Preparation method and application of rhamnolipid

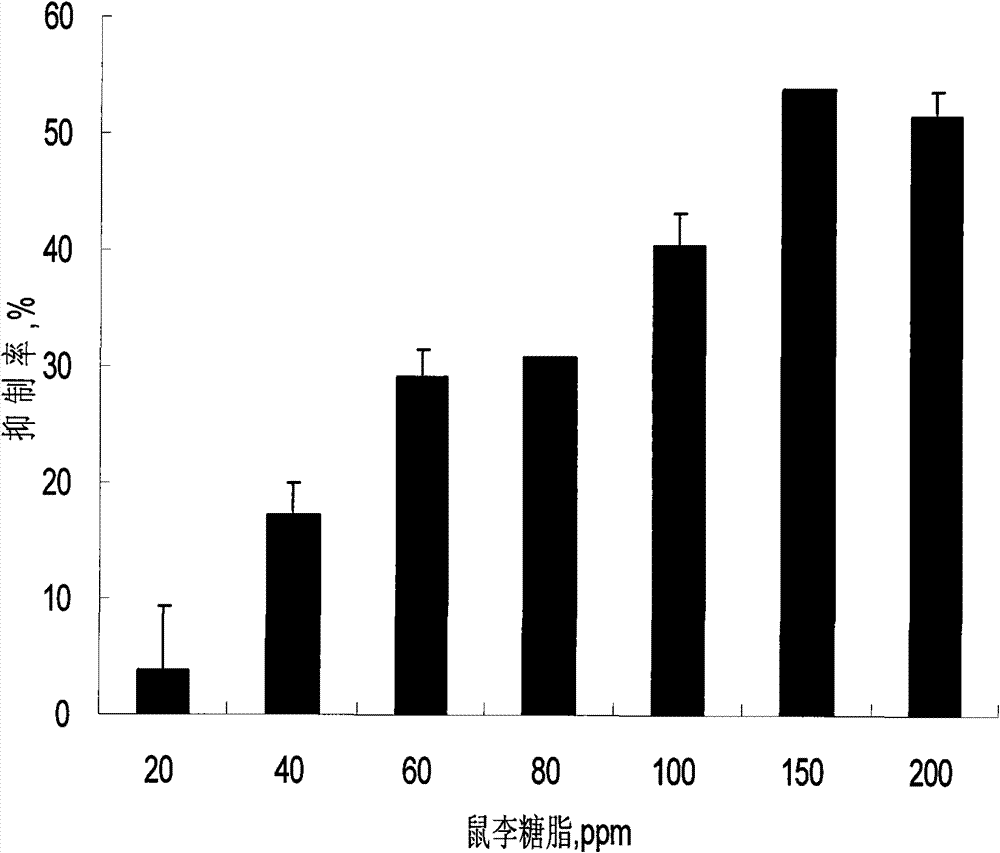

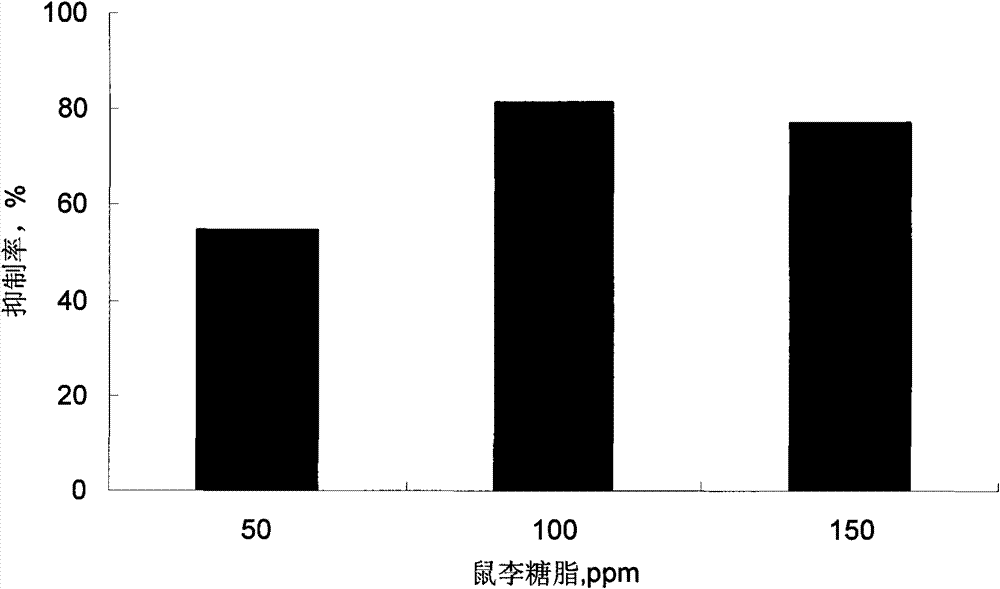

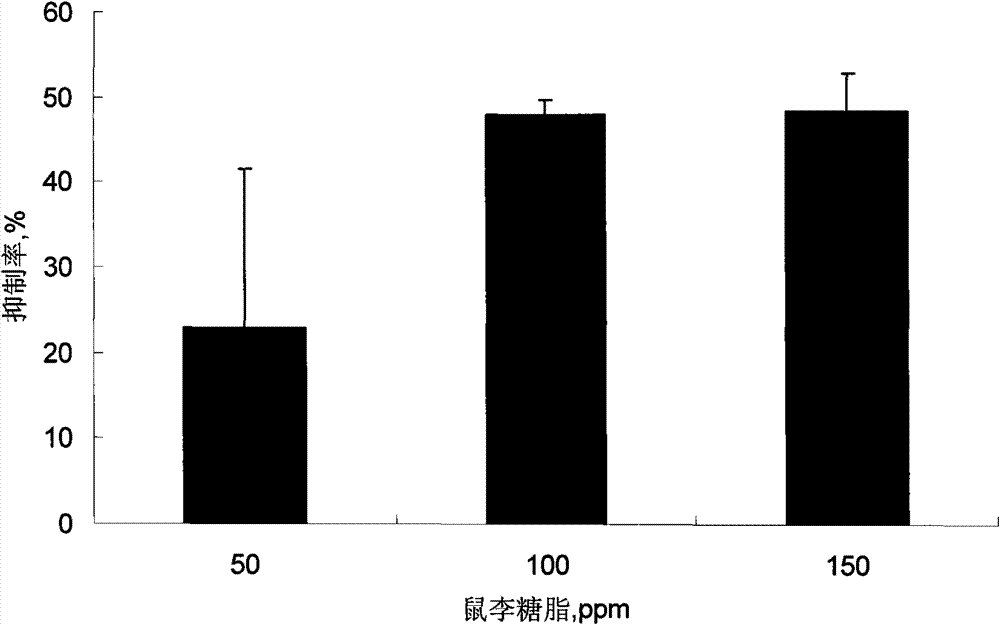

A technology for rhamnolipid and seeds is applied in the field of preparation of rhamnolipid, which can solve the problems of large processing workload, unfavorable human health and environmental protection, difficulty in sedimentation, etc., so as to reduce the harm of human body and the environment and inhibit plant growth. Fungal diseases, the effect of reducing sludge disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of this rhamnolipid, concrete steps are as follows:

[0038] 1. Strain cultivation: Inoculate the Pseudomonas aeruginosa ZJU-211 strain into the shake flask seed medium for cultivation, the temperature is 32-38°C, the shaker speed is 120-200rpm, and cultivate for 24-48 hours to obtain the shake flask strain.

[0039] The composition of the shake flask seed medium (g / L): waste oil, 30-40: NaNO 3 , 2~4; NaCl, 0.5~1.5; KCl, 0.5~1.5; CaCl 2 2H 2 O, 0.05~0.2; KH 2 PO 4 , 2~4; Na 2 HPO 4 12H 2 O, 2~4; MgSO 4 , 0.1~0.3; trace elements, 1.5~2.5mL / L, the balance is water.

[0040] Trace element composition (g / L): FeCl 3 ·6H 2 O 0.01~0.08, ZnSO 4 ·7H 2 O 0.1~0.75, CuSO 4 ·5H 2 O 0.01~0.075, MnSO 4 ·H 2 O 0.1~0.75, H 3 BO 3 , 0.01 ~ 0.15, the balance is water.

[0041] 2. Fermentation: Inoculate the shake flask strains into a fermenter of 10L or an integer multiple thereof, and cultivate with a fermentation medium, the inoculum amount is 3...

Embodiment 1

[0055] Embodiment 1: the preparation of debacterial rhamnolipid

[0056] 1. Strain: the fermentation strain is Pseudomonas aeruginosa ZJU-211 (Pseudomonas aeruginosaZJU-211)

[0057] 2. The strain was inoculated in the seed medium at a temperature of 35° C., the rotation speed of the shaker was 180 rpm, and cultured for 48 hours to obtain the shake flask strain.

[0058] The composition of the seed medium is as follows (g / L):

[0059] McDonald's Waste Grease, 30: NaNO 3 , 2; NaCl, 0.5; KCl, 0.5; CaCl 2 2H 2 O, 0.05; KH 2 PO 4 , 2; Na 2 HPO 4 12H 2 O,2; MgSO 4 , 0.1; trace elements, 1.5mL / L, the balance is water. The trace element composition is as follows: FeCl 3 ·6H 2 O 0.01, ZnSO 4 ·7H 2 O 0.1, CuSO 4 ·5H 2 O 0.01, MnSO 4 ·H 2 O 0.1g / L, H 3 BO 3 , 0.01, and the balance is water.

[0060] 3. Production of rhamnolipid by fermentation in 10L fermenter

[0061] The strains in the shake flask were inoculated into a 10L fermenter with an inoculum size of 5% (...

Embodiment 2

[0066] Embodiment 2: the preparation of rhamnolipid concentrate

[0067] 1. Strain: the fermentation strain is Pseudomonas aeruginosa ZJU-211 (Pseudomonas aeruginosaZJU-211)

[0068] 2. The strain was inoculated in the seed medium at a temperature of 38° C., the rotation speed of the shaker was 200 rpm, and cultured for 48 hours to obtain the shake flask strain.

[0069] The composition of the seed medium is as follows:

[0070] Rapeseed oil processing leftovers, 40g / L: NaNO 3 , 4g / L; NaCl, 1.5g / L; KCl, 1.5g / L; CaCl 2 2H 2 O, 0.2g / L; KH 2 PO 4 , 4g / L; Na 2 HPO 4 12H 2 O, 4g / L; MgSO 4 , 0.3g / L; trace elements, 2.5mL / L, the balance is water. The trace element composition is as follows: FeCl 3 ·6H 2 O 0.08g / L, ZnSO 4 ·7H 2 O 0.75g / L, CuSO 4 ·5H 2 O 0.075g / L, MnSO 4 ·H 2 O 0.75g / L, H 3 BO 3 , 0.15g / L, and the balance is water.

[0071] 3. Production of rhamnolipid by fermentation in 50L fermenter

[0072] Inoculate the shake flask strain into a 50L fermenter,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com