Processing contoured wrap-around labels from roll

A labeling and labeling technology, applied in the direction of labels, labeling machines, packaging, etc., can solve the problems of high susceptibility to interference, high waste rate, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

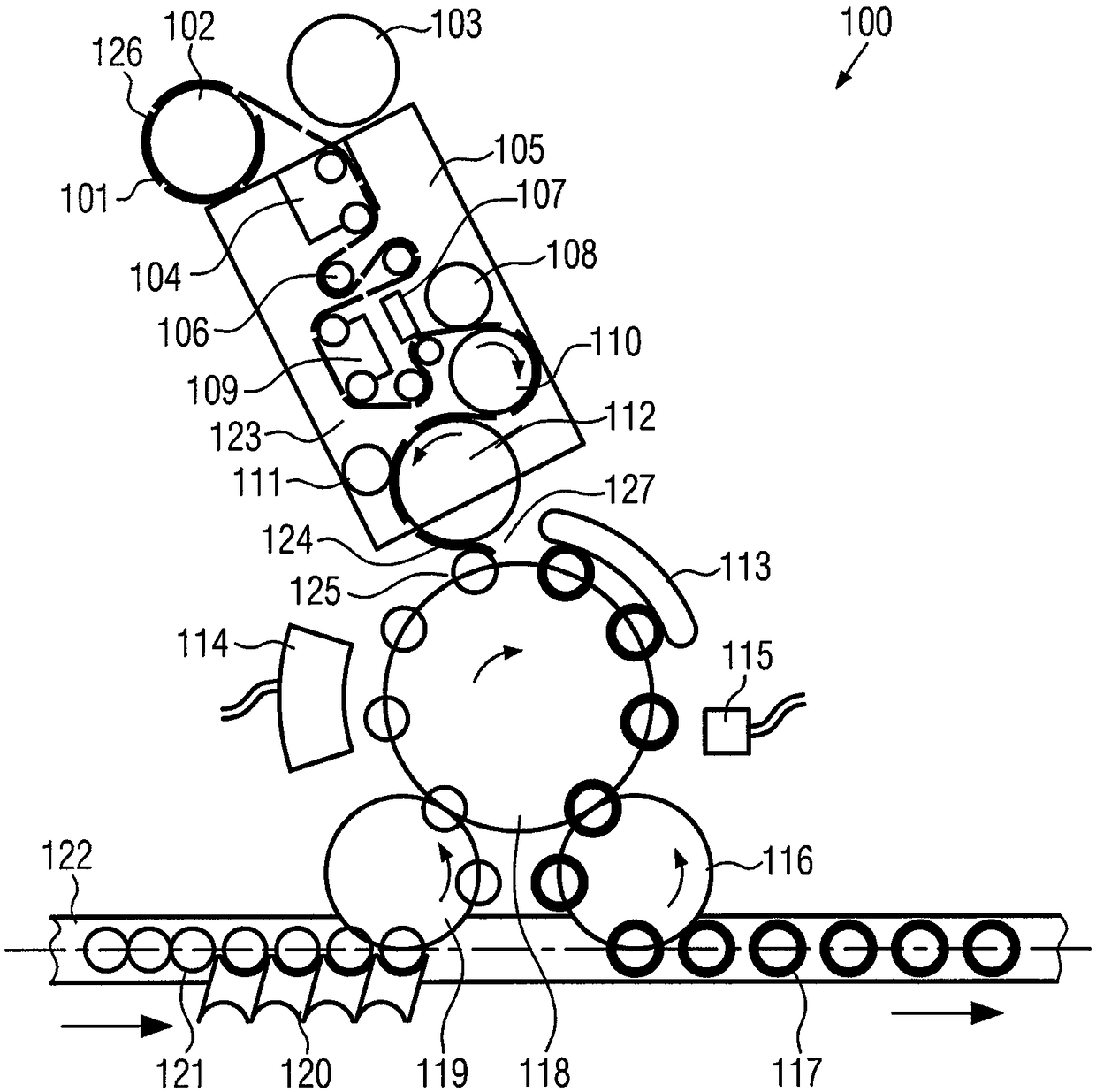

[0068] figure 1 An exemplary labeling apparatus 100 is shown for processing labels 124, 126 of an arbitrary label shape of a label web 101, for example for processing a continuous label web for wrap-around labeling of articles such as containers 121 Labeling 126 of 101, the labeling apparatus comprises transport means 123 for transporting the label web 101 along a predetermined transport path.

[0069] In addition, the exemplary labeling apparatus 100 includes an exemplary positioning detection device 107 for detecting the positioning of the label web 101 and / or for detecting the positioning of the label 126 of the label web 101, and includes an exemplary web A web travel adjustment device 109 is configured to perform a change in the positioning of the label web.

[0070] For example, the position detection device 107 embodied as a camera can be configured in such a way that at least one position can be obtained from at least one feature of the label web 101 and / or from at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com