Handheld threading structure

A threading and handle technology, applied in the direction of handle connection, wing handle, building structure, etc., can solve the problems of wire breakage, product can not be used normally, wire pull out, etc., to achieve convenient assembly, ensure appearance integrity, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention can be implemented in the following ways:

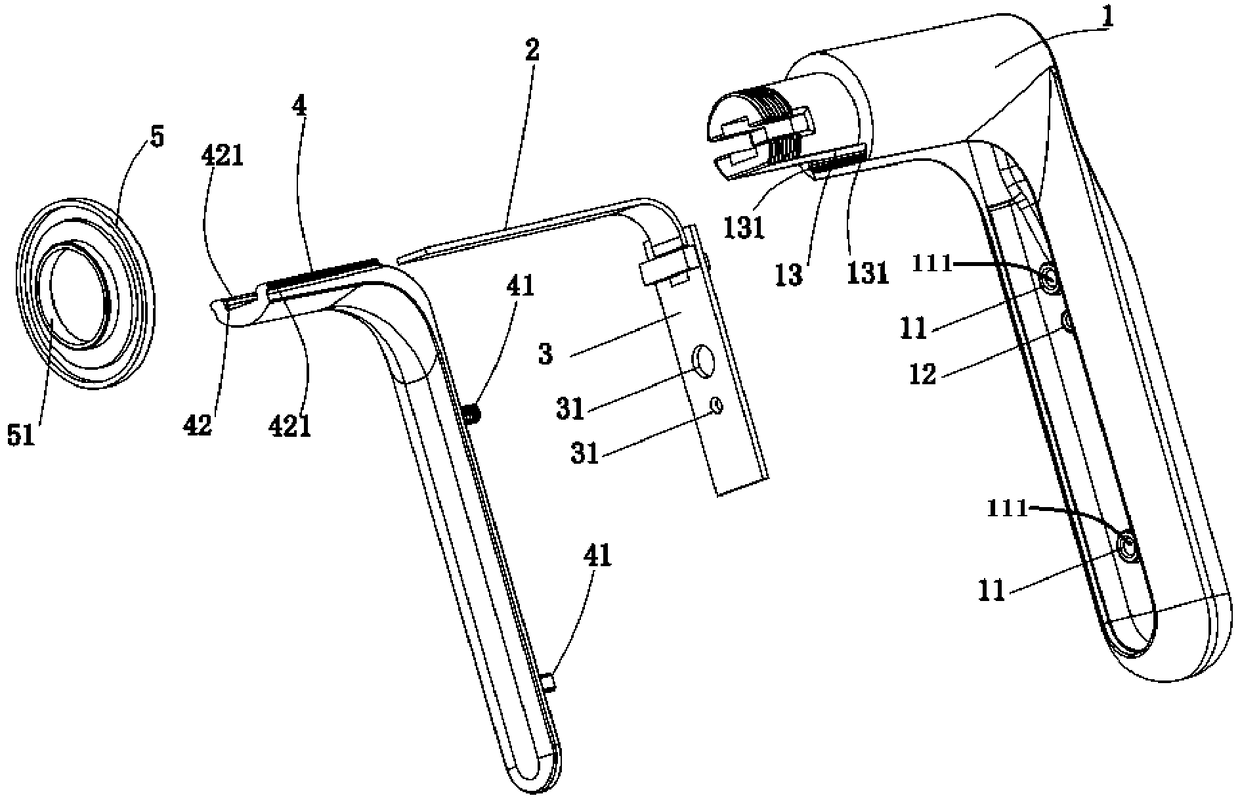

[0015] Such as figure 1 As shown: the present invention is composed of a handle 1, a wire 2, a PCB board 3, a handle cover 4 and a cover 5.

[0016] The handle part of the handle 1 is provided with two fitting posts 11 and a positioning post 12, a fitting hole 111 is provided in the center of the fitting post 11, a U-shaped groove A13 is arranged at the upper end of the handle 1, and a U-shaped groove A13 is arranged at the upper end of the handle 1. The two sides of the slot A13 are respectively provided with positioning slots 131 .

[0017] The lower end of the handle cover 4 is provided with two half screw posts 41, the front end of the handle cover 4 is provided with a U-shaped groove B42, and positioning ribs 421 are respectively provided on both sides of the U-shaped groove B42.

[0018] The PCB board 3 is provided with two positioning holes 31 .

[0019] A circular hole 51 is provided at the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com