Automobile door adjusting mounting device and working method thereof

An installation device and a technology for automobile doors, which are applied to motor vehicles, metal processing, manufacturing tools, etc., can solve problems such as the inability to realize rapid and automatic measurement of door gaps and surface differences, so as to ensure the uniformity of the overall gap and surface difference and realize automatic measurement. The effect of adapting to the adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

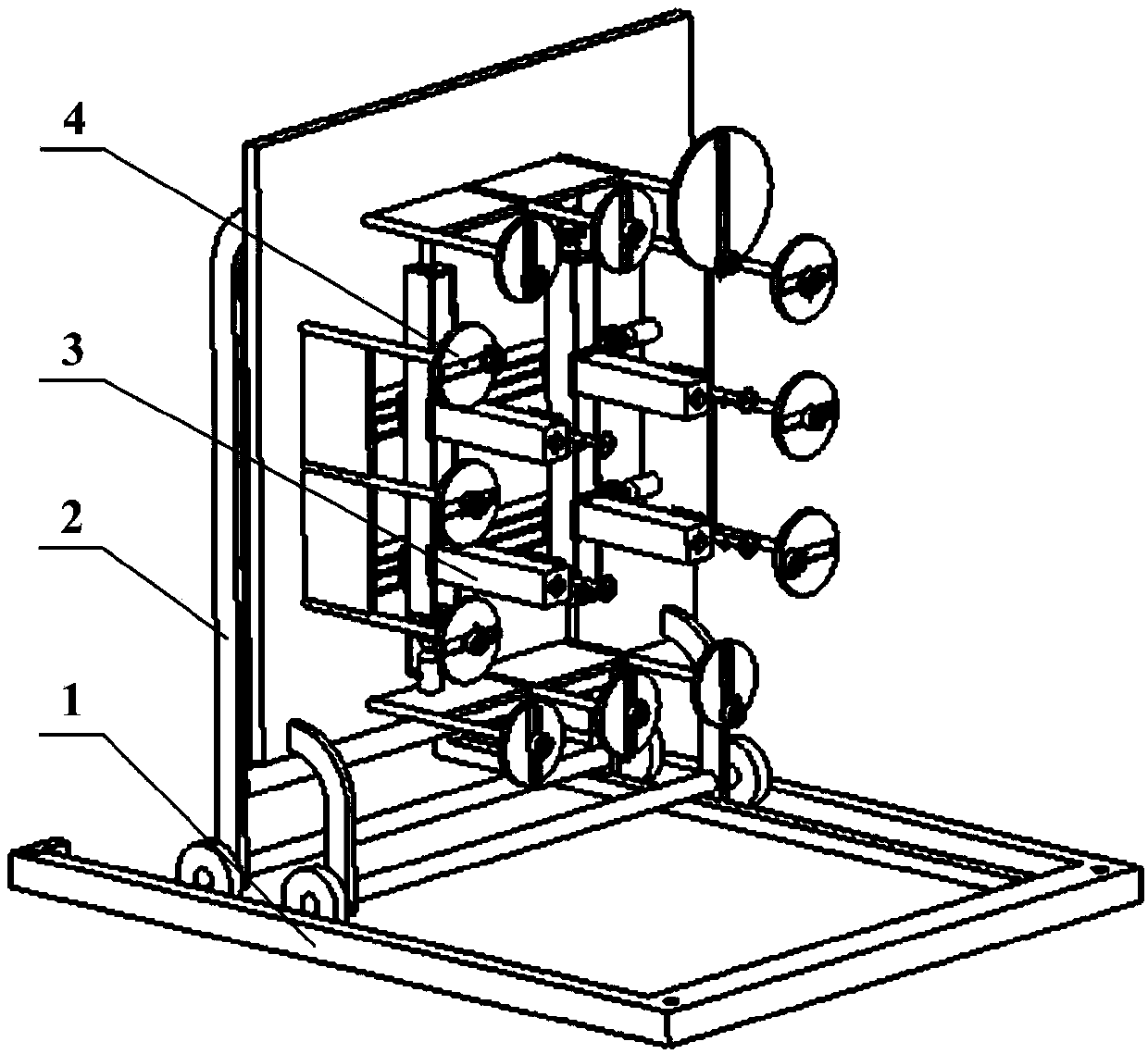

[0050] An automobile door adjustment and installation device comprises a bottom plate guide rail 1, a running mechanism 2, a vehicle door adjustment mechanism 3, and a measuring mechanism 4.

[0051] A running mechanism 2 is arranged on the bottom plate guide rail 1 , and the bottom plate guide rail 1 is used to support the walking movement of the running gear 2 .

[0052] The running mechanism 2 is provided with a door adjusting mechanism 3 and a measuring mechanism 4, and the running mechanism 2 is used to drive the walking of the door adjusting mechanism and the measuring mechanism; when the door is installed, the initial position of the door is positioned and the overall device is removed after installation.

[0053] The car door adjustment mechanism 3 comprises a transverse movement mechanism, the transverse movement mechanism is provided with a longitudinal movement mechanism, and the longitudinal movement mechanism is provided with a vertical movement mechanism, and the ...

Embodiment 2

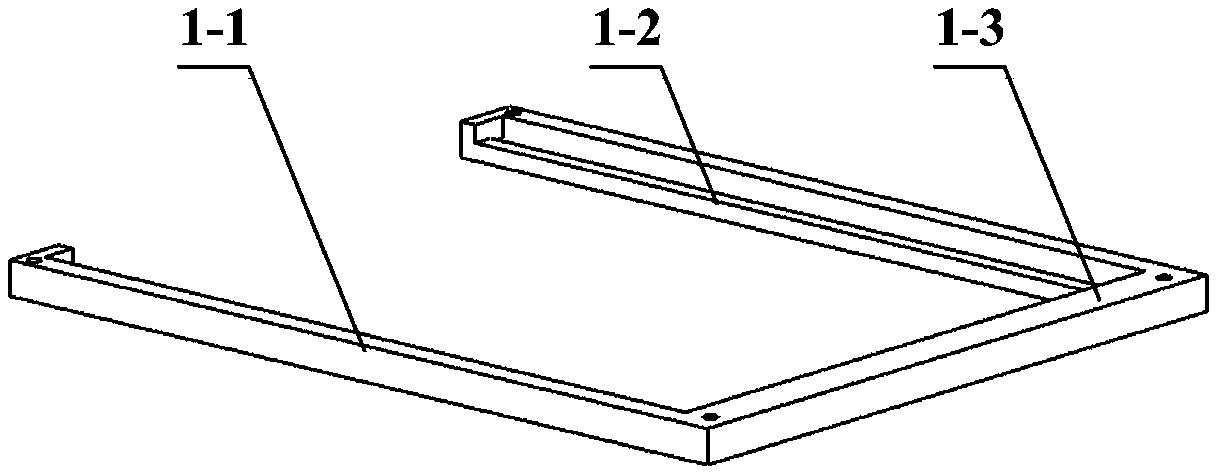

[0056] An automobile door adjustment installation device, its structure is as described in Embodiment 1, the difference is that the bottom plate guide rail 1 includes two parallel guide rail beams, such as figure 2 In the guide rail beam A 1-1 and guide rail beam B 1-2 shown in , groove guide rails are provided on the upper surface of the guide rail beams, and end beams 1-3 are connected between the two guide rail beams. The guide rail beam and the end beam are welded into a frame structure with one end open. The bottom plate guide rail is installed next to the body assembly line. The position of the end beam ensures that the door driven by the traveling mechanism is in a proper initial position before installation.

Embodiment 3

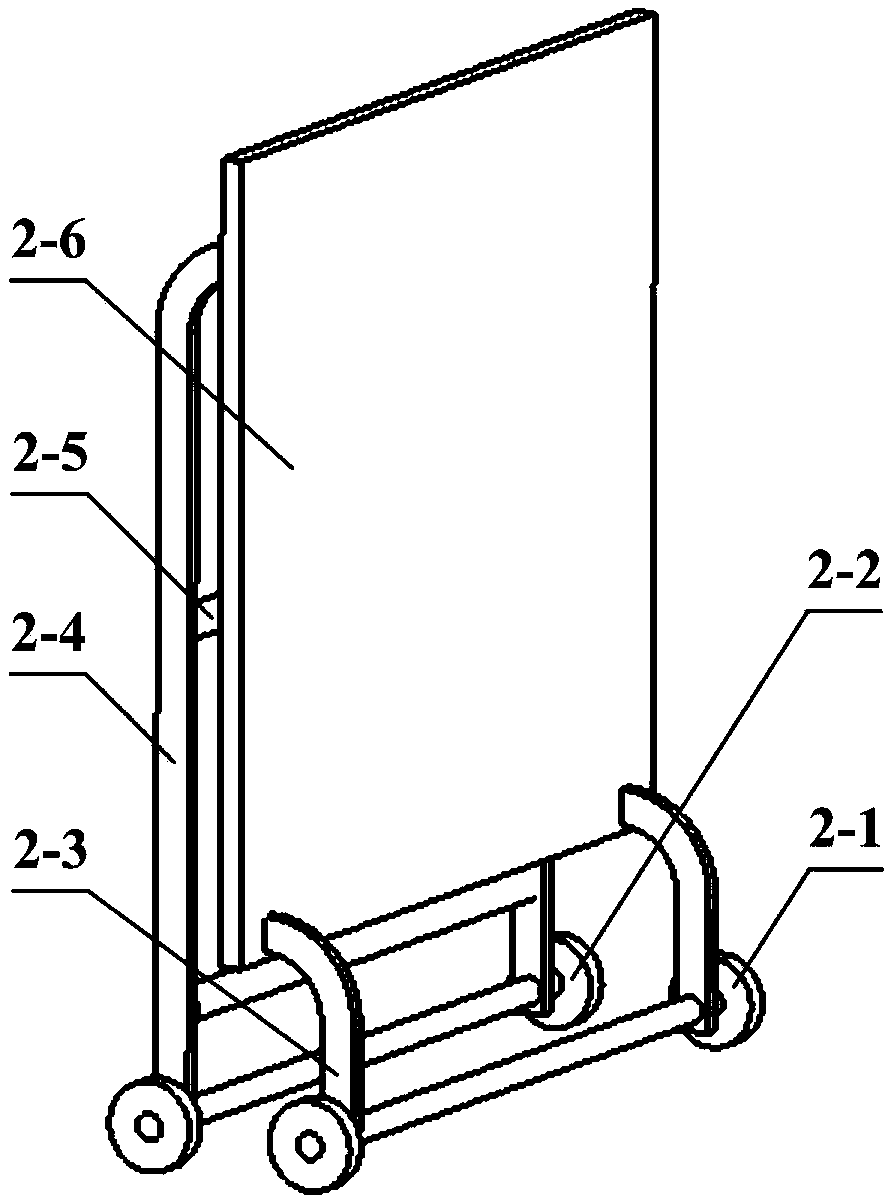

[0058] An automobile door adjusting installation device, its structure is as described in embodiment 2, the difference is that the traveling mechanism includes an installation base plate 2-6, and the bottom of the installation base plate is connected with a wheel set by a connecting arm, and the wheel set is located on the base plate guide rail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com