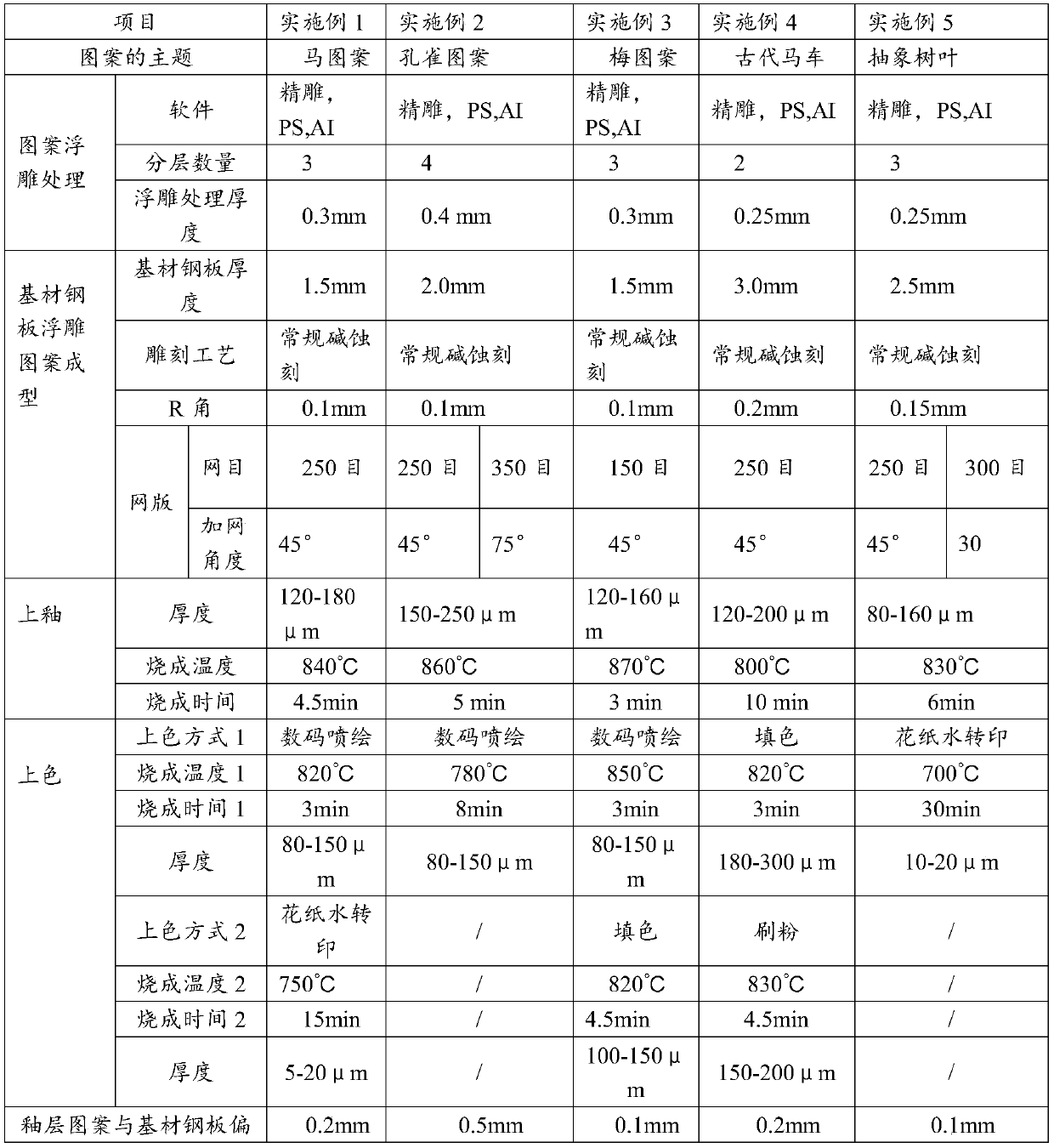

[0032] Embodiment 1 discloses an embossed enamel plate and a processing method thereof, using the method to prepare an enamel plate with a relief effect of a horse pattern.

[0033] A method for processing a relief enamel plate, comprising the following steps:

[0034] (1) Pattern embossment processing: the elements in the pattern are layered in the X direction, Y direction and Z direction according to the three-dimensional position with the relief making software, and are divided into 3 layers;

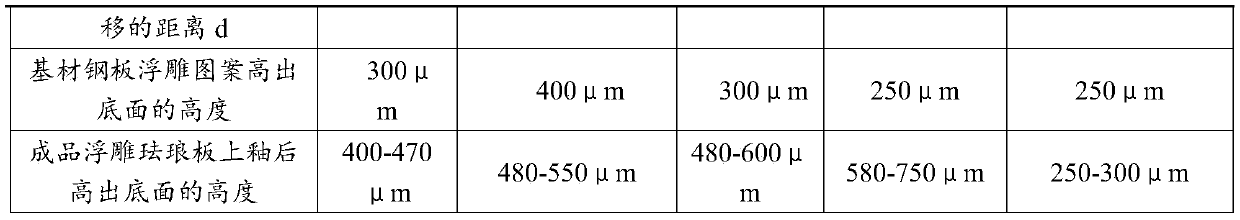

[0035] (2) Forming of the embossed pattern of the substrate steel plate: the layered pattern is made into a screen, and the substrate steel plate is processed and formed with a three-dimensional pattern through the screen; the height of the embossed pattern of the substrate steel plate above the bottom surface is 300 μm;

[0036] The R angle range of the contour knife edge edge for engraving the substrate steel plate is 0.1mm;

[0037] The mesh of the screen version is 250 mesh, and...

Embodiment 2

[0048] The main difference between this embodiment and Example 1 lies in the coloring method and the specific process parameters used in each production step, etc., the specific values and coloring method differences are shown in Table 1; the main characteristics of the embossed enamel plate made in this embodiment The evaluation indicators are detailed in Table 1.

Embodiment 3

[0050] The main difference between this embodiment and Example 1 lies in the coloring method and the specific process parameters used in each production step, etc., the specific values and coloring method differences are shown in Table 1; the main characteristics of the embossed enamel plate made in this embodiment The evaluation indicators are detailed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com