Onboard chassis with line-free design structure

A technology for designing structure and chassis, applied in the direction of chassis/cabinet/drawer parts, electrical equipment shell/cabinet/drawer, electrical components, etc. Line and maintenance, saving back space, and meeting the effect of vibration and shock requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

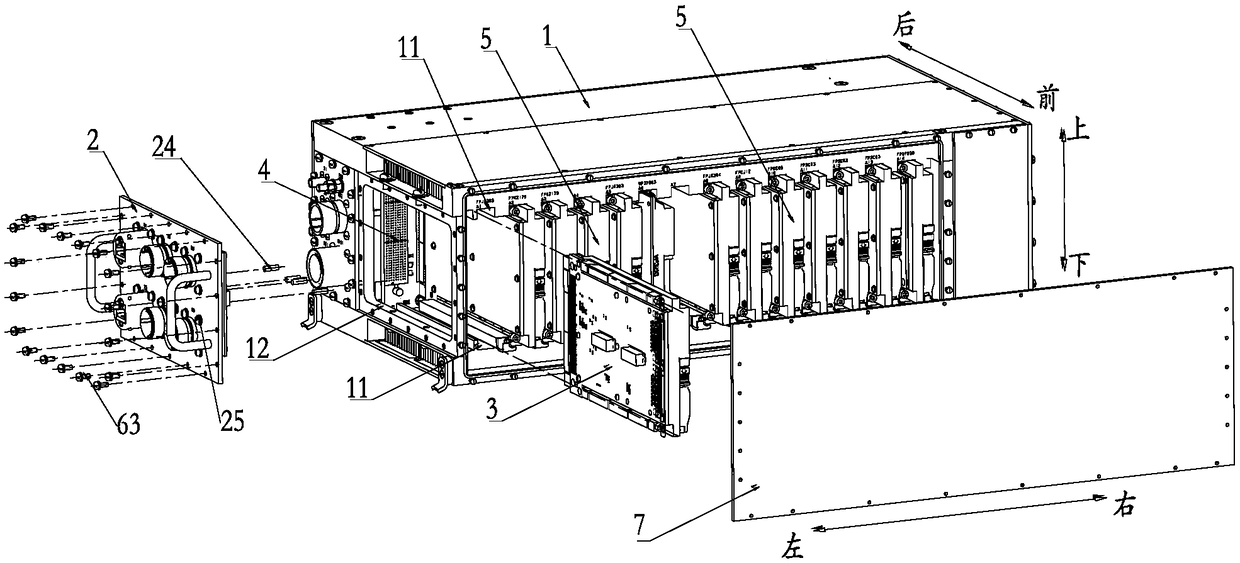

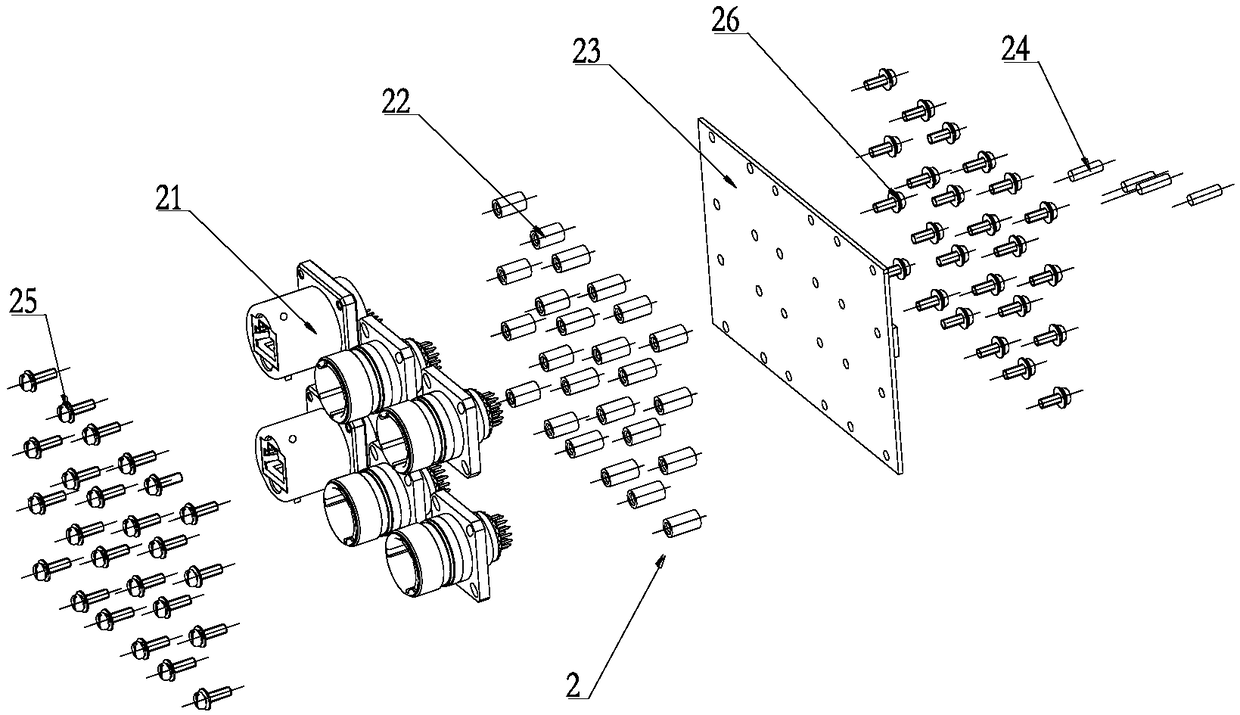

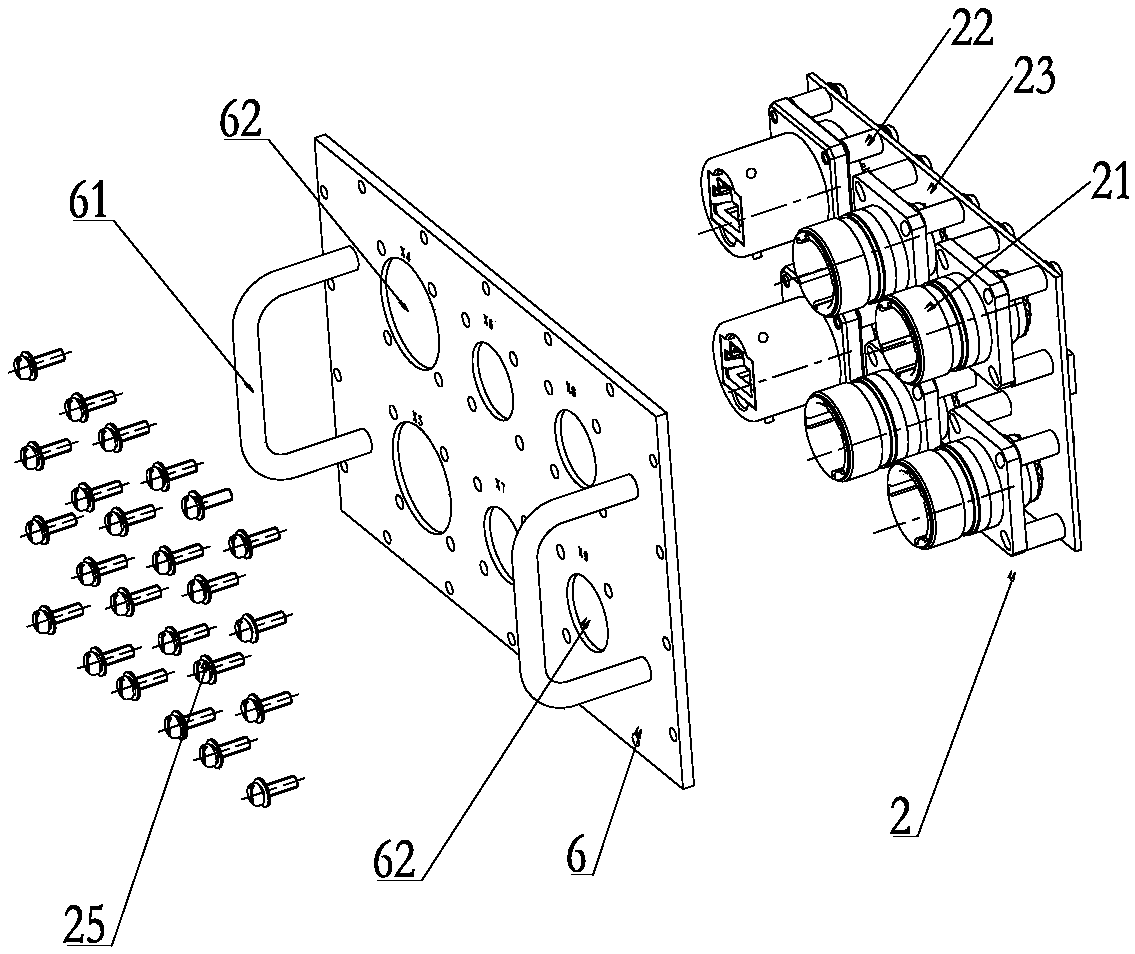

[0039] Such as Figure 1-Figure 5 As shown, an airborne chassis with a wire-free design structure in this embodiment includes an electronic chassis 1, an IO connector assembly 2, and a connector plug-in 3. A plug-in motherboard 4, a number of electronic Plug-in 5 and some electronic devices, some of the electronic plug-ins 5 are connected to the front side of the plug-in motherboard 4, and some of the electronic devices are connected to the rear side of the plug-in motherboard 4, and the IO connector assembly 2 is installed At one end of the electronic chassis 1; a slot 11 is reserved near the end of the IO connector assembly 2 in the electronic chassis 1, and the plug-in motherboard 4 and the IO connector assembly 2 are all connected to the slot The position 11 is connected, and the connector insert 3 is plugged into the slot 11 and connected with the IO connector assembly 2 and the insert motherboard 4 respectively to realize signal transfer.

[0040] In this embodiment, th...

Embodiment 2

[0043] Such as Figure 1-Figure 5As shown, an airborne chassis with a wire-free design structure in this embodiment includes an electronic chassis 1, an IO connector assembly 2, and a connector plug-in 3. A plug-in motherboard 4, a number of electronic Plug-in 5 and some electronic devices, some of the electronic plug-ins 5 are connected to the front side of the plug-in motherboard 4, and some of the electronic devices are connected to the rear side of the plug-in motherboard 4, and the IO connector assembly 2 is installed At one end of the electronic chassis 1; a slot 11 is reserved near the end of the IO connector assembly 2 in the electronic chassis 1, and the plug-in motherboard 4 and the IO connector assembly 2 are all connected to the groove. The position 11 is connected, and the connector insert 3 is plugged into the slot 11 and connected with the IO connector assembly 2 and the insert motherboard 4 respectively to realize signal transfer. Among them, the connector plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com