Management system and method of paint buckets

A technology of management system and management method, which is applied in the field of electronic equipment, can solve the problem of untraceable process of paint bucket distribution to recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

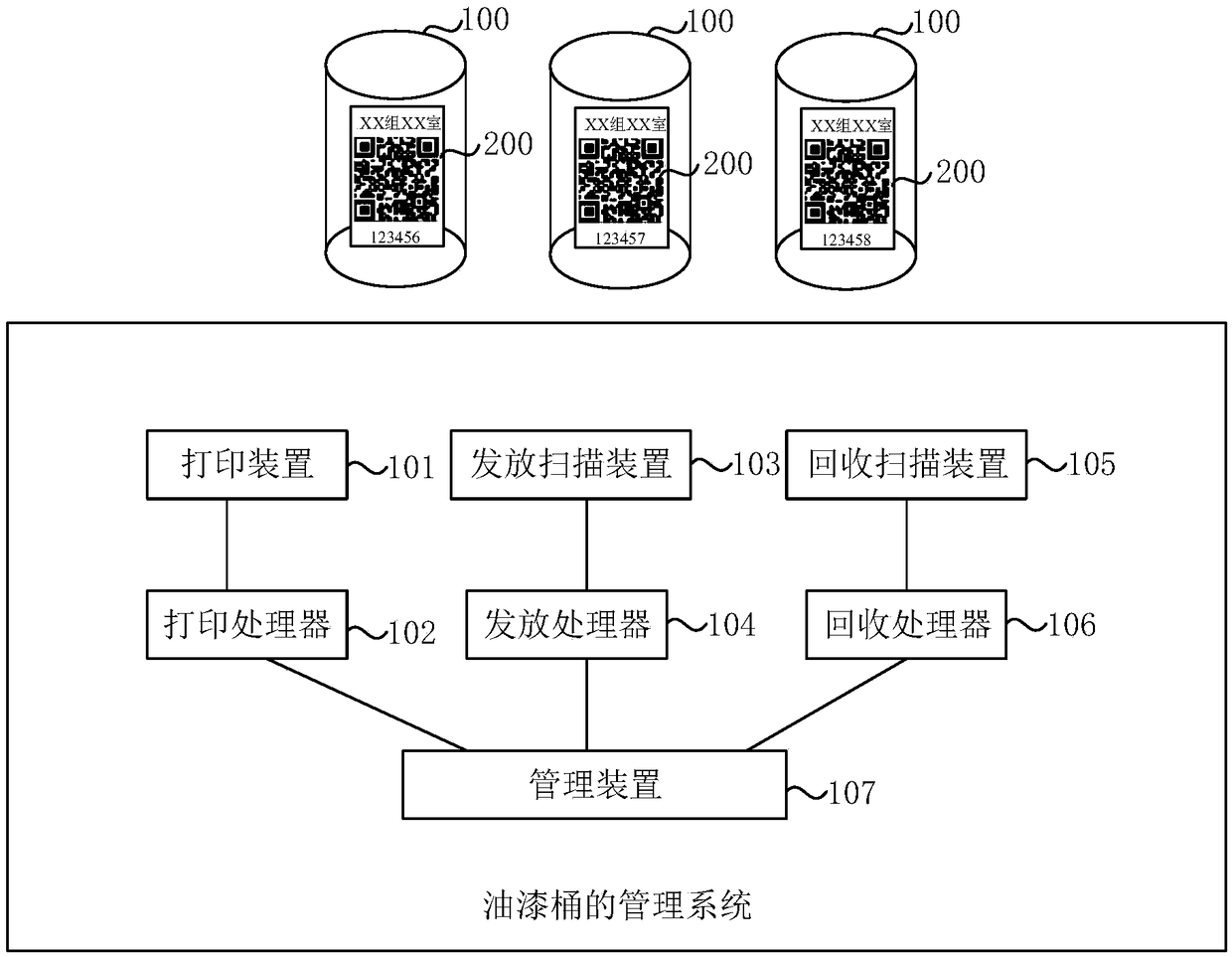

[0033] This embodiment provides a management system for paint buckets, such as figure 1 As shown, the paint bucket management system includes a printing device 101 , a printing processor 102 , an issuing scanning device 103 , an issuing processor 104 , a recycling scanning device 105 , a recycling processor 106 , and a management device 107 .

[0034] The printing device 101 is electrically connected to the print processor 102, the issuing scanning device 103 is electrically connected to the issuing processor 104, the recycling scanning device 105 is electrically connected to the recycling processor 106, and the management device 107 is respectively connected to the printing processor 102, the issuing processor 104, The recovery processor 106 is electrically connected.

[0035] The paint bucket management system can distribute the printing device, the distribution scanning device, the recycling scanning device and the management device in different locations, realize the flexi...

Embodiment 2

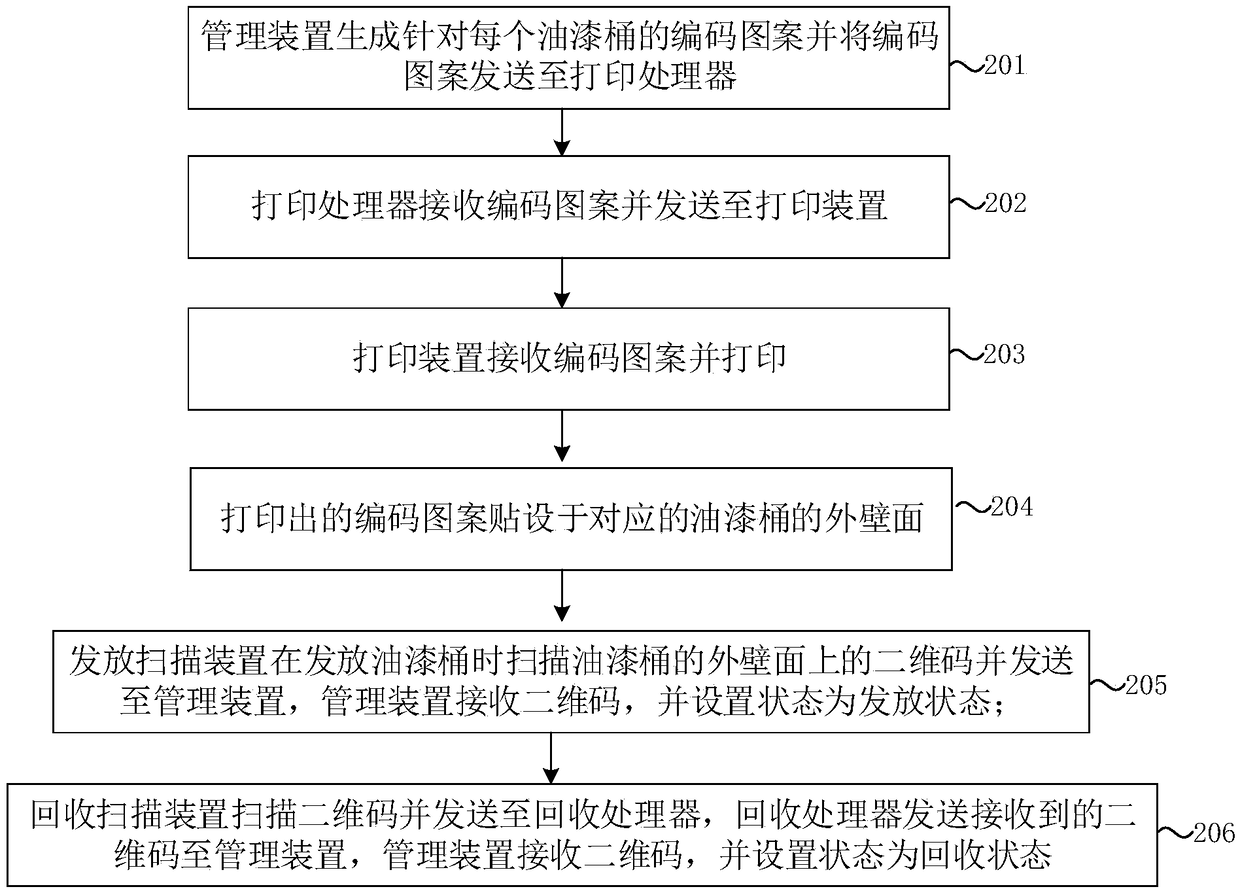

[0047] This embodiment provides a paint bucket management method. The paint bucket management method is implemented based on the paint bucket management system in Embodiment 1. The paint bucket management method includes:

[0048] Step 201, the management device generates a coding pattern for each paint bucket and sends the coding pattern to the print processor.

[0049] Step 202, the printing processor receives the coding pattern and sends it to the printing device.

[0050] The coding pattern also includes a number, which corresponds to the two-dimensional code.

[0051] Numbers consist of numbers and / or letters.

[0052] The coding pattern also includes using at least one of ship number, crew information, paint type and batch number.

[0053] Step 203, the printing device receives and prints the coding pattern;

[0054] Step 204, the printed coding pattern is pasted on the outer wall of the corresponding paint bucket;

[0055] like figure 1 As shown, the printed coding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com