A stranding device for composite cable production and its use method

A composite cable and stranded wire technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as inability to collect cables and achieve the effect of high stranded wire efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

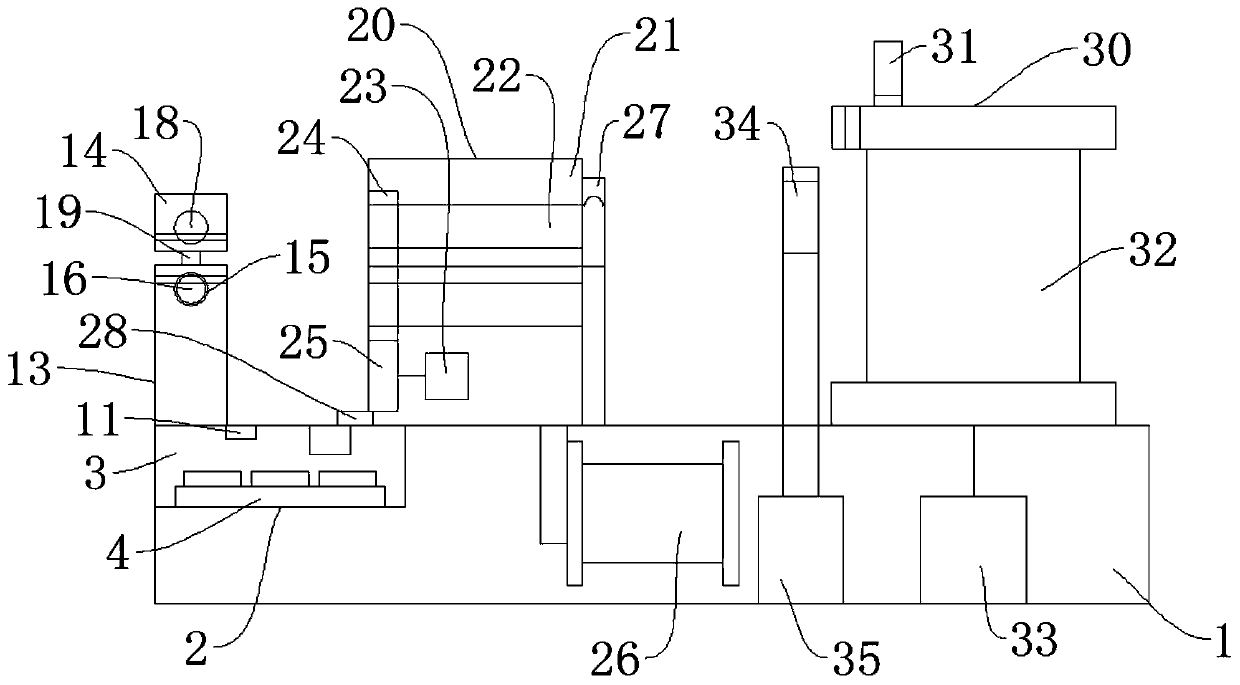

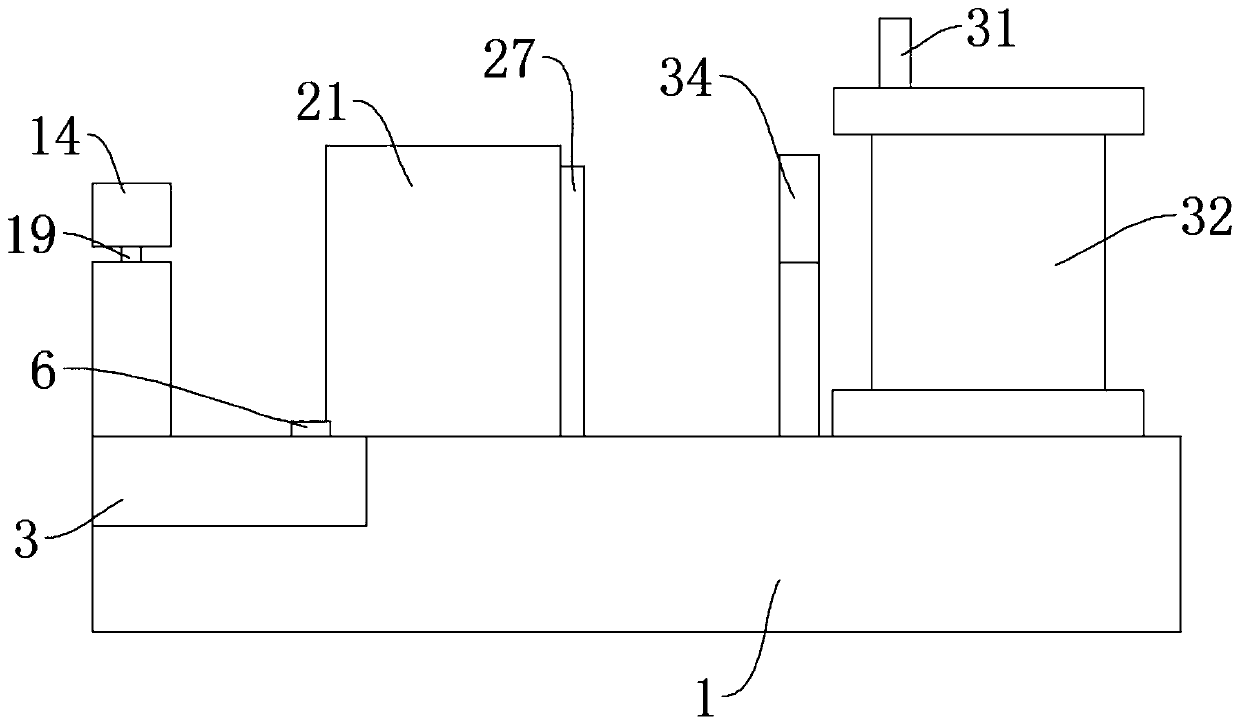

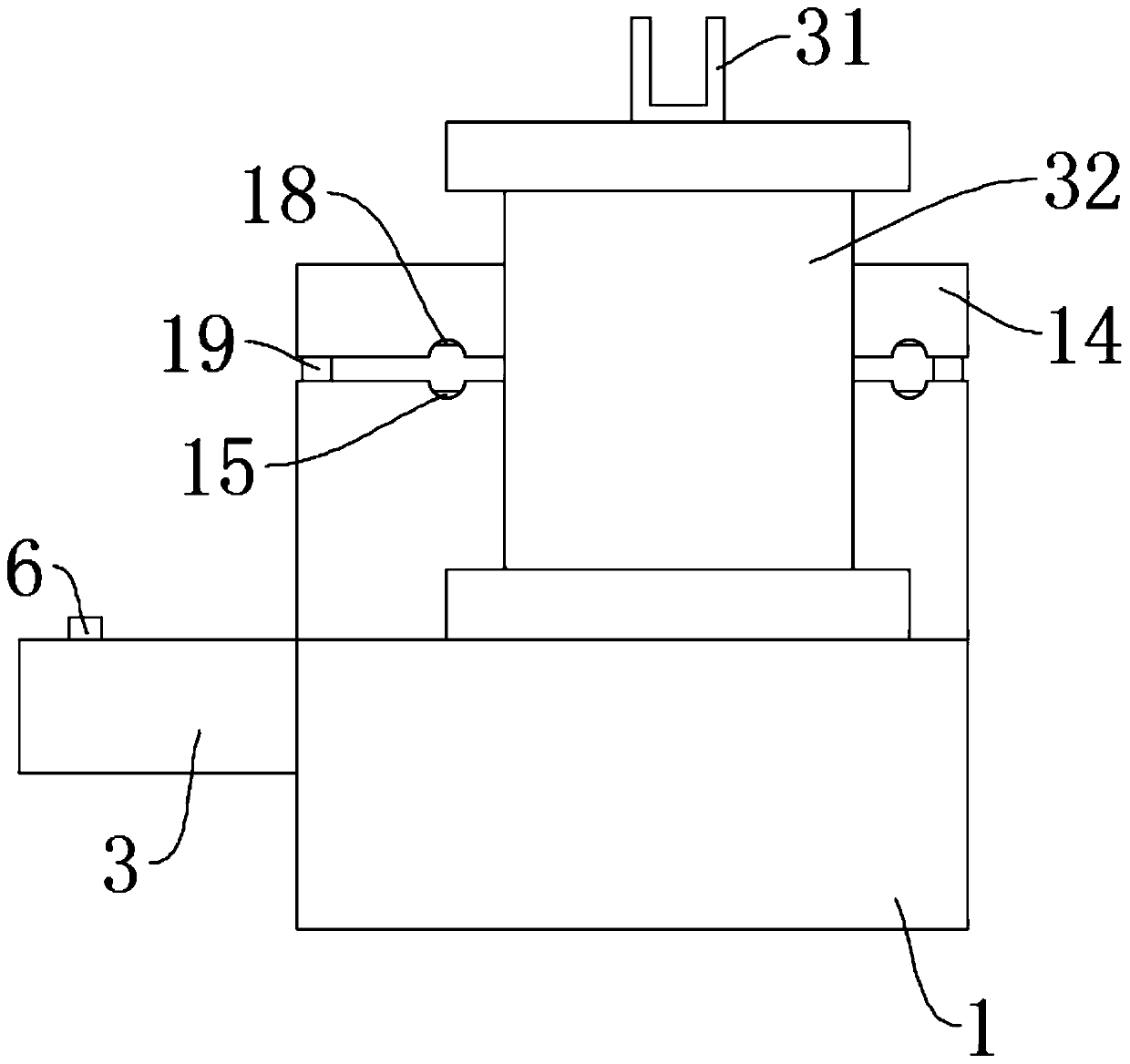

[0037] Below in conjunction with accompanying drawing this method is described further:

[0038] like Figure 1-Figure 10 As shown, a stranding device for composite cable production includes a stranding machine housing 1, a control device 2, a conveying device 13, a stranding device 20, and a collecting device 30. The front side of the stranding machine housing 1 is provided with a control device 2, The function of the control device 2 is to realize the fully automatic control function of the device. The upper side of the shell of the twisting machine 1 is provided with a conveying device 13. The function of the conveying device 13 is to realize the conveying function of the device. The twisting device 20 is used to realize the twisting operation of the device. The twisting device 20 is provided with a collecting device 30 on one side, and the collecting device 30 is used to realize that the device collects the cables. Circuit board 4, control chip 5, power switch 6, numeric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com