Feeding-in tool specialized for well completion packer plug

A technology for feeding tools and plugs, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc., which can solve the problems of high time cost, slow downhole speed, and limited force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the content, features and effects of the present invention, the following examples are given to describe the present invention in detail with reference to the accompanying drawings.

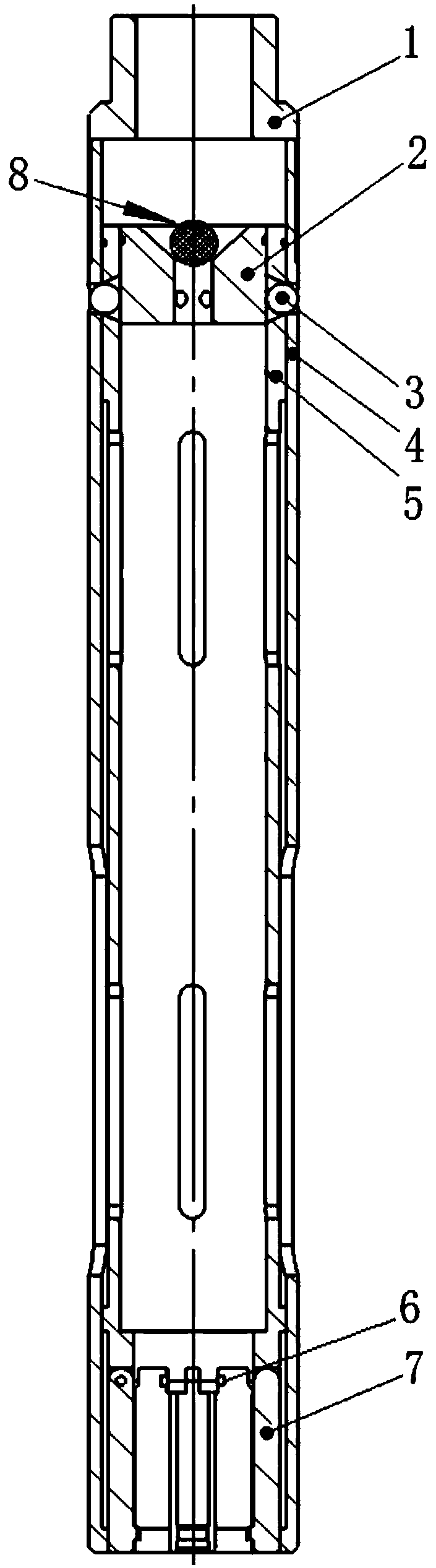

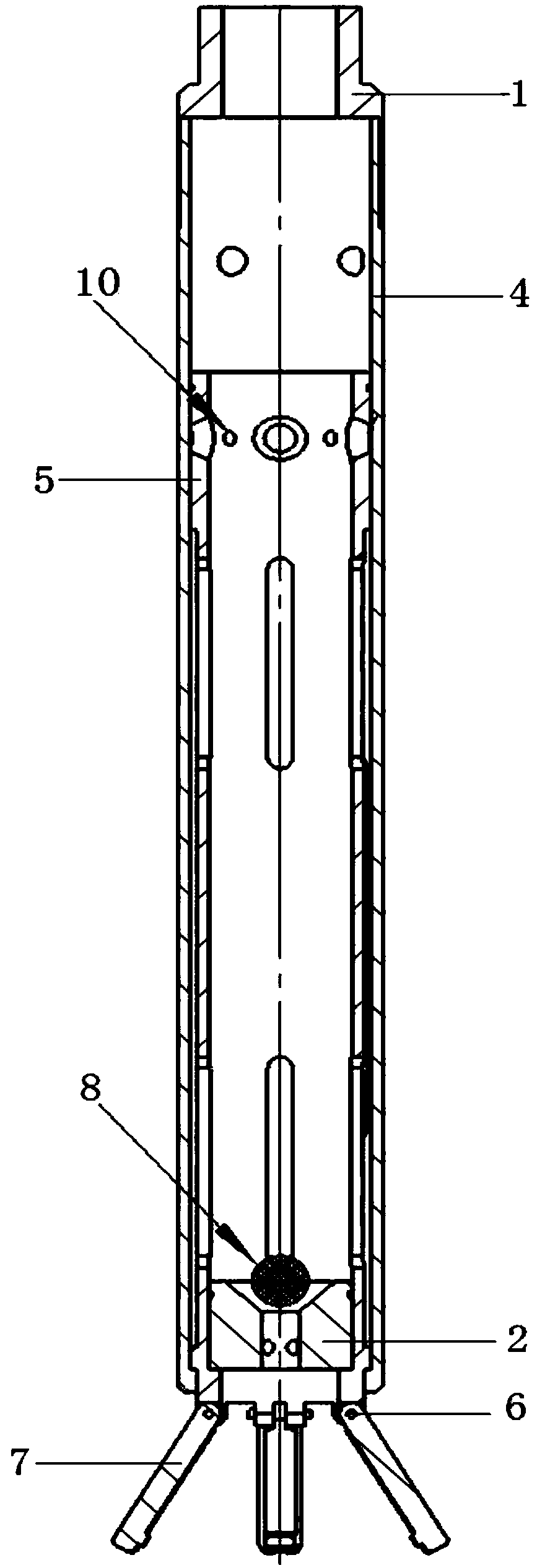

[0034] The special feeding tool for the completion packer plug of the present invention, such as Figure 1 to Figure 10 As shown, it is composed of an inner, middle and outer three-layer structure. The outer layer includes an upper joint 1 and an outer sleeve 4 connected to each other, the middle layer includes a connecting barrel 5 and a positioning claw 7, and the inner layer includes a ball seat 2.

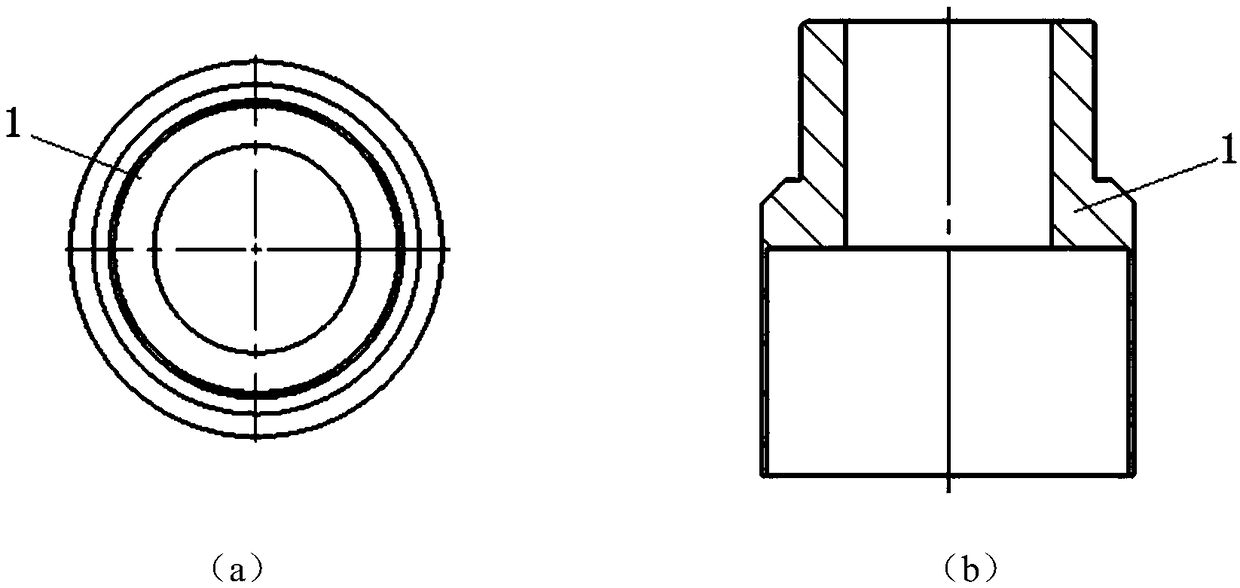

[0035] The upper joint 1 is mainly used to connect the tubing string and the outer sleeve 4. The upper end of the upper joint 1 is provided with internal threads for connecting with the tubing string during operation, the lower end is provided with internal threads, and the upper end of the outer sleeve 4 is provided with external threads for threaded connection wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com