Template automatic cleaning device

An automatic cleaning and template technology, applied in cleaning methods and tools, cleaning methods using tools, ceramic molding machines, etc., can solve the difficulty of template working surfaces and high work intensity, affecting the health of staff, low cleaning efficiency, dust, etc. problems, to achieve the effect of avoiding harm to health, easy cleaning, and prolonging the pouring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

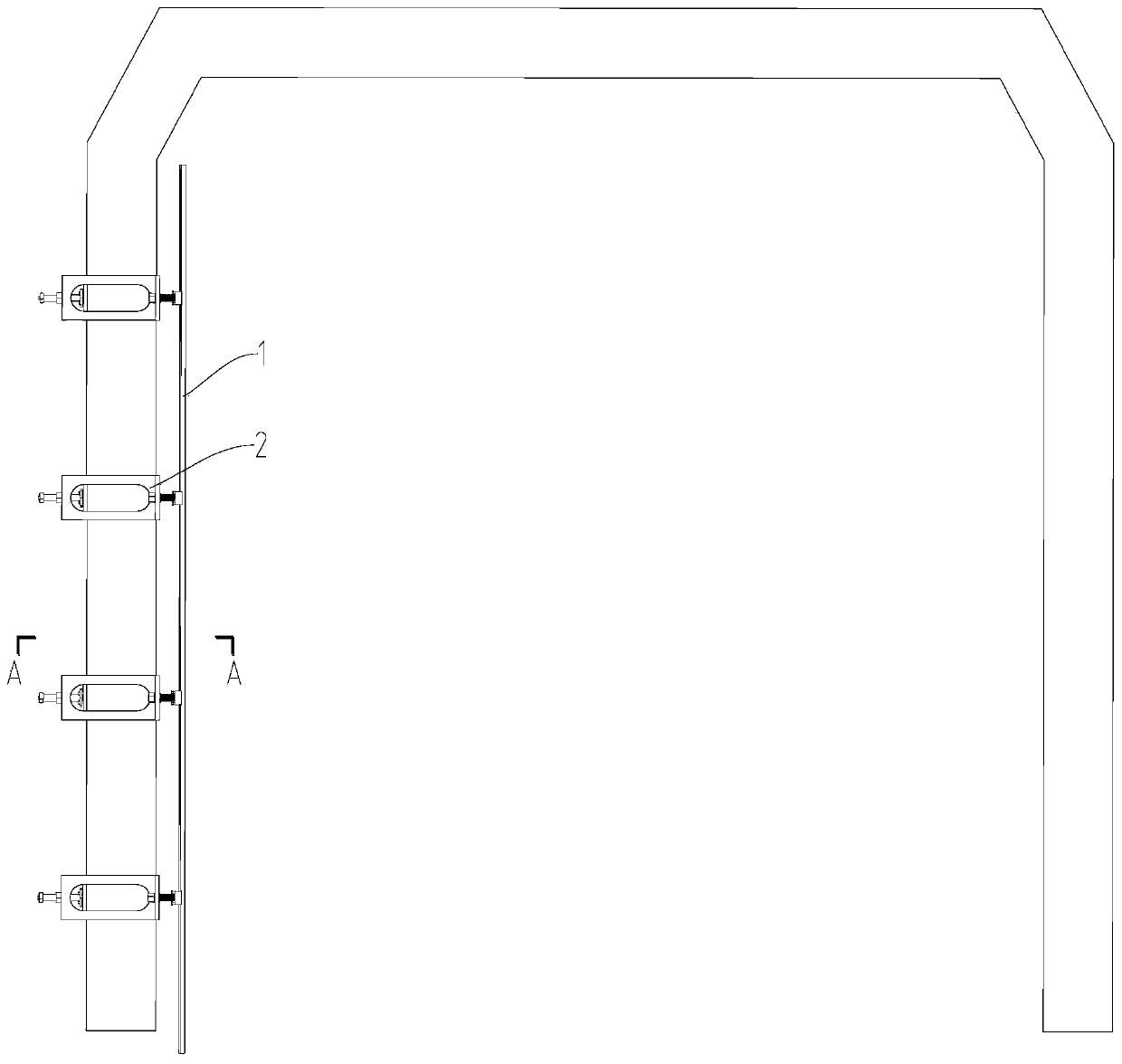

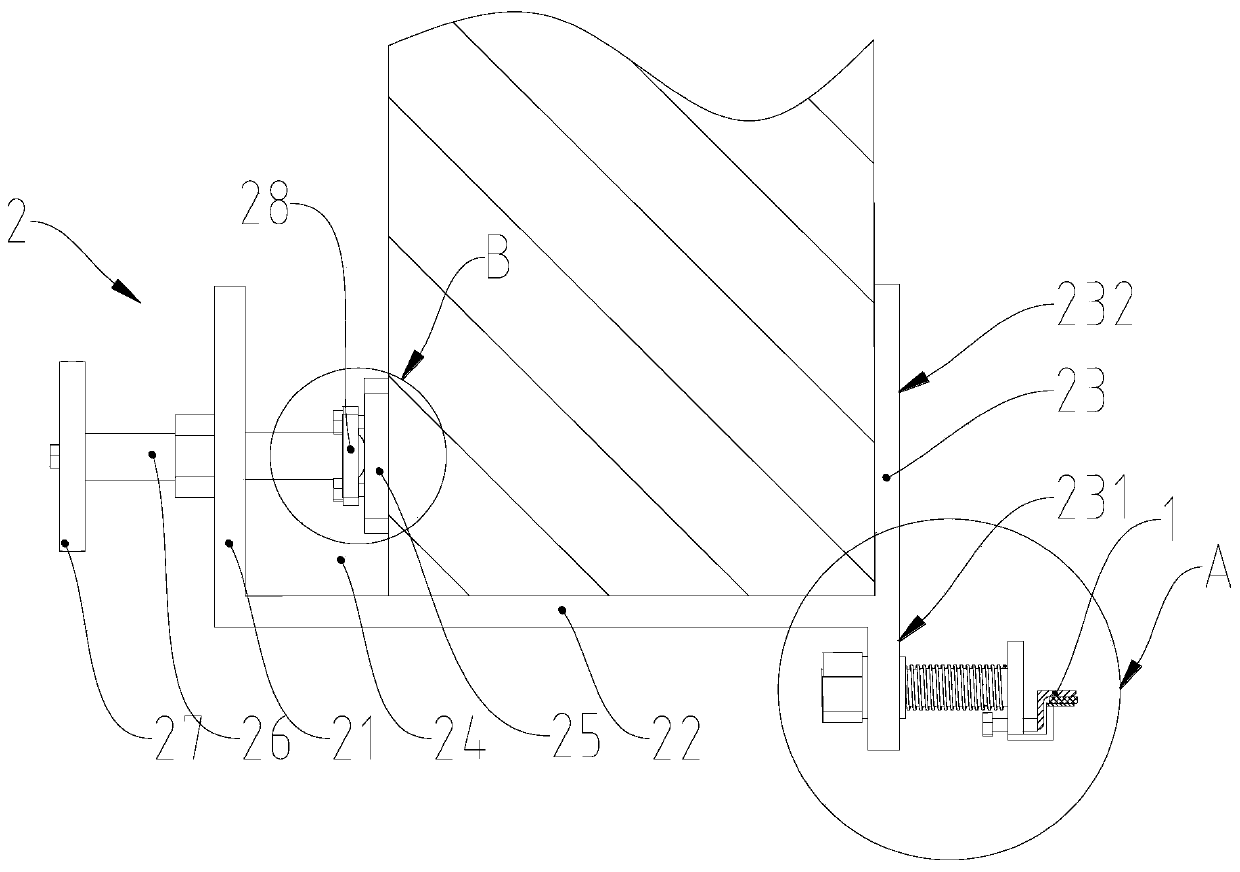

[0025] Such as figure 1 , figure 2 and image 3 As shown, the template automatic cleaning device includes a scraper 1, a set of fixed supports 2 arranged along the length direction of the scraper 1, and a connection structure connecting each fixed support 2 in the group with the scraper 1;

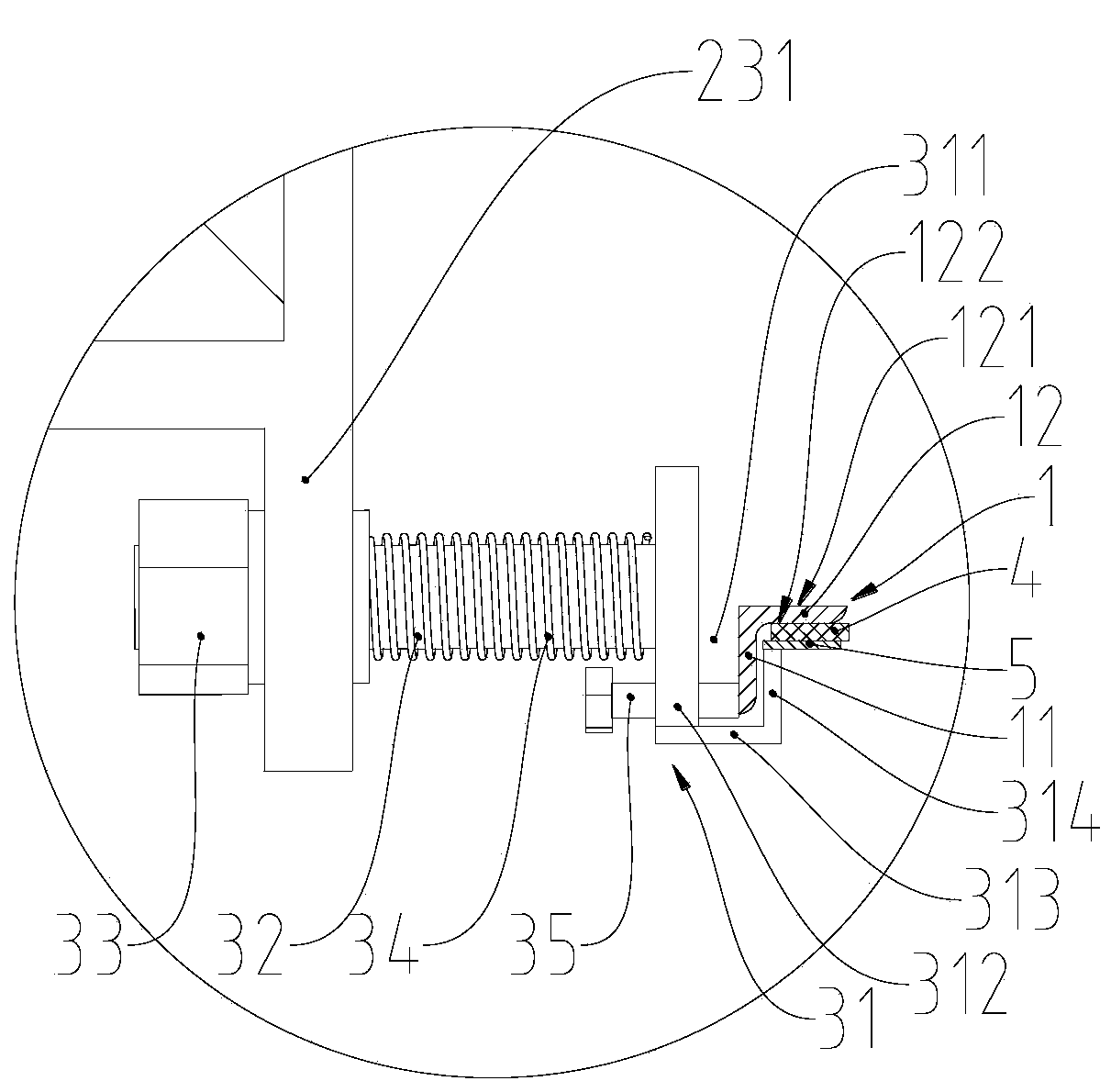

[0026] The connection structure includes a scraper clamping bracket 31, a connecting screw 32 and a nut 33; one end of the connecting screw 32 is fixedly connected with the scraper clamping bracket 31, and the other end passes through the fixed support 2 and is threadedly connected with the nut 33. 32 is overlaid with a compression spring 34, and the compression spring 34 is located between the fixed support 2 and the scraper clamping bracket 31;

[0027] The scraper 1 includes a mounting portion 11 and a working portion 12, the mounting portion 11 is detachably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com