Grain intermittent sample collecting and separating device and method

An intermittent, grain technology, applied in sampling devices, sampling, measuring devices, etc., can solve problems such as paddy field pollution and excessive heavy metal content in grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

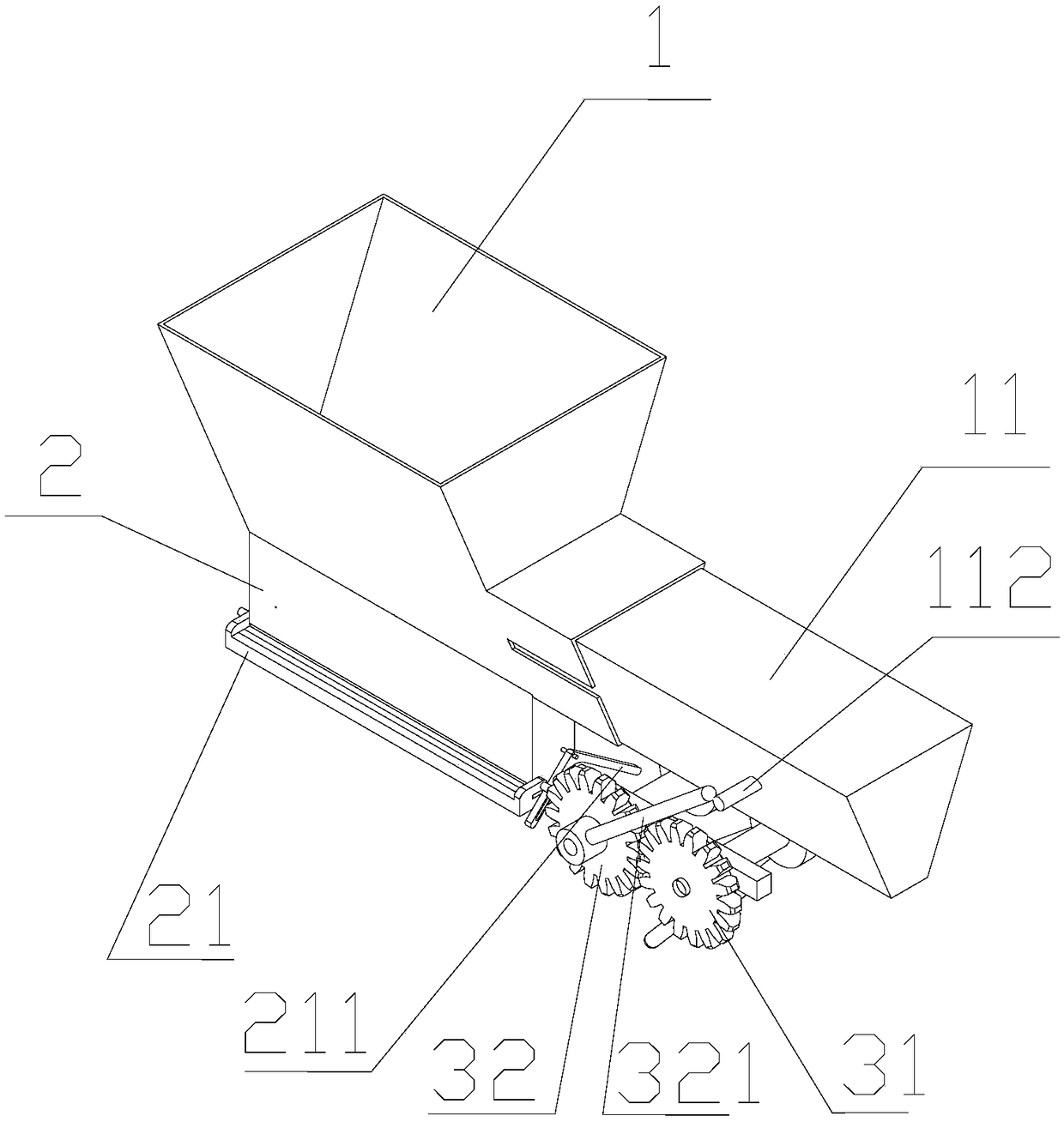

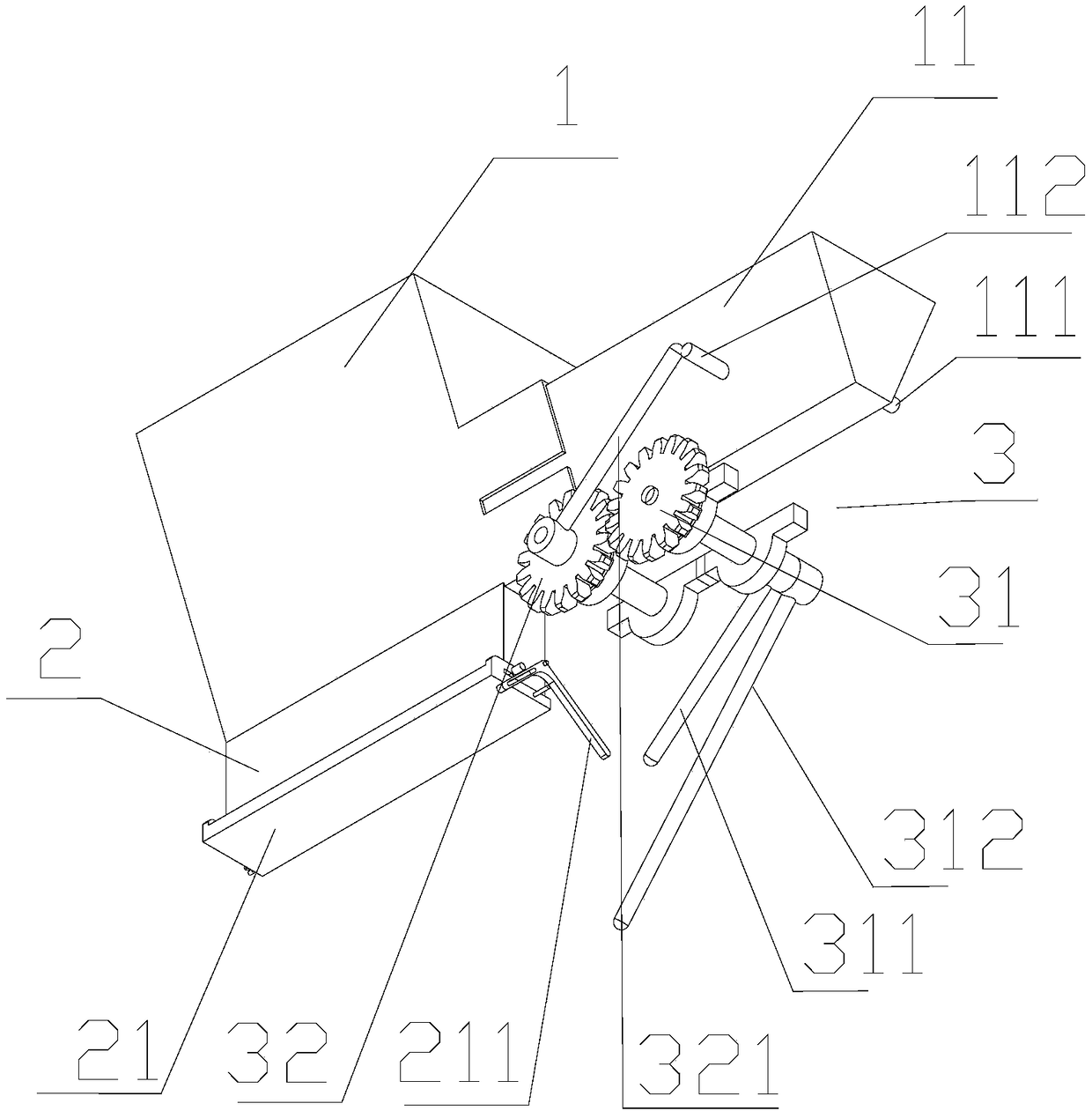

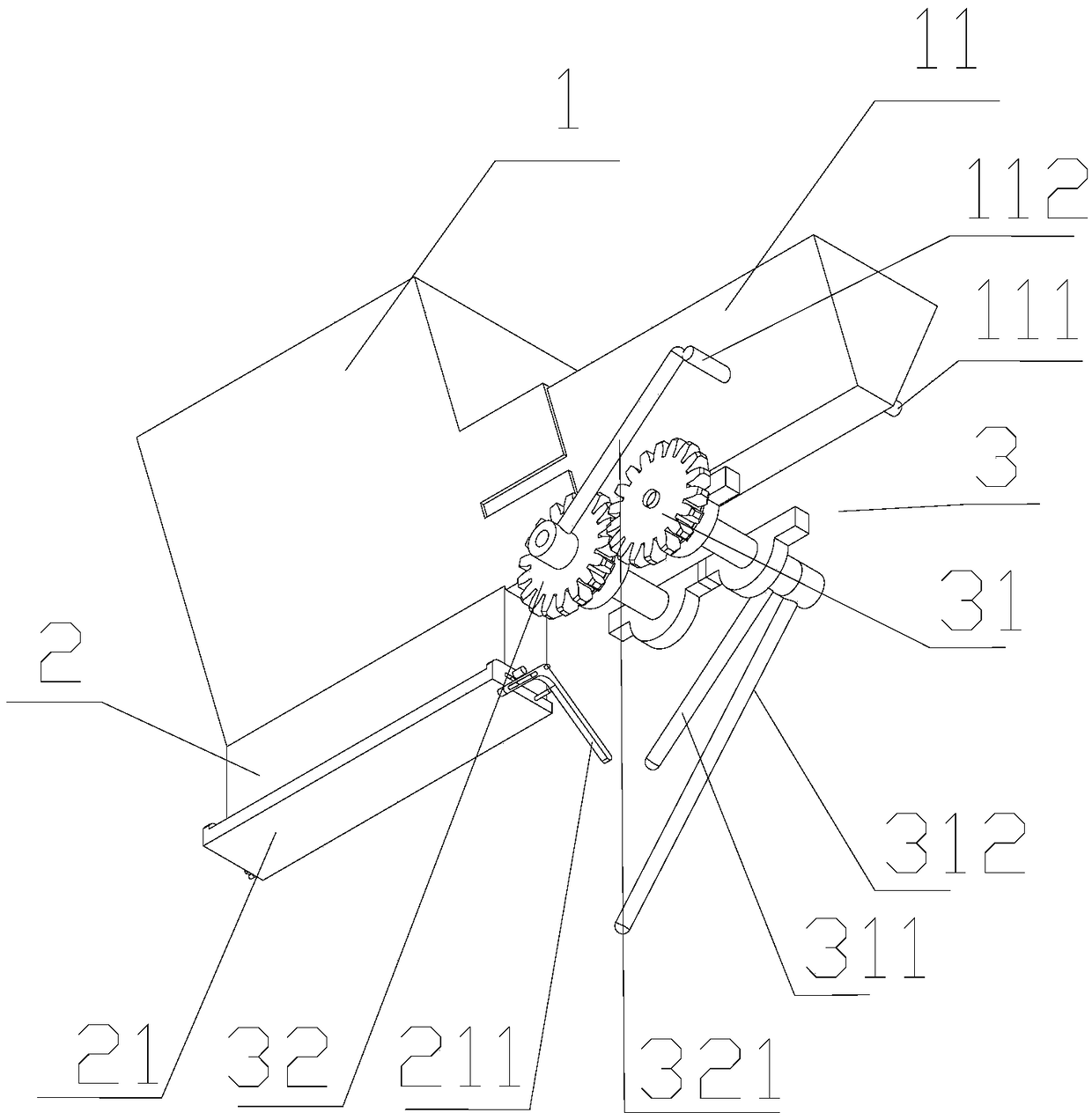

[0017] like Figure 1-Figure 5 As shown, an embodiment of a grain intermittent sampling and sampling device of the present invention includes a reclaimer 5, a retrieving bin 51 that penetrates up and down is arranged on the reclaimer 5, and the outer periphery of the reclaimer 5 is fixedly connected to the reclaimer. Gear 52, driven by power, the reclaimer 52 can rotate with the reclaimer 5 . The bottom of the reclaimer 5 is provided with a retrieving base plate 4, and a retrieving opening 41 is arranged on the retrieving base plate 4. The device 5 is rotated to a certain position, and the feed bin 51 is aligned with the feed opening 41, so that the grain enters the receiving box 1. The bottom of the material receiving box 1 is provided with a sample detector 2, and is directly connected with the sample detector 2, and the bottom of the material receiving box 1 is provided with a leveling piston 11, and under the promotion of the leveling piston 11, the Grain spread out. Bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com