Characterization pressure change mould box

A characterization and mold box technology, applied in the direction of measuring devices, instruments, measuring force, etc., can solve the problems of increased production and maintenance costs, wire connection analog signals are susceptible to interference, jumps and deviations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

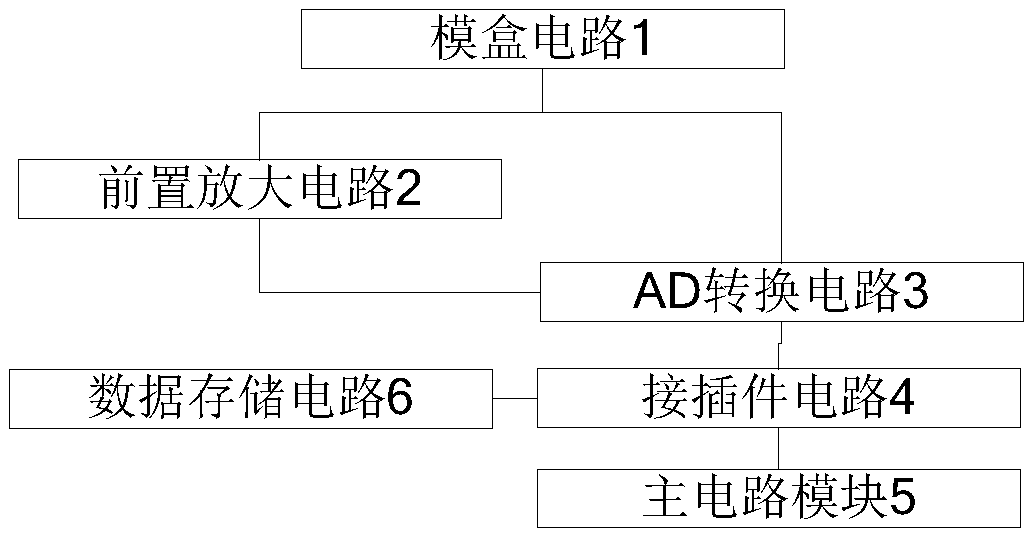

[0028] The embodiment is basically as attached figure 1 Shown:

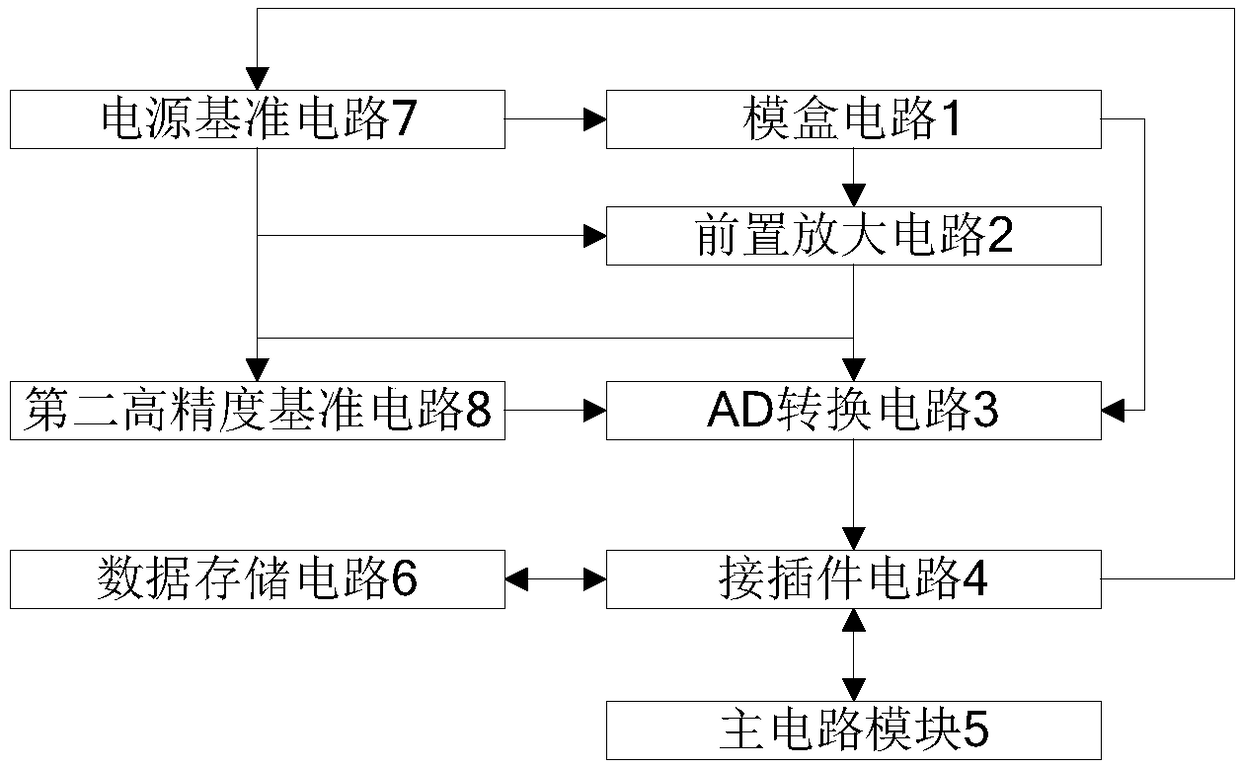

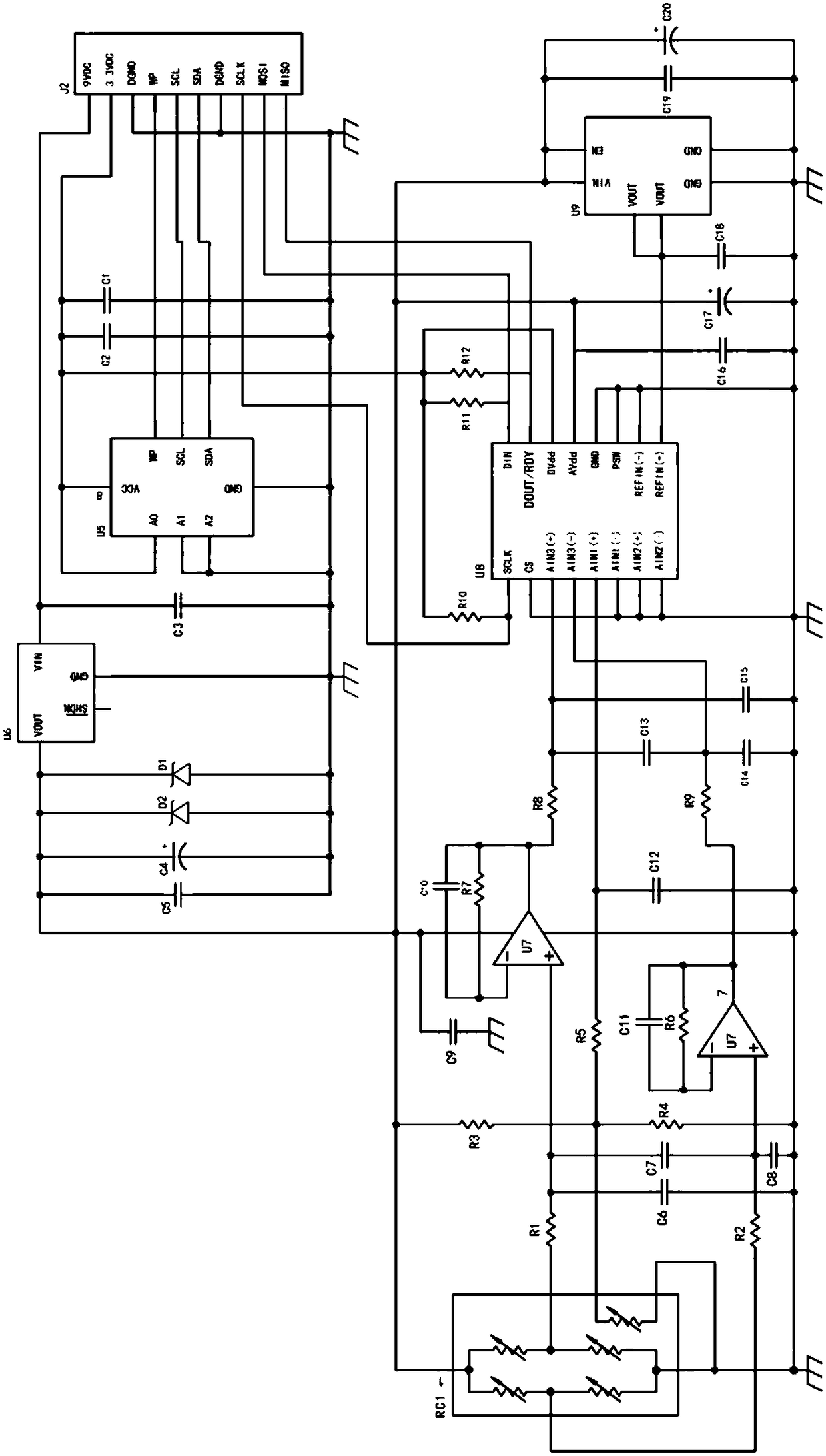

[0029] In the present embodiment, the characterized voltage-changing mold box includes: a main circuit module 5, a mold box circuit 1, a connector circuit 4, a preamplifier circuit 2, an AD conversion circuit 3 and a data storage circuit 6, and the mold box circuit 1 is used for Obtain the initial analog pressure signal and output it to the preamplifier circuit 2. The initial analog pressure signal in this embodiment is a differential analog millivolt signal. The module circuit 1 is also used to obtain the analog temperature signal and output it to the AD conversion circuit 3. The amplifying circuit 2 is used to amplify the initial analog pressure sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com