Harmless discharge range hood based on ultrasonic generator for efficiency improving

The technology of a range hood and a generator is applied in the field of harmless emission range hoods, which can solve the problems of easy adhesion of oil fume scale to a range hood separation pipe, pollution of the atmospheric environment by discharged exhaust gas, low efficiency of flue gas purification, etc., so as to achieve harmless emission. The effect of chemical emission, high flue gas purification efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

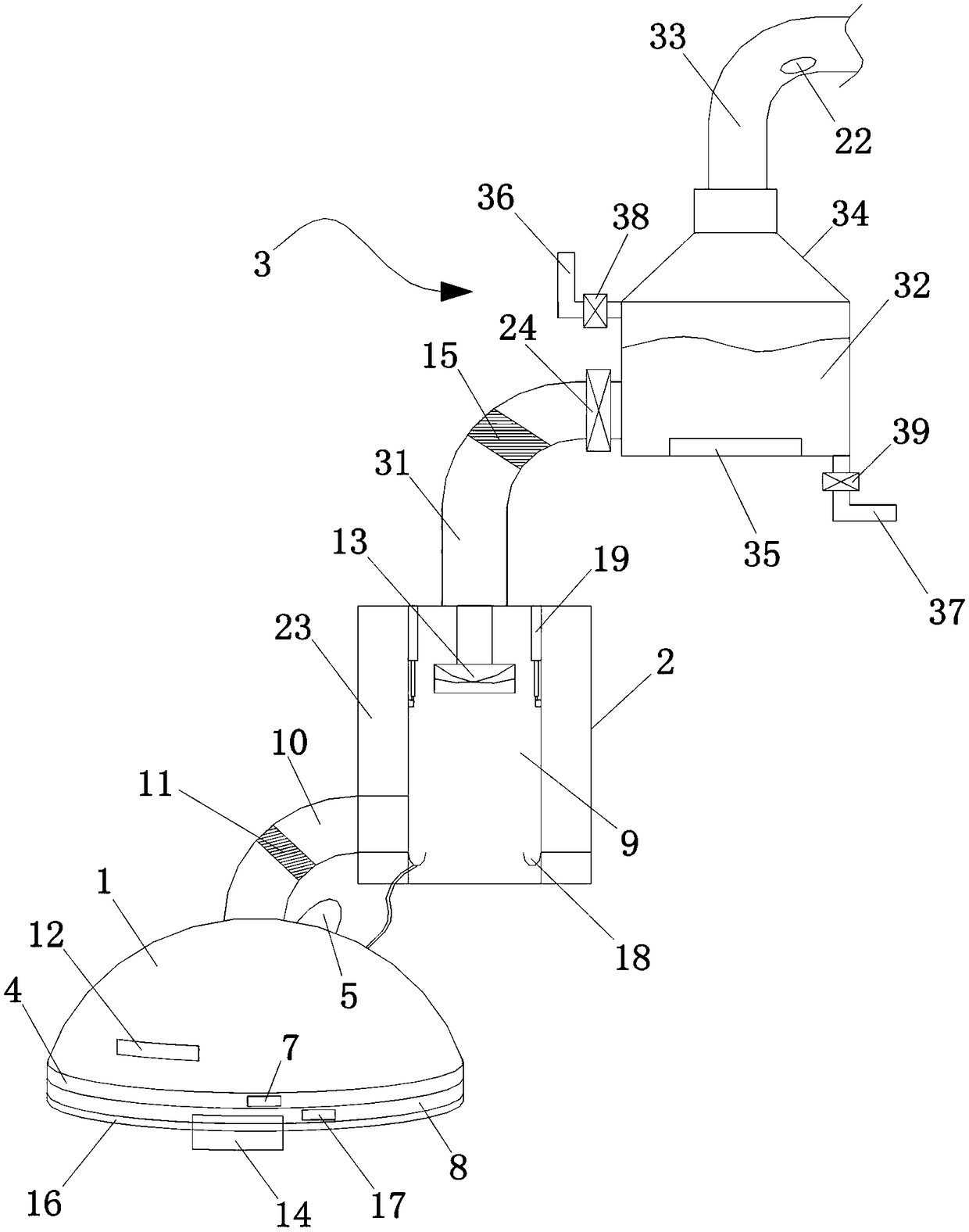

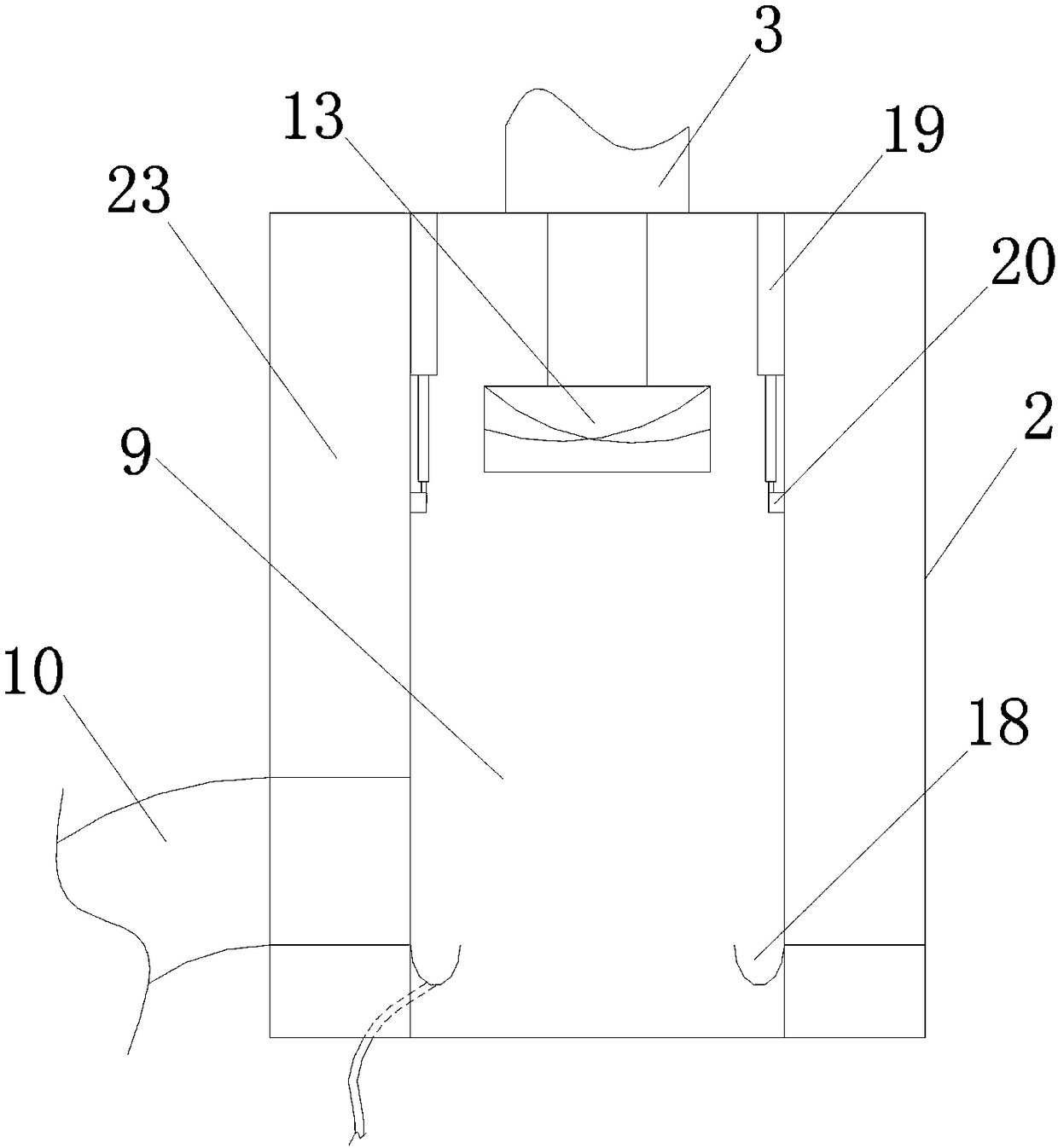

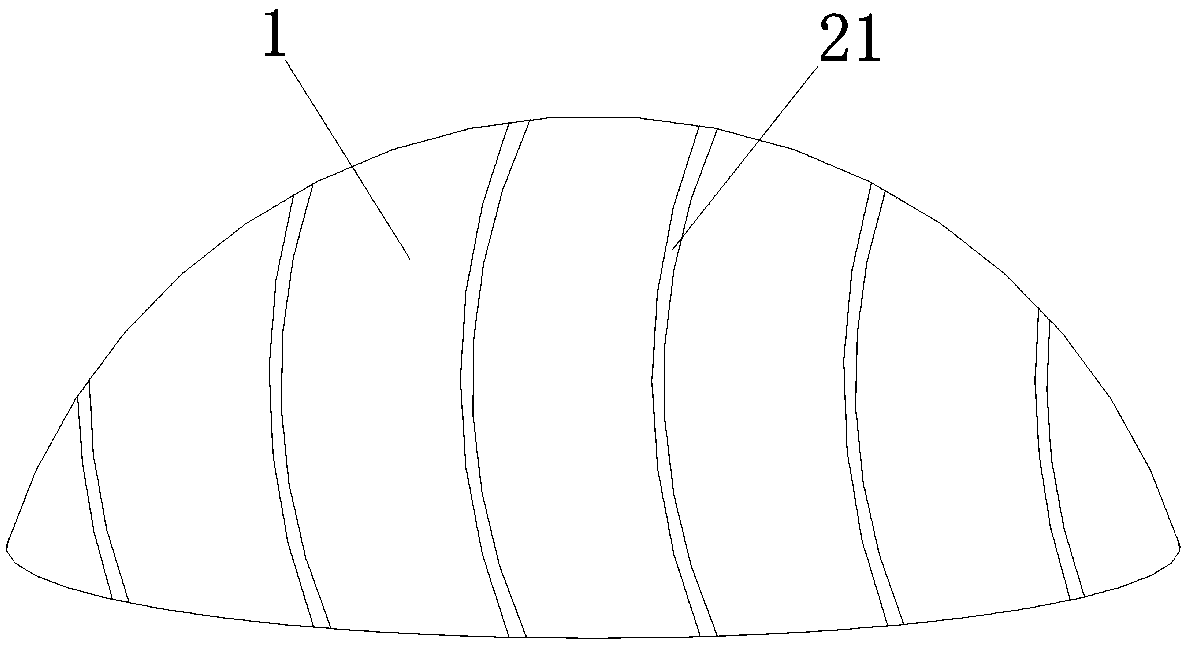

[0028] Such as Figure 1-4 As shown, the harmless exhaust range hood provided by the present invention based on the efficiency improvement of the ultrasonic generator has a simple structure, a scientific and reasonable design, and is easy to use. A small amount of soot mixture condensed on the bottom prevents this part of the soot mixture from dripping onto the kitchen stove, reducing the work intensity of the user, and at the same time can fully purify the exhaust gas, realize the harmless emission of waste gas, and have high flue gas purification efficiency. The present invention comprises a range hood 1, a fume separation box 2 connected to the top of the fume hood 1, and a waste gas exhaust device 3 connected to the top of the fume separation box 2; the fume h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com