Assembly type upright pillar module for building

A building column and prefabricated technology, used in buildings, building components, building insulation materials, etc., can solve the problem that the sealing effect of the annular gap between the bottom of the column and the building foundation is not very good, and the operation of the column module and the building foundation is cumbersome. , the problem of the connection between the column module and the building foundation is troublesome, so as to achieve the effect of simple structure, good flatness and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below will combine specific embodiment and appended Figure 1-6 , clearly and completely describe the technical solutions in the embodiments of the present invention, obviously, the described embodiments are only some preferred embodiments of the present invention, not all the embodiments. Those skilled in the art can make similar modifications without departing from the connotation of the present invention, so the present invention is not limited by the specific embodiments disclosed below.

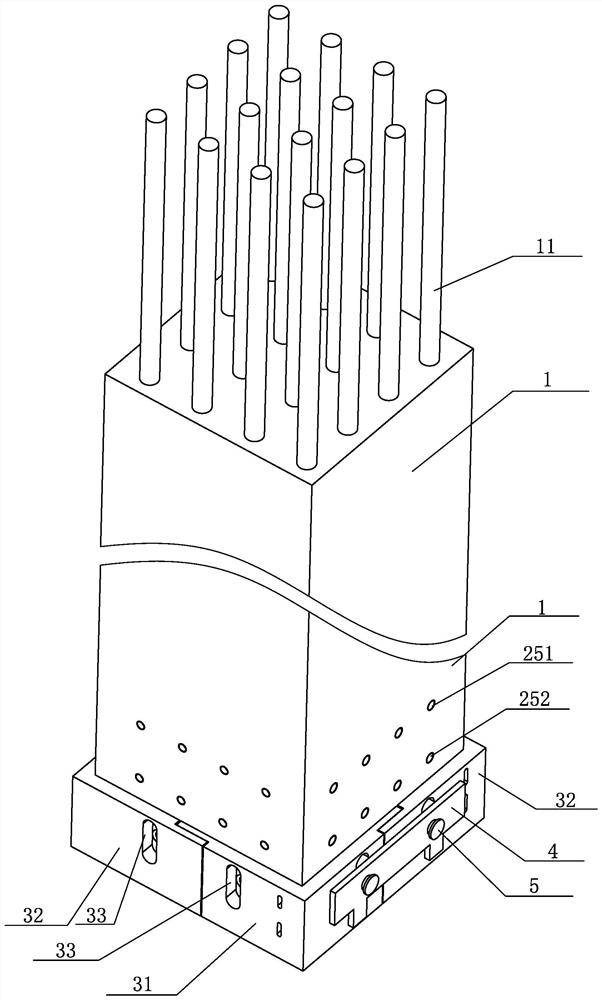

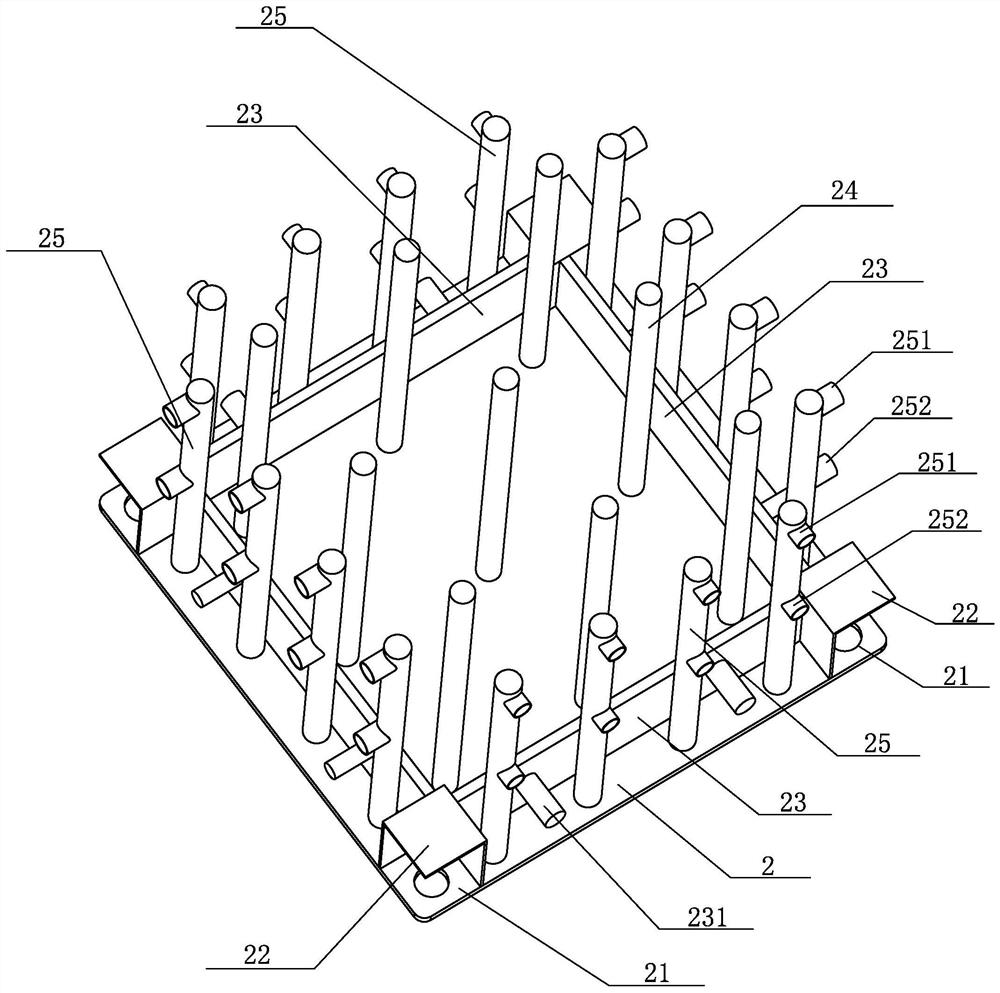

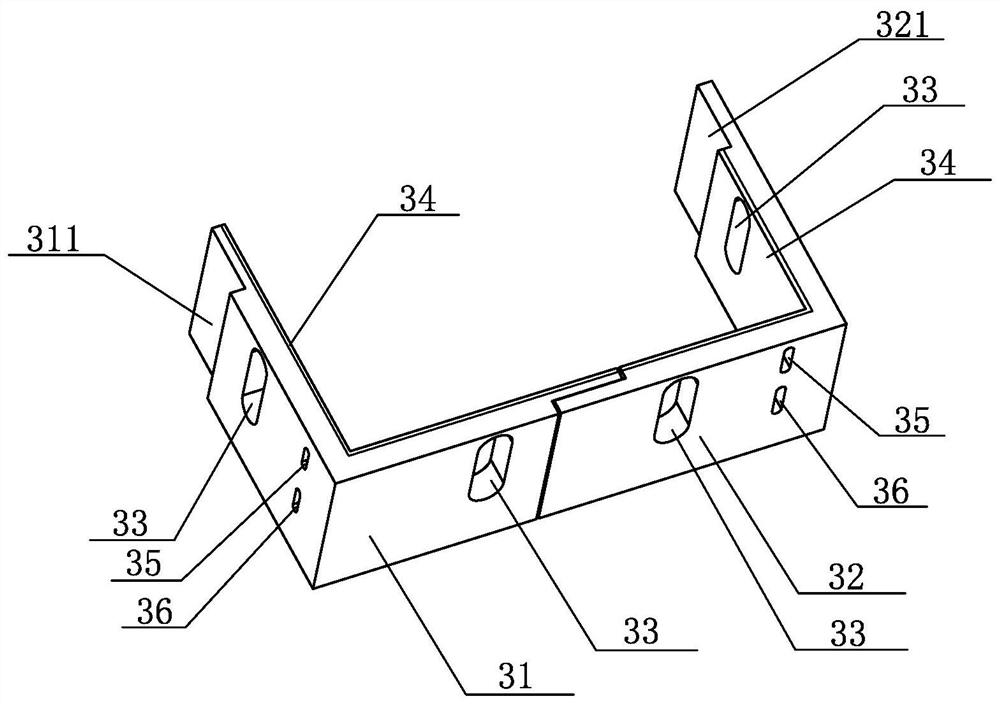

[0020] The invention provides an assembled building column module (such as figure 1 shown), comprising a square column 1, a docking base and a pouring auxiliary device, the square column 1 includes a steel cage skeleton and concrete, and the pouring of the steel cage skeleton and concrete is a prior art in the art, so here, for The prefabricated manufacturing process of the square column 1 will not be described in detail any more. On the upper part of the square column 1, there a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com