Automatic pineapple picking collection device

A technology of collecting device and pineapple, which is applied in the fields of harvester, agriculture, application, etc., can solve the problems of low production efficiency and high labor intensity, and achieve the effect of compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] Automatic pineapple picking collecting device of the present invention, its preferred embodiment is:

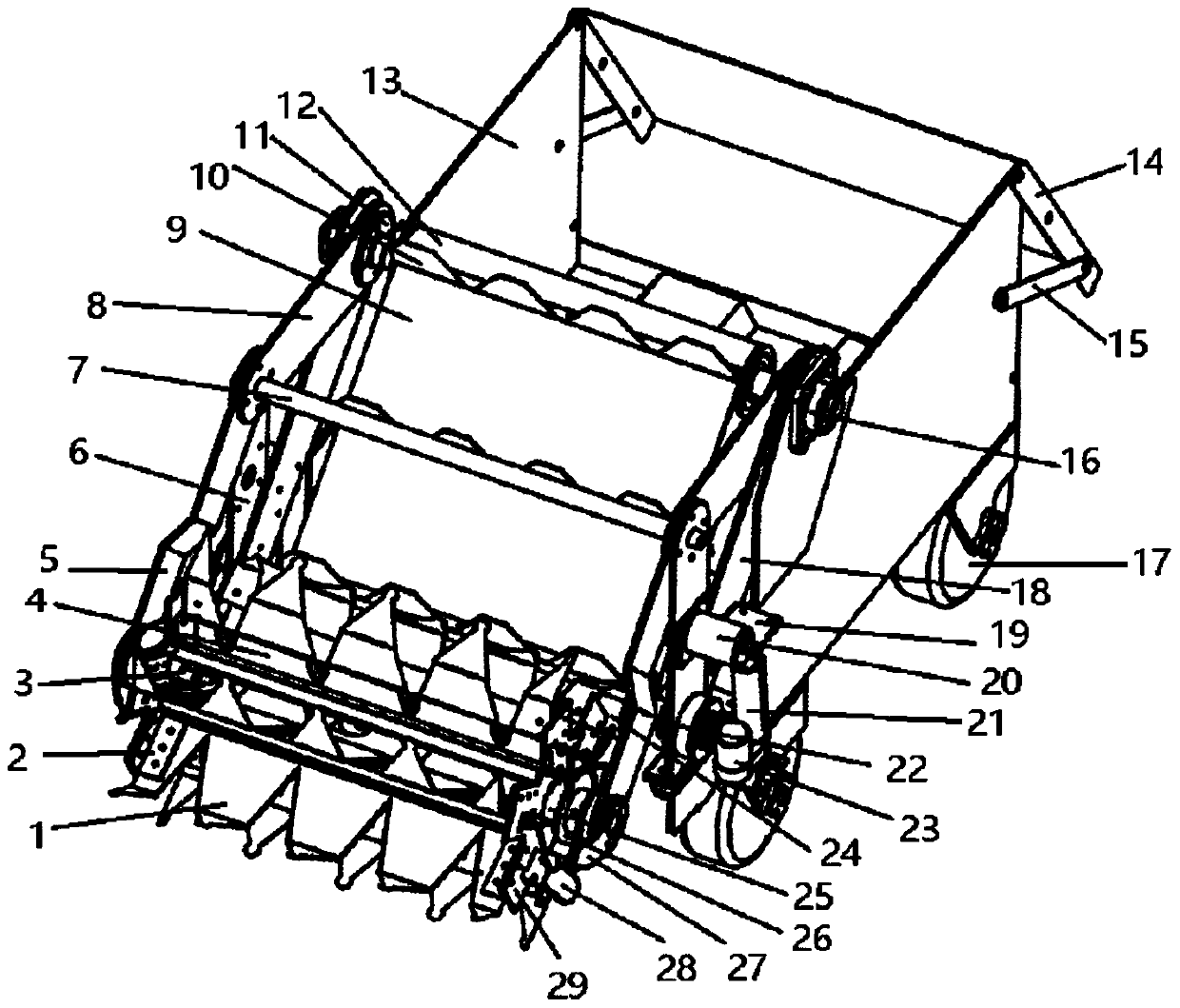

[0019] Including picking parts, transporting parts, lifting parts, power transmission parts, storage parts;

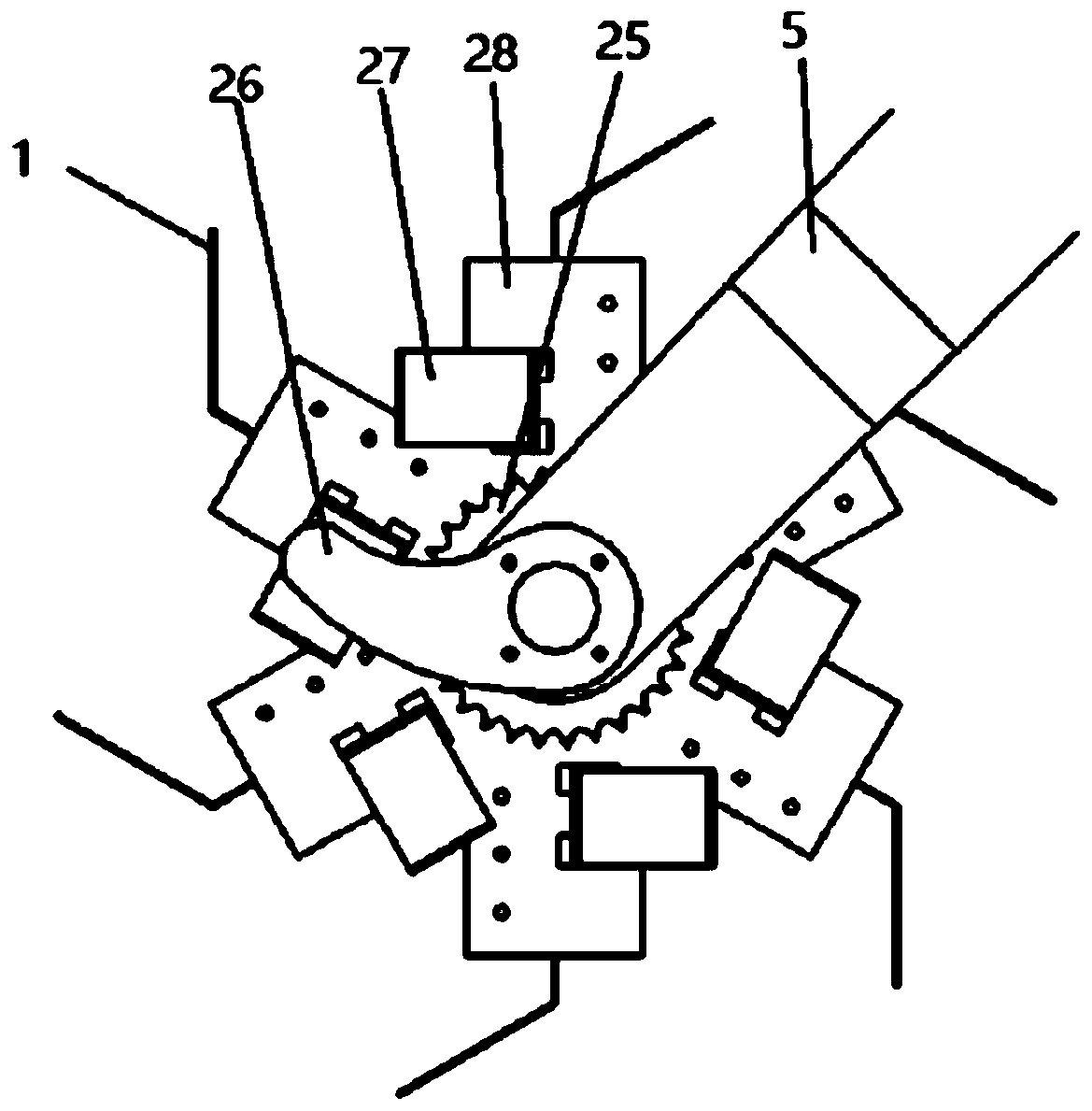

[0020] The picking component is installed on the front end of the knife holder support plate, including the main blade, L-shaped connector, rotating shaft, shear blade, knife holder seat, paddle, baffle plate, sprocket wheel group, and knife holder flange;

[0021] The conveying parts are installed on the frame support plate and the vehicle body, including PVC conveyor belt, conveyor partition, conveyor roller, conveyor drive shaft, and frame flange;

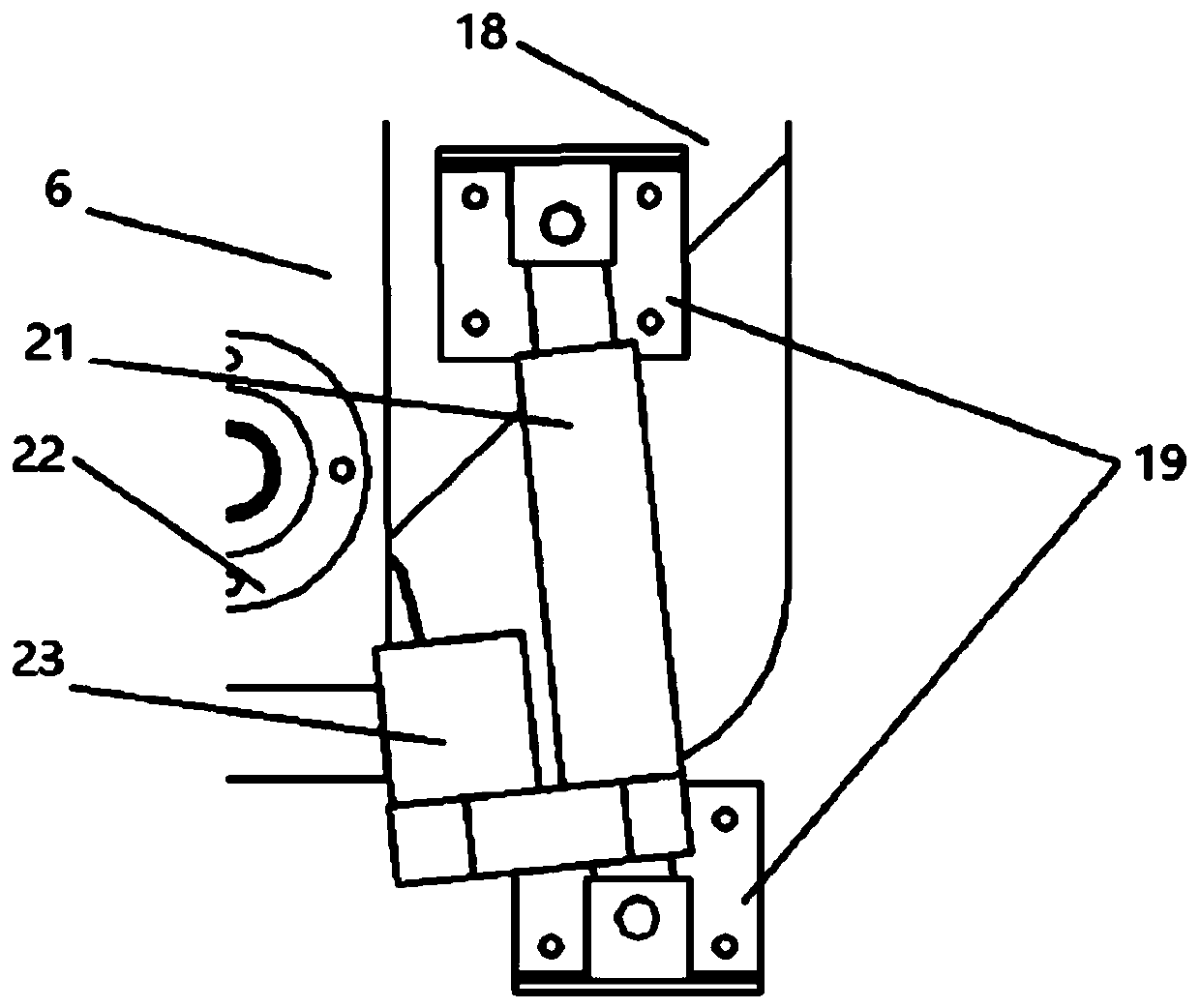

[0022] The lifting component includes an electric push rod mounting seat and an electric push rod, and the electric push rod connects the rack slant plate and the vehicle body through the mounting seat;

[0023] The power transmission components include a DC motor, a motor governor, a sprocket set and a matching...

specific Embodiment

[0036] Specific examples: such as figure 1 As shown, the present invention includes picking parts, transportation parts, lifting parts, power transmission parts, storage parts. Wherein the picking parts are installed on the front end of the knife rest support plate 5, including main blade 1, L-shaped connector 2, knife rest rotating shaft 3, shear blade 4, knife rest seat 29, plectrum 28, baffle plate 26, sprocket wheel group 26. Tool holder flange 25. The transport components are installed on the frame support plate 6 and the vehicle body 13, including a PVC conveyor belt 9, a conveyor partition 10, a conveyor roller 12, and a conveyor drive shaft 24. The lifting components include an electric push rod mounting seat 19 and an electric push rod 21 , and the electric push rod 21 is connected to the frame slant plate 18 and the vehicle body 13 through the mounting seat 19 . The power transmission components include sprocket set 26 and associated chain. The storage components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com