Test strip drying device

A technology of drying device and test strip, applied in drying chamber/container, drying solid material, local stirring dryer, etc., can solve the problems of slow drying speed and poor effect of dryer, achieve fast drying effect and ensure drying effect, the effect of preventing the entry of moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

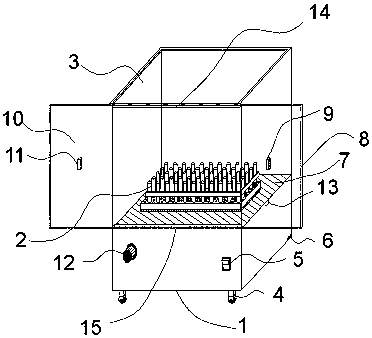

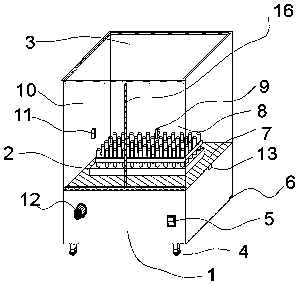

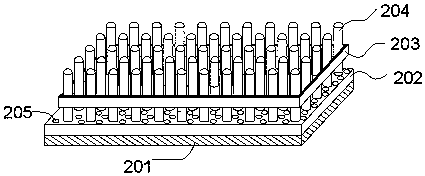

[0031] Refer to attached Figure 1-4 As shown, a test strip drying device includes a base 1, a test tube rack 2 and a glass cabinet 3, a drier is provided in the base 1 for drying, and a test tube rack 2 is fixedly connected to the panel 7 on the surface of the base 1, not only It can be used to place test paper, and can also transport moisture. The test tube rack 2 includes a sealing layer 201 and a gas-permeable layer 202. The test tube rack 2 is provided with a plurality of test tubes 204. The bottom of the test tubes 204 passes through the sealing layer 201, the gas-permeable layer 202 and the panel 7 Connected with the base 1, the part of the test tube 204 exposed to the air-permeable layer 202 is provided with a vent hole 206, and a guardrail 203 is fixed around the test tube rack 2, so that the test paper can be placed better and the test paper can be layered. The upper end of the base 1 and the glass cabinet 3 Fixed connection.

[0032] The air-permeable layer 202 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com