Cabin air pipe steam trap

A technology for pipe traps and cabins, applied in steam traps, mechanical equipment, etc., can solve the problems of not being able to fill with liquid, and unable to process vent pipes at the top of the cabin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

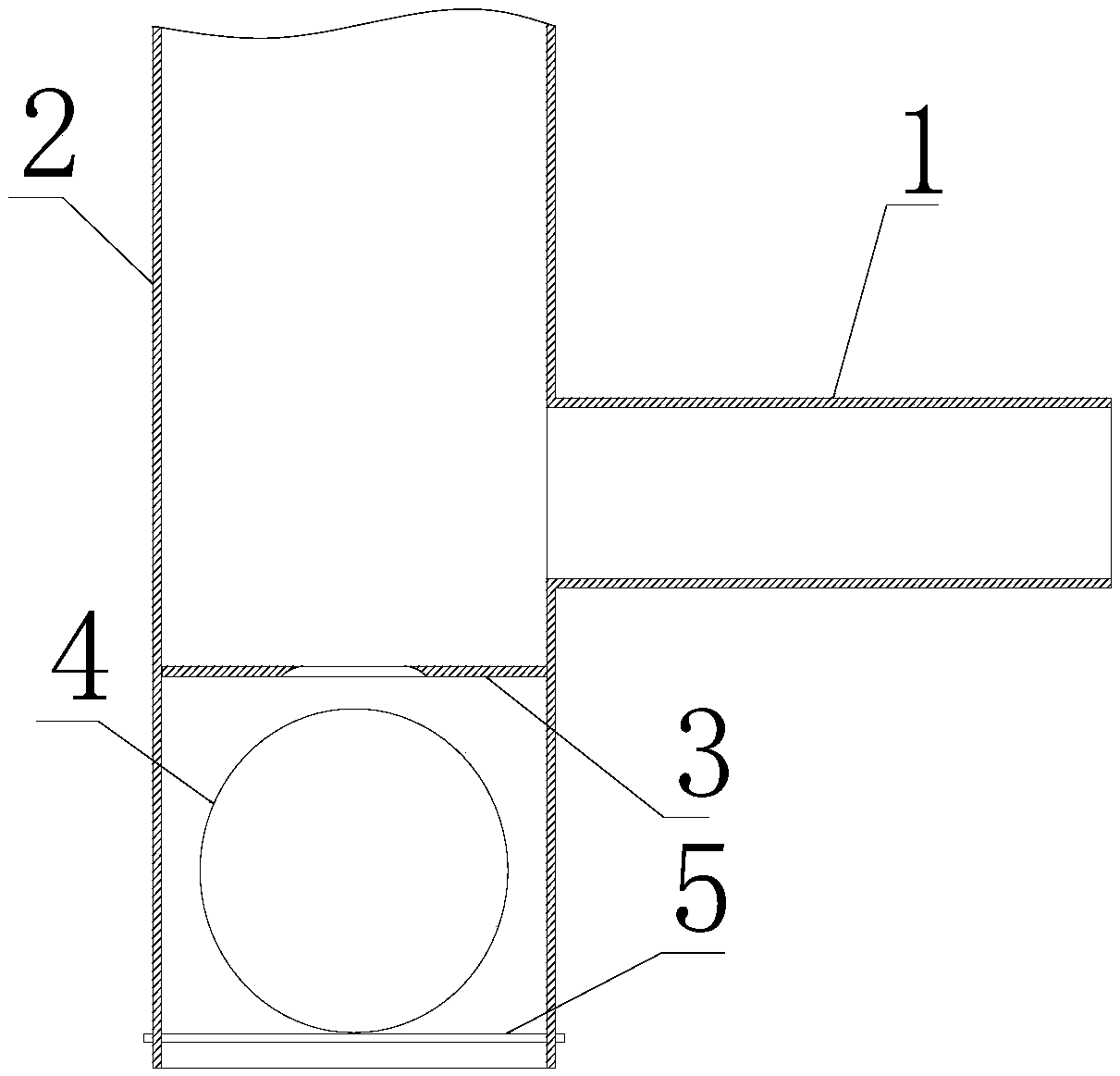

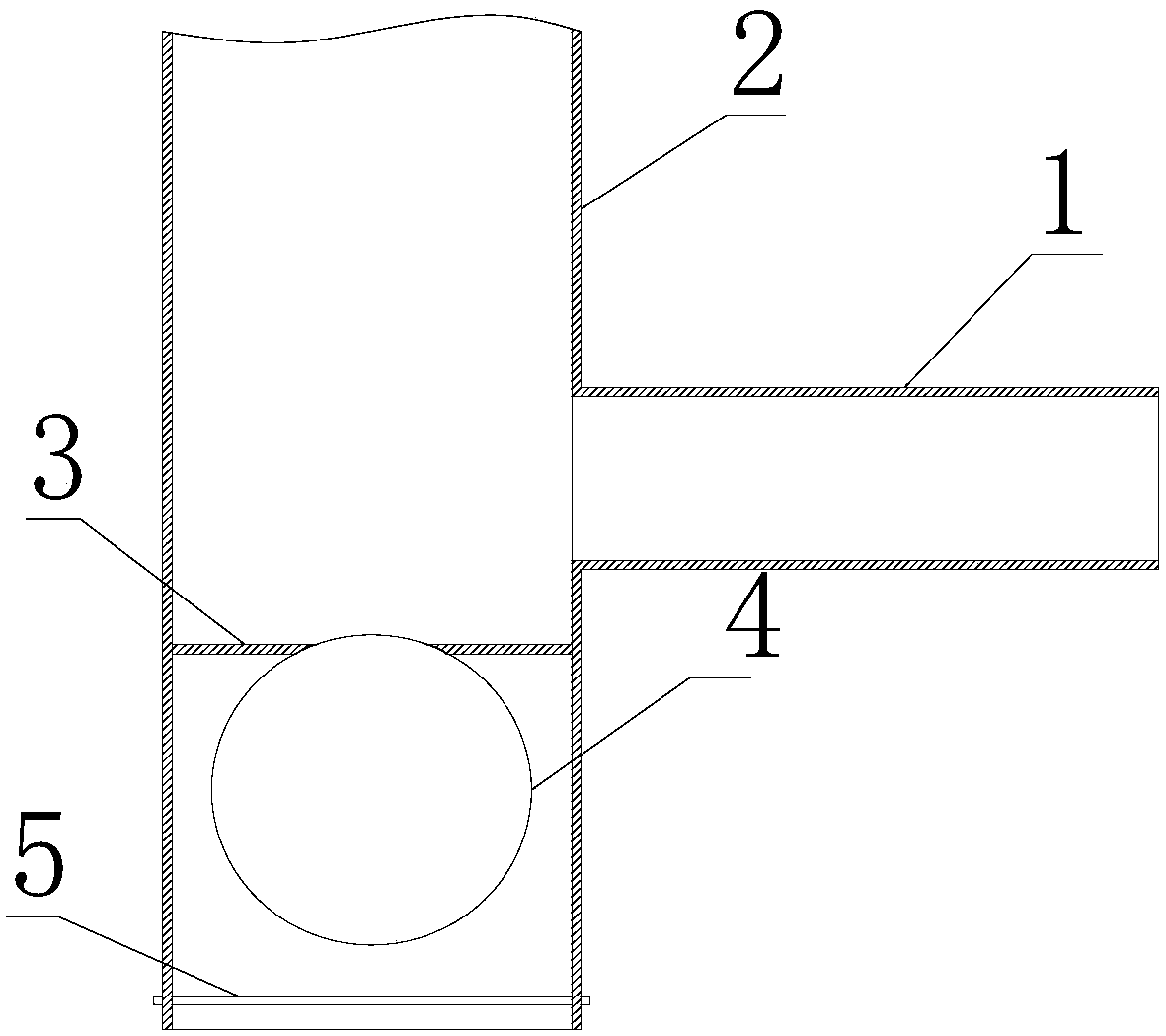

[0017] see Figure 1-2 , a cabin air pipe steam trap, including a vent pipe 1 passing through the side wall of the cabin, and a main pipe 2, the vent pipe 1 is connected to the side wall of the main pipe 2, and the vent pipe 1 is provided with a A valve assembly that opens when the liquid level is lower than the bottom of the main pipe 2 and closes when the liquid level is higher than the bottom of the main pipe 2; the position of the valve assembly is lower than the position where the vent pipe 1 is connected to the main pipe 2, and the The top of the main pipe 2 extends to the top of the cabin.

[0018] During use, the vent pipe 1 is installed on the side wall of the cabin, and the top of the main pipe 2 is extended to the top wall of the cabin. When the liquid in the cabin reaches the bottom of the main pipe 2, if the liquid continues to rise, the valve assembly is closed, and the gas flows from the main pipe. The top of 2 enters the vent pipe 1, and when the liquid rises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com