Flat gate valve

A flat gate valve and valve stem technology, which is applied to sliding valves, valve devices, engine components, etc., can solve the problems of inaccurate judgment of the operating position of the gate, erosion of the gate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

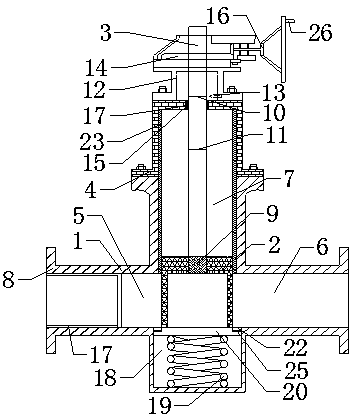

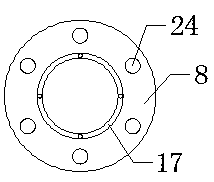

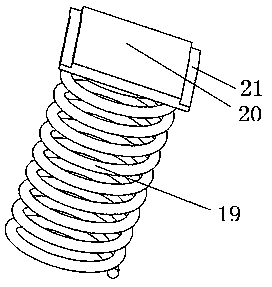

[0028] As a most basic embodiment of the present invention, this embodiment discloses a flat gate valve, such as figure 1 As shown, it includes a valve body 1, a gate plate 2, a valve stem 3 and a bonnet 4. The valve body 1 is provided with an inflow channel 5, an outflow channel 6 and an upper channel 7. The end of the inflow channel 5 and the outflow channel 6 ends are provided with a flange 8, the upper end of the valve body 1 is connected to the valve cover 4, the valve stem 3 penetrates the valve cover 4 and enters the interior of the valve body 1, and the valve stem 3 passes through the connecting block 9 and the gate plate 2 connected, the valve stem 3 is provided with an upper limit indicating line 10 and a lower limit indicating line 11, the valve cover 4 is connected with a bracket 12, and the bracket 12 is provided with a pointer 13, the pointer 13, the upper limit indicating line 10 Work together with the lower limit indicator line 11 to indicate the position of th...

Embodiment 2

[0031] As a preferred embodiment of the present invention, this embodiment discloses a flat gate valve, such as figure 1As shown, it includes a valve body 1, a gate plate 2, a valve stem 3 and a bonnet 4. The valve body 1 is provided with an inflow channel 5, an outflow channel 6 and an upper channel 7. The end of the inflow channel 5 and the outflow channel 6 ends are provided with a flange 8, the upper end of the valve body 1 is connected to the valve cover 4, the valve stem 3 penetrates the valve cover 4 and enters the interior of the valve body 1, and the valve stem 3 passes through the connecting block 9 and the gate plate 2 connected, the valve stem 3 is provided with an upper limit indicating line 10 and a lower limit indicating line 11, the valve cover 4 is connected with a bracket 12, and the bracket 12 is provided with a pointer 13, the pointer 13, the upper limit indicating line 10 Work together with the lower limit indicator line 11 to indicate the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com