An automated sugarcane harvester

A harvester, sugarcane technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of inflexibility, complicated work, large losses, etc., and achieve the effect of reducing volume, reducing labor intensity, and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

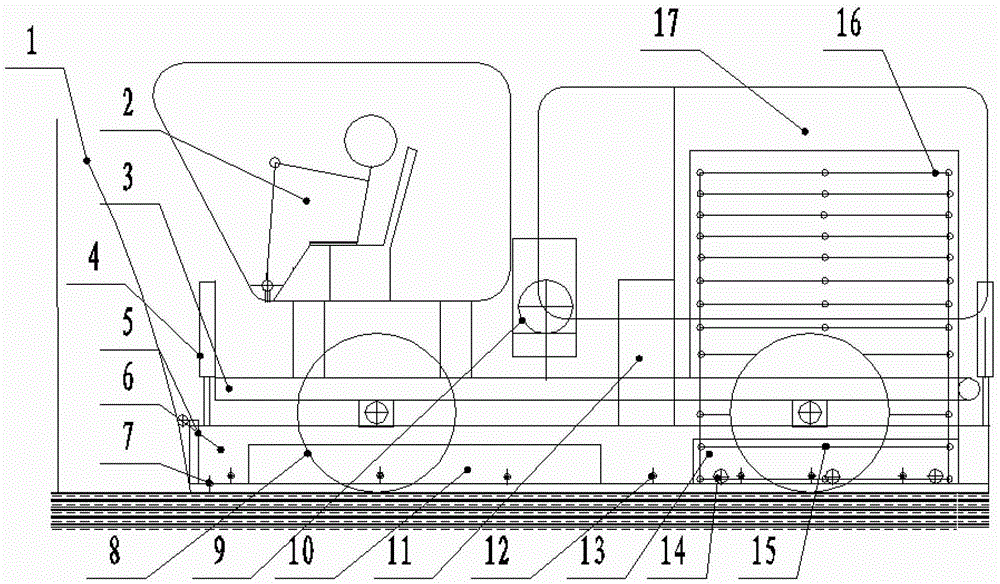

[0018] A preferred embodiment of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 Shown:

[0020] An automatic sugarcane harvester, comprising a walking frame 3, walking wheels 8 on both sides of the walking frame 3, a power source 9 and a cab 2 above the walking frame 3, the bottom of the walking frame 3 is provided with a comprehensive harvesting chamber 6, The front end of the comprehensive harvesting chamber 6 is fixed to cut the sugarcane saw 5 for cutting off the sugarcane 1, and the comprehensive harvesting chamber 6 is provided with a cane guide wheel 7 for transporting the cut sugarcane 1 backwards, and a detachment for removing the sugarcane leaves from front to back in the comprehensive harvesting chamber 6. Leaf mechanism 10, leaf-removing cane guide 12, leaf-removing cane transition chamber 13, hinge cage propeller 14 and sugarcane lifter 15, above the sugarcane lifter 15 is a sugarcane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com