Environment-friendly and energy-saving hogwash separation mechanism

A technology of environmental protection, energy saving and separation mechanism, which is applied in the direction of water/sewage treatment, water/sewage treatment equipment, multi-stage water/sewage treatment, etc. The effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

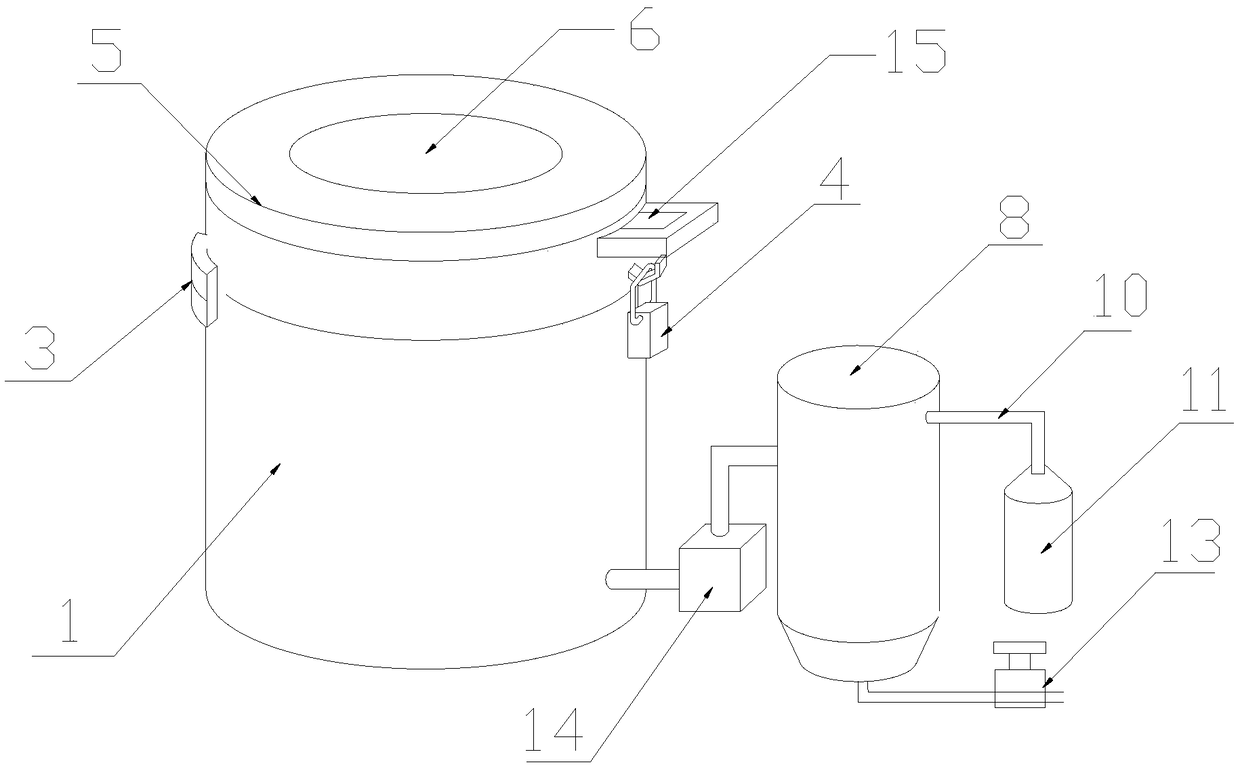

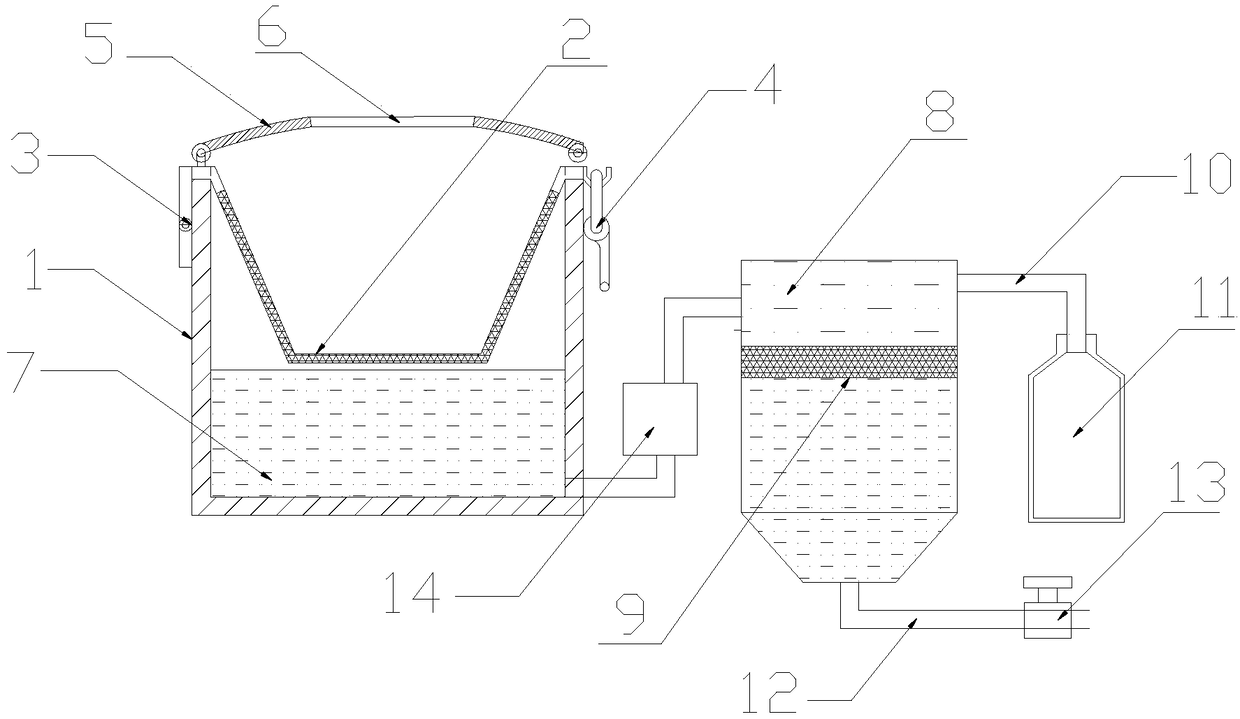

[0017] Embodiment 1: as Figure 1-2 As shown, an environmental protection and energy-saving swill separation mechanism of the present invention includes a device main body 1, a filter basket 2, a top cover 5 and an oil-water separation tank 8, the device main body 1 is a cylindrical cylinder, and the middle part of the device main body 1 inner cavity is installed The filter basket 2, the filter basket 2 is a cone-shaped bucket structure, one side of the top of the filter basket 2 is connected to the top side of the device main body 1 through a hinge 3, and the other side of the top of the filter basket 2 is opened and closed The lock 4 is fastened on the other side of the top of the main body 1 of the device, the top of the filter basket 2 is fastened with a top cover 5, the middle part of the top cover 5 is provided with a feeding port 6, and the bottom of the main body 1 of the device is filled with an oil-water mixture. Liquid 7, an oil-water separation tank 8 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com