Stirrer for vertical polymer tank

A technology for polymers and mixers, applied in the direction of mixer accessories, mixers, mixers with rotating stirring devices, etc., can solve the problems of motor damage, increase the cost of use, and the inability to achieve high-viscosity polymers, etc., to increase the use of The effect of long service life, satisfying stirring, and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

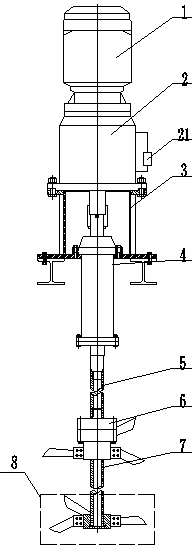

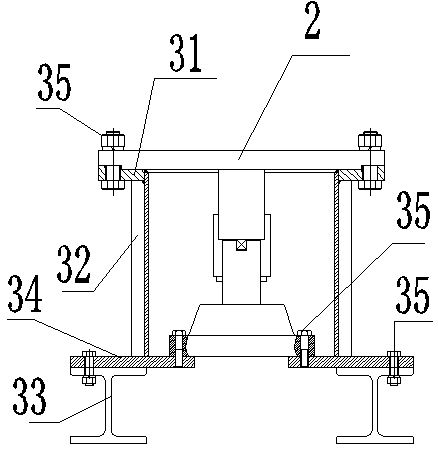

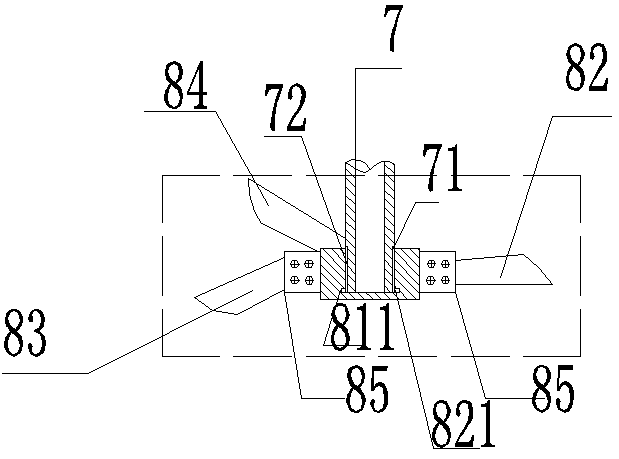

[0017] like Figure 1-3 As shown, a mixer for a vertical polymer tank includes a motor 1, a planetary reducer 2, a reducer bracket 3, an upper shaft support cylinder 4, an upper shaft 5, a coupling 6, a lower shaft 7, and a blade assembly 8 , the planetary reducer 2 is connected with the motor 1, the planetary reducer 2 is installed on the reducer bracket seat 3, the planetary reducer 2 is connected with the upper shaft 5, and the upper shaft 5 is installed There is an upper shaft support cylinder 4, one end of the coupling 6 is connected to the upper shaft 5, and the other end of the coupling 6 is connected to the lower shaft 7, and the lower shaft 7 is provided with a blade assembly 8, so The lower shaft 7 is provided with a limiting groove 71, and a mounting sleeve 72 is installed in the limiting groove 71, and an annular boss 721 is provided on the mounting sleeve 72, and the blade assembly 8 includes a connecting sleeve 81 , blade one 82, blade two 83, blade three 84, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com