Release agent automatic brushing device

A technology of release agent and spraying device, applied in the direction of spraying device, etc., can solve the problems of inconvenient application, uneven application, low efficiency, etc., and achieve the effects of convenient application, high application efficiency, and prolonged pouring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

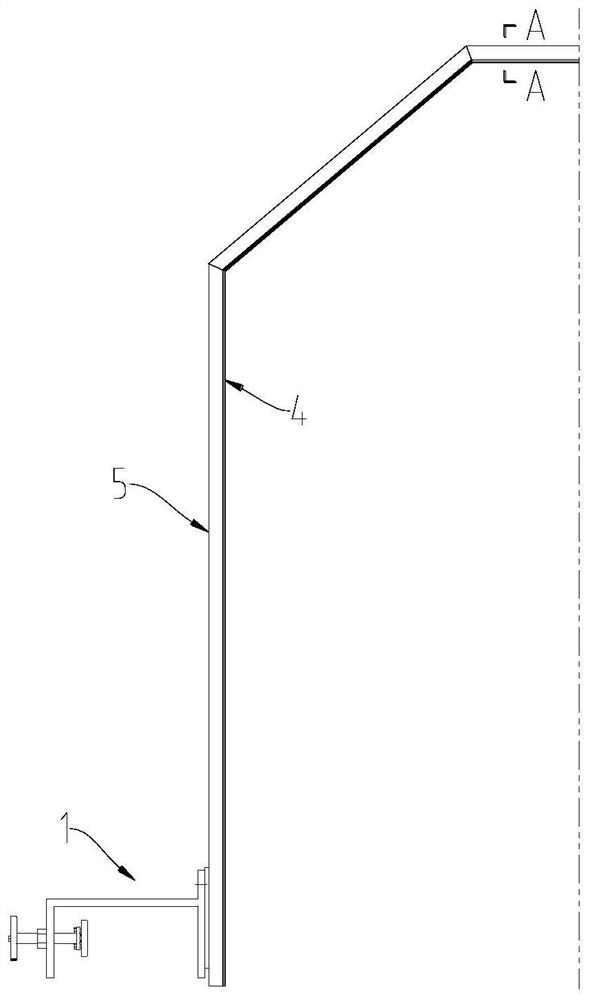

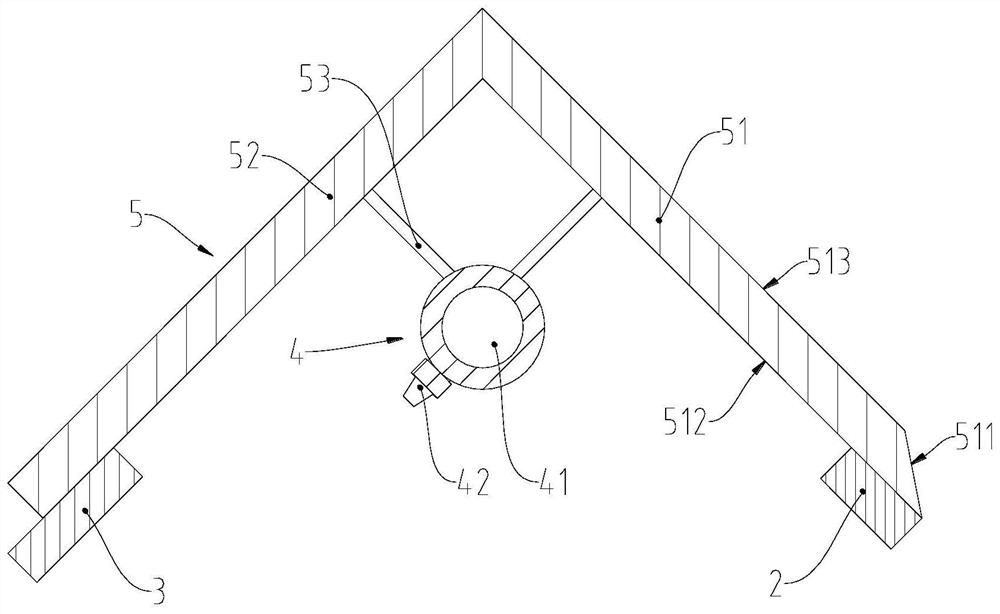

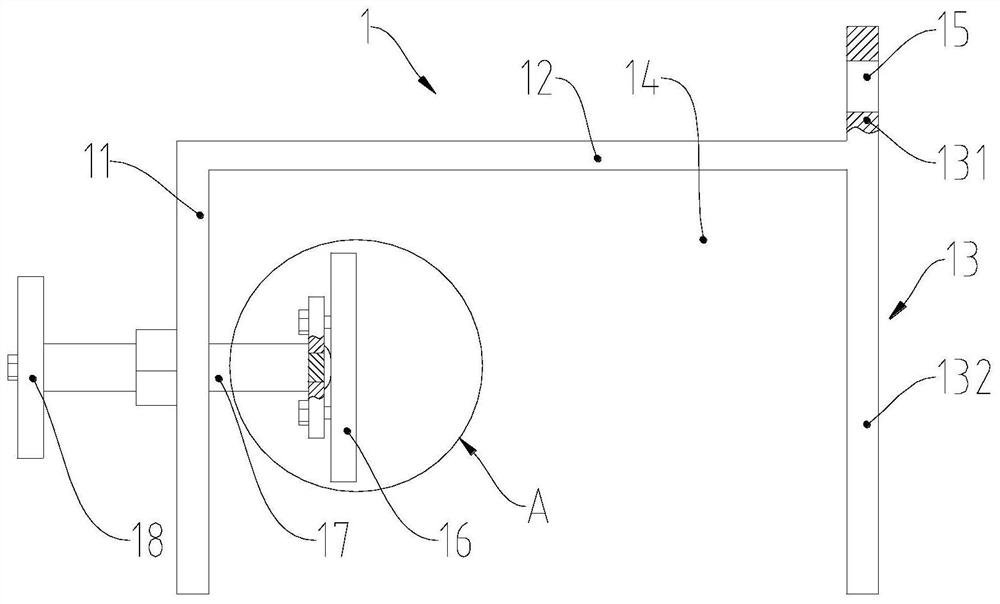

[0029] like figure 1 and figure 2 As shown, the release agent automatic brushing device includes a spraying device 4, a cleaning device 2, a smearing device 3 and a fixed support 1 for installing the spraying device 4, cleaning device 2 and smearing device 3 on the pipe gallery;

[0030] The spraying device 4 includes a spraying pipe 41 for conveying the release agent and a group of nozzles 42 for spraying the release agent. The spraying pipe 41 is a gate shape adapted to the cross-sectional shape and size of the pipe gallery, and a group of nozzles 42 are sprayed along the The extension direction of the tube 41 is set;

[0031] The cleaning device 2 is in the shape of a gate adapted to the cross-sectional shape and size of the pipe gallery;

[0032] The smearing device 3 is in the shape of a door adapted to the cross-sectional shape and size of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com