Assembly type light-weight partition wall plate

A light-weight partition board and assembled technology, which is applied in the direction of building components, buildings, building structures, etc., can solve problems that affect the assembly process and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

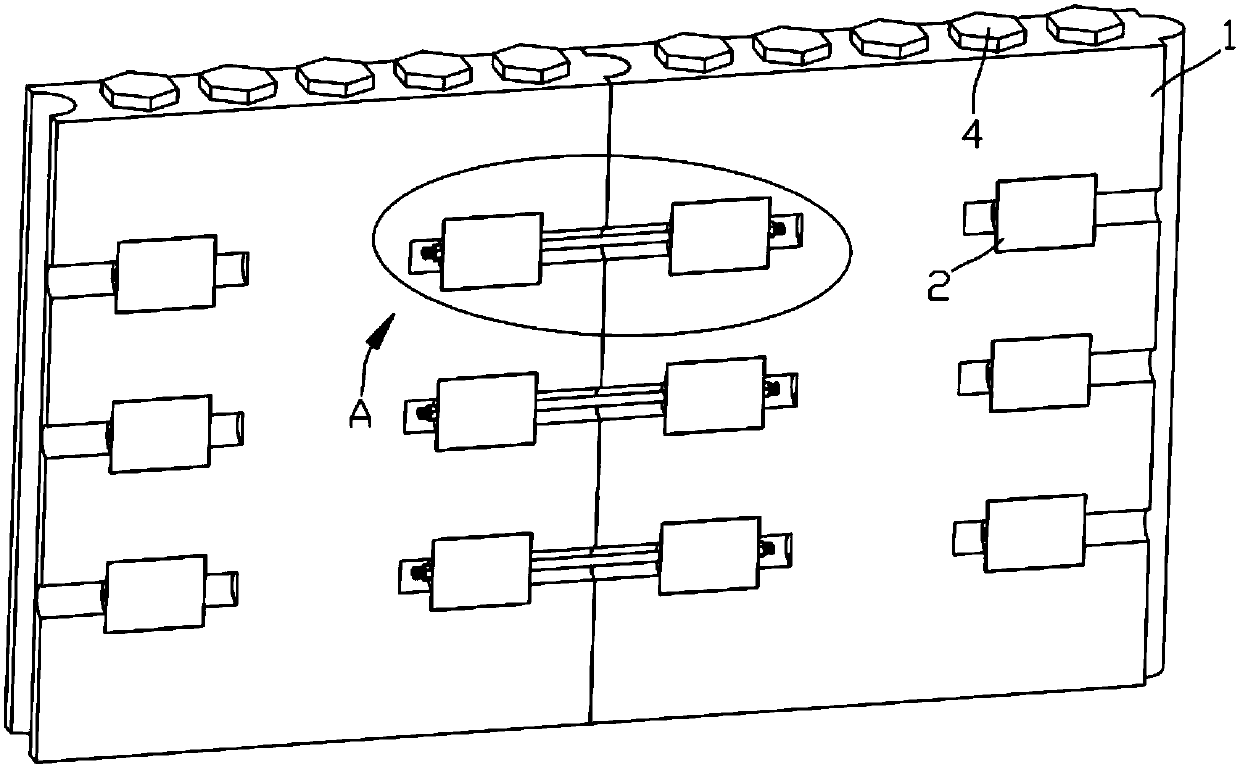

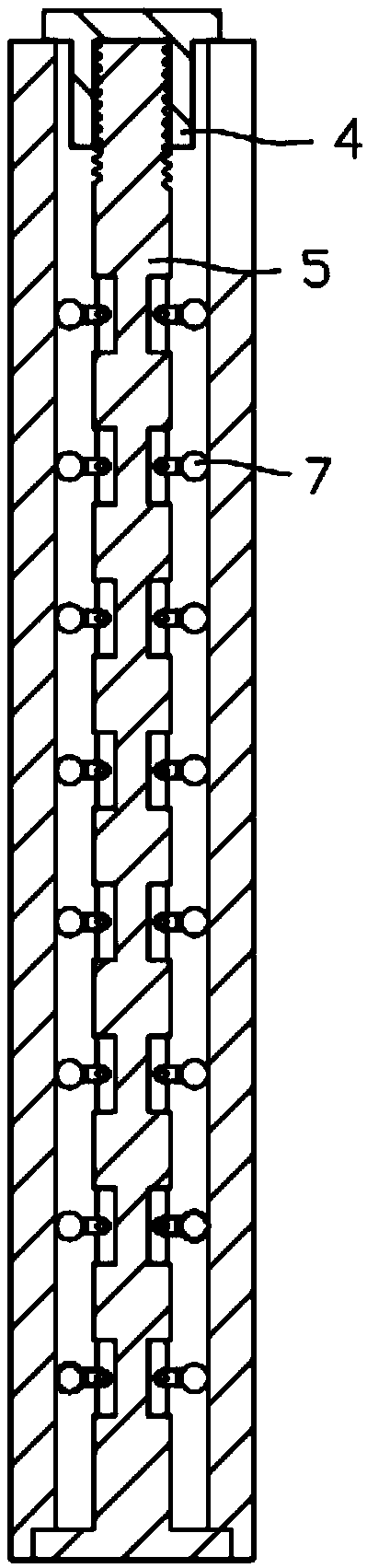

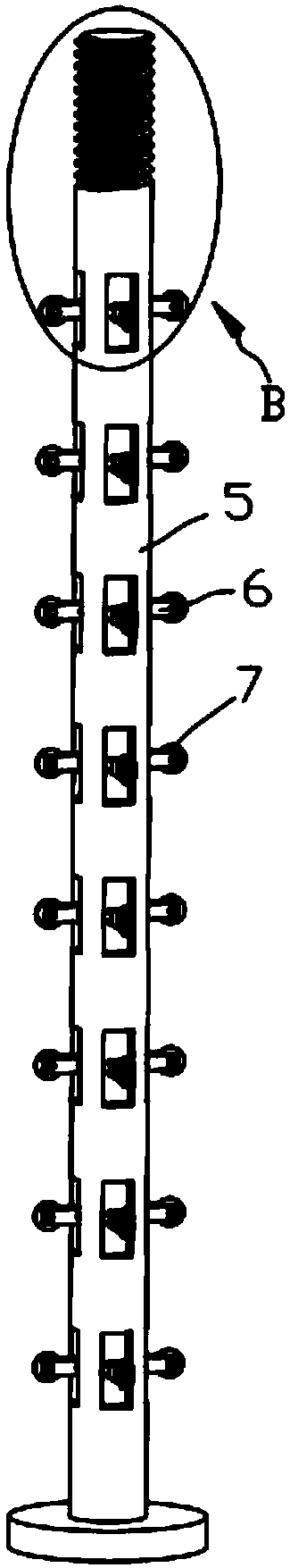

[0023] see Figure 1 to Figure 6 , the present invention provides a technical solution:

[0024] An assembled lightweight partition wall panel, including a wall panel 1, a pull plate 2, a pull rod 3, a sleeve 4, a push rod 5, a bracket 6 and a roller 7, wherein:

[0025] Two wallboards 1 fit each other, wherein the wallboard 1 is provided with a number of through holes 11, and at least four drawboards 2 are symmetrically installed on the wallboard 1, and the two sides of the wallboard 1 are provided with the same number of drawboards. Plate 2, wherein the installation form of the tie plate 2 is a countersunk installation and is fixedly connected with the wall panel 1. At least two tie rods 3 penetrate through the tie plate 2 on the two wall panels 1, and the two ends of the tie rods 3 respectively penetrate Pass the pull plates 2 on the two wall panels 1 and fix them with bolts respectively, and the pull plates 2 on both sides of the wall panels 1 are fixed in this way, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com