A color marking printing process of ribbon

A screen printing machine and ribbon technology, applied in printing, printing devices, etc., can solve the problems of unable to meet the performance requirements of color marking of high-grade ribbons, monotonous color combination, and no anti-counterfeiting function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

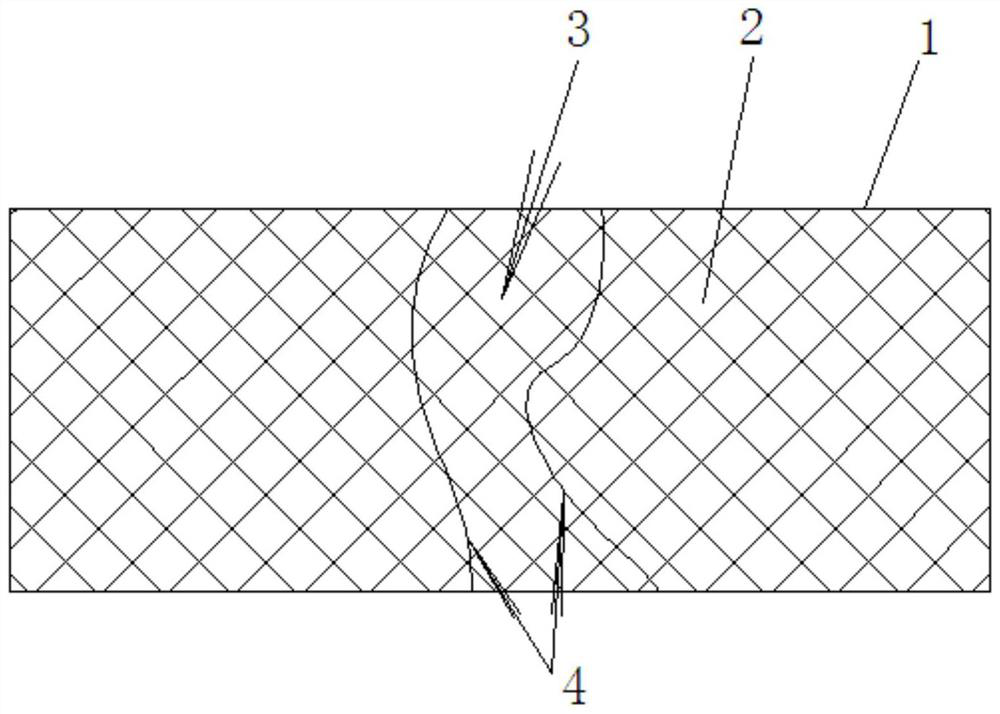

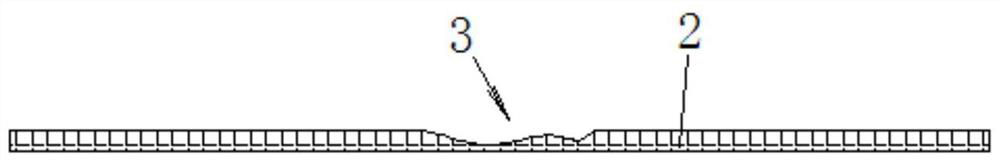

[0025] Such as Figures 1 to 2 Shown is an embodiment of a color marking printing process of a ribbon of the present invention, including making a color separation screen 1 according to the pattern and color to be printed, installing the prepared screen 1 on a multi-color screen printing The color separation overprint of the ribbon is carried out on the machine, the color separation screen 1 is made with an overprint area 3, and the color separation screen 1 adopts a multi-axis CNC machine tool with three axes or more to carry out the overprint area 3. The thickness of the screen gradient processing.

[0026] In the above-mentioned embodiment, the overpri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com