Specific durable bevel wheel

A durable, helical gear technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, components with teeth, etc., can solve the problems of single connection structure, wear of gear structure, poor connection stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

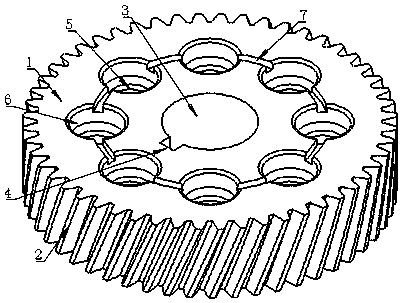

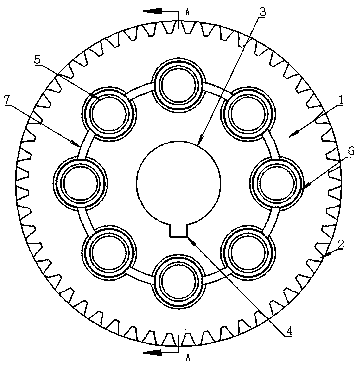

[0015] Such as Figure 1 to Figure 4 As shown in the figure, a special durable helical gear adopts a large-sized main body support column, and the helical gears evenly distributed around the circumference are arranged on the outer cylindrical surface to fit and connect the helical teeth, so that it can be combined with other helical gear structures Used together with the connection, the structure is initially assembled and connected through the central connection hole during assembly, and then the reinforced and stable connection grooves arranged symmetrically at both ends make it more firmly connected with the assembly structure, and the firmness of the assembly connection is even stronger. Reliable, better durability, and longer service life after assembly. This structure also provides lubricating and sealing connection grooves on the lower and back sides. The lubrication makes the gear structure more stable during use, and the safety is more reliable, the service life of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com