Hoisting method for concrete production

A technology for concrete and hanging tanks, applied in construction, infrastructure engineering and other directions, can solve problems such as insignificant effects, and achieve the effects of reducing pouring costs, obvious economic and social benefits, and improving pouring strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

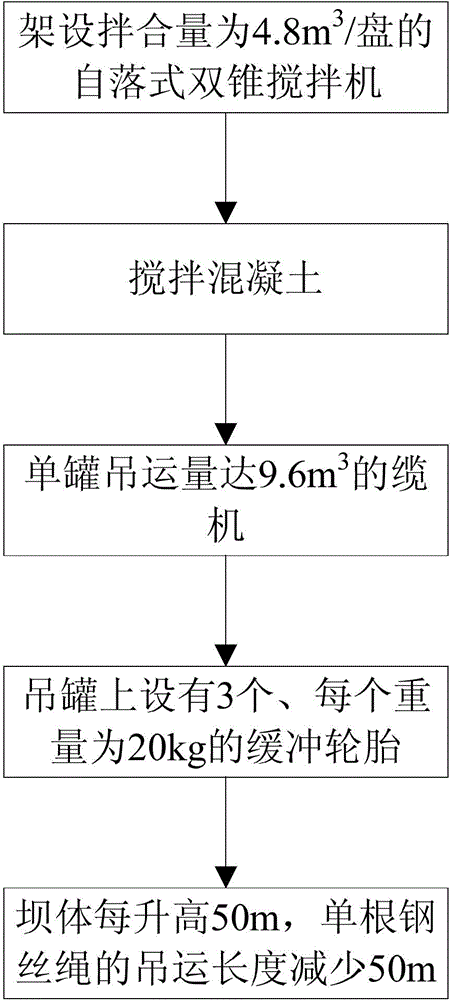

[0022] see figure 1 , the concrete production lifting method of the present invention, comprises the steps:

[0023] Step 1. In the mixing building, there are two trays and the mixing capacity is 4.8m 3 Self-falling double-cone mixer for mixing concrete;

[0024] Step 2: Use a single tank to lift up to 9.6m 3 The concrete is lifted by a cable crane, and three buffer tires each weighing 20kg are arranged on the hanging tank of the cable crane. The hoisting length is continuously reduced, specifically, the hoisting length of a single steel wire rope is reduced by 50m for every 50m rise of the dam body.

[0025] It can be seen from the technical scheme of the present invention that in order to achieve the purpose of improving the single-tank lifting capacity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com