Header for combine harvester

A technology for combine harvesters and headers, applied to harvesters, applications, cutters, etc., which can solve the problems of easy fatigue damage to parts on the right side of the header, large difference in vibration displacement between the left and right sides of the header, and increased loss of crop division. , to achieve the effect of reducing the loss of the right parting grain, reducing the fatigue damage and reducing the amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

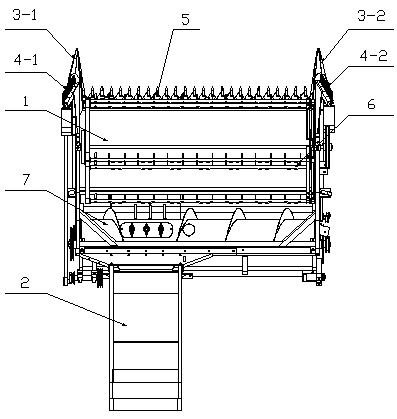

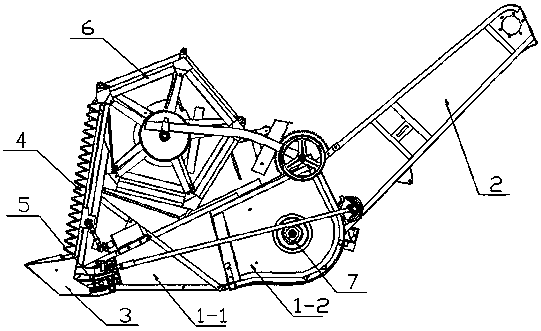

[0028] Example one: such as figure 1 As shown, a header for a combine harvester includes a header frame 1, a conveying trough 2, a crop divider 3, a double vertical cutter 4, a main cutter 5, a reel 6, and a screw conveyor 7 Conveying trough 2 is located at the rear left side of the forward direction of the header frame 1, and its center line is about 276mm-296mm from the left end of the header frame 1, and about 707mm-727mm from the right end of the header frame 1, 3 points for the grain divider It is the left crop divider 3-1 and the right crop divider 3-2, which are respectively arranged at the left front and right front of the forward direction of the rape header frame 1. The double vertical cutter 4 is divided into the left vertical cutter 4- 1 and the right vertical cutter 4-2, which are respectively arranged above the left crop divider 3-1 and the right crop divider 3-2. The main cutter 5 is located at the front end of the rape header frame 1 in the forward direction. Th...

Embodiment 2

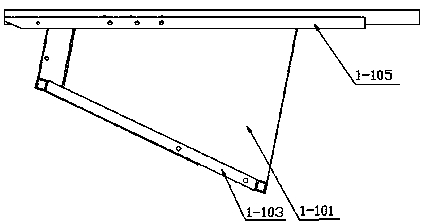

[0033] Embodiment 2: The composition of the parts of the header is exactly the same as in the first embodiment, but in order to realize that the rigidity of the components on the right side of the header frame 1 is greater than the stiffness of the components on the left side of the header frame 1, the supporting steel 1-107. The bottom connecting beam 1-207 and the steel 1-212 above the arc back plate are set in the form of variable cross-section with unequal stiffness to achieve the characteristics of unequal stiffness of the rape header.

Embodiment 3

[0034] Embodiment 3: The composition of the parts of the header is exactly the same as in the first embodiment, but in order to realize that the rigidity of the components on the right side of the header frame 1 is greater than the stiffness of the components on the left side of the header frame 1, the header frame 1 The left and right parts can be made of materials with different stiffness to achieve the characteristics of unequal stiffness of the rape header.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com