A cooling device for a transformer

A heat dissipation device and transformer technology, which is applied in the direction of transformer/inductor cooling, transformer/inductor casing, transformer/inductor parts, etc., which can solve the problems of poor transformer oil flow, poor heat dissipation effect, and increased transportation costs. , to achieve the effect of increasing heat dissipation, good reflective effect, and fast heat transfer and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

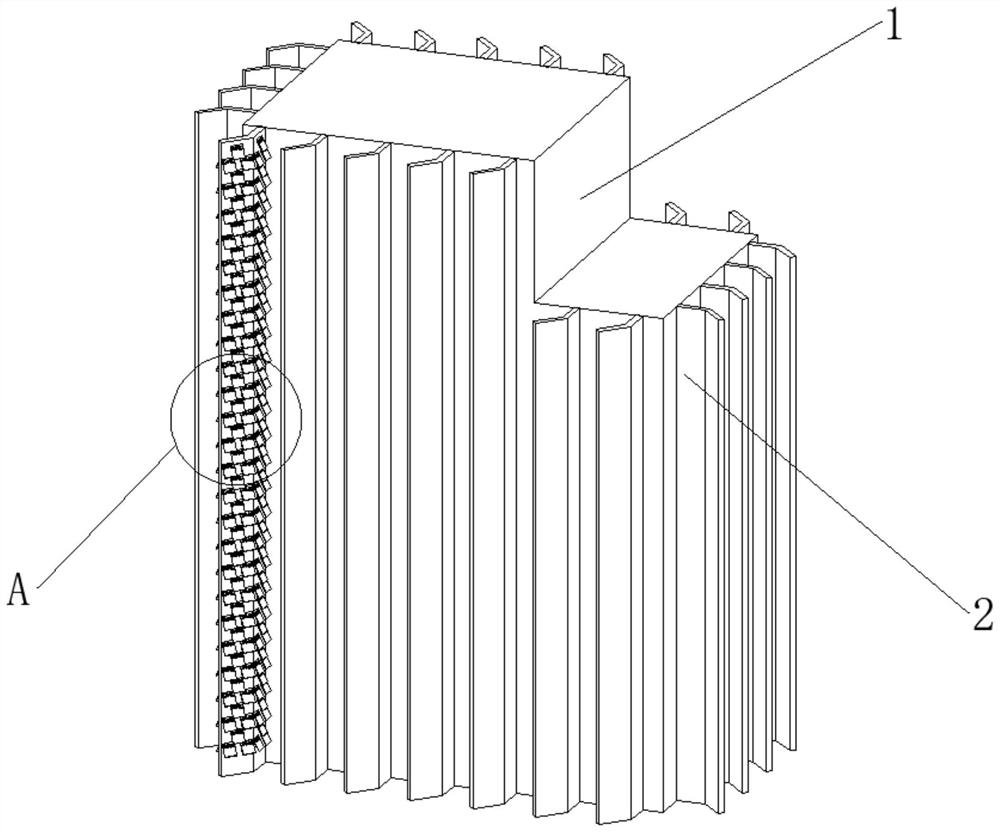

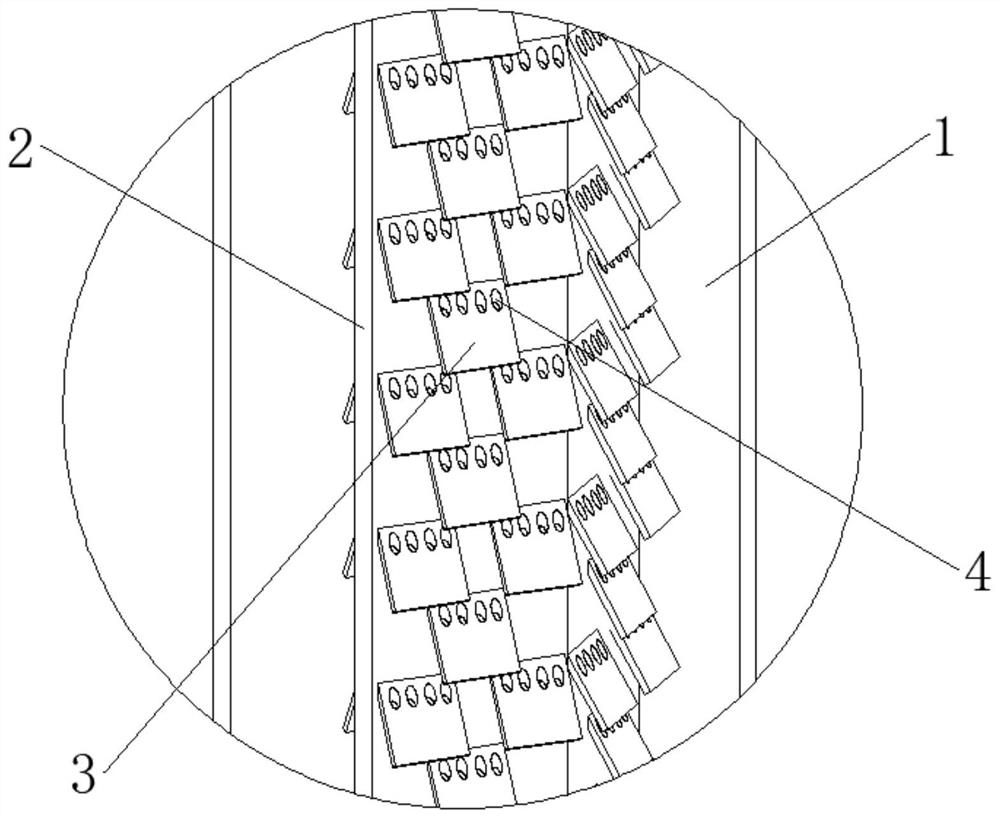

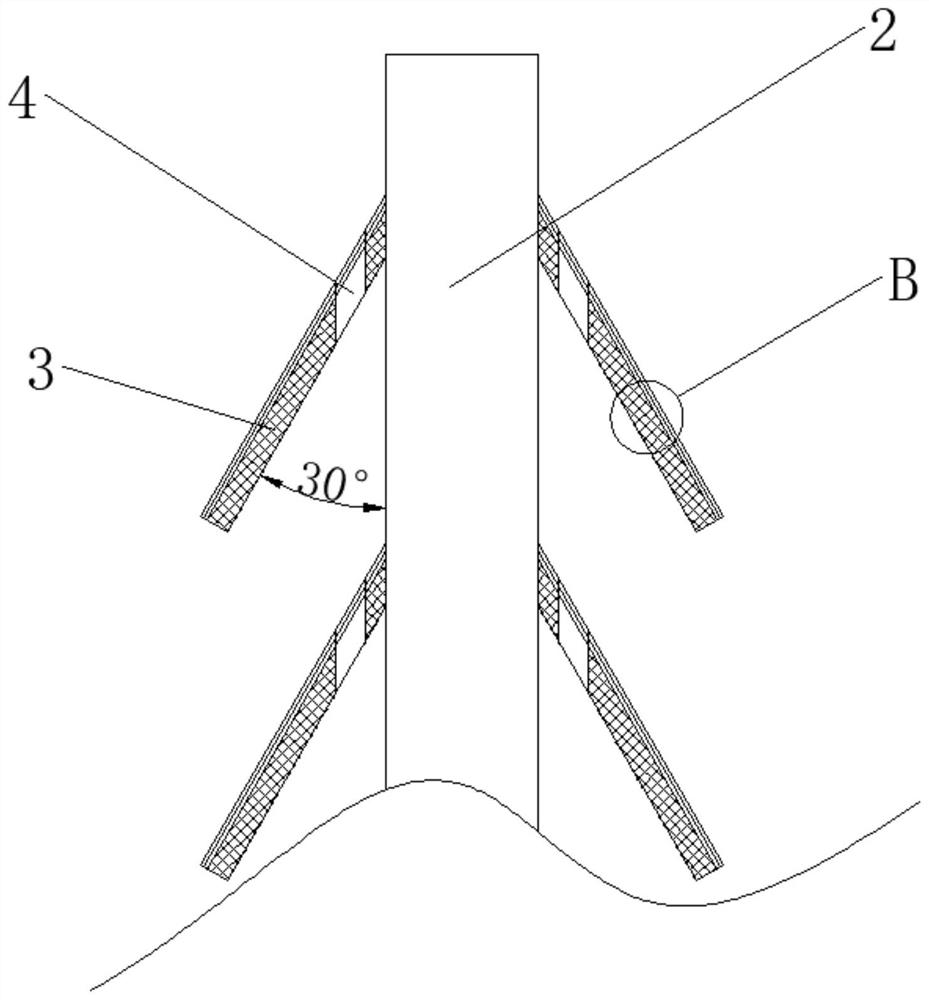

[0045] see figure 1 , a transformer chip heat dissipation device, including a transformer body 1, the transformer body 1 is an oil-immersed three-phase transformer, has a high degree of common-mode interference suppression, and the voltage tap is easy to switch, the transformer body 1 includes an iron core, a winding, an oil tank, Oil conservator, insulating bushing, tap changer, gas relay, multiple evenly distributed vertical main heat sinks 2 are welded on the side wall of the transformer body 1, and multiple heat dissipation scale bodies 3 are welded on the vertical main heat sink 2 The main body 3 of the heat dissipation scales is provided with a plurality of evenly distributed flushing diversion holes 4, and the flushing diversion holes 4 are located at one end close to the vertical main heat sink 2. The maximum height of the transformer body 1 is 1750mm, which is easy to increase the height of the heat dissipation point , the oil flow drop is large, and the heat dissipat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com