Inserting and cutting type banana combing device capable of surrounding banana stems in self-adaptive manner

An adaptive, banana technology, applied in application, food processing, food science and other directions, can solve the problems of high labor intensity, dangerous banana surface machinery, low operation efficiency, etc., to reduce the number of operators, reduce manual physical consumption, reduce The effect of manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific examples.

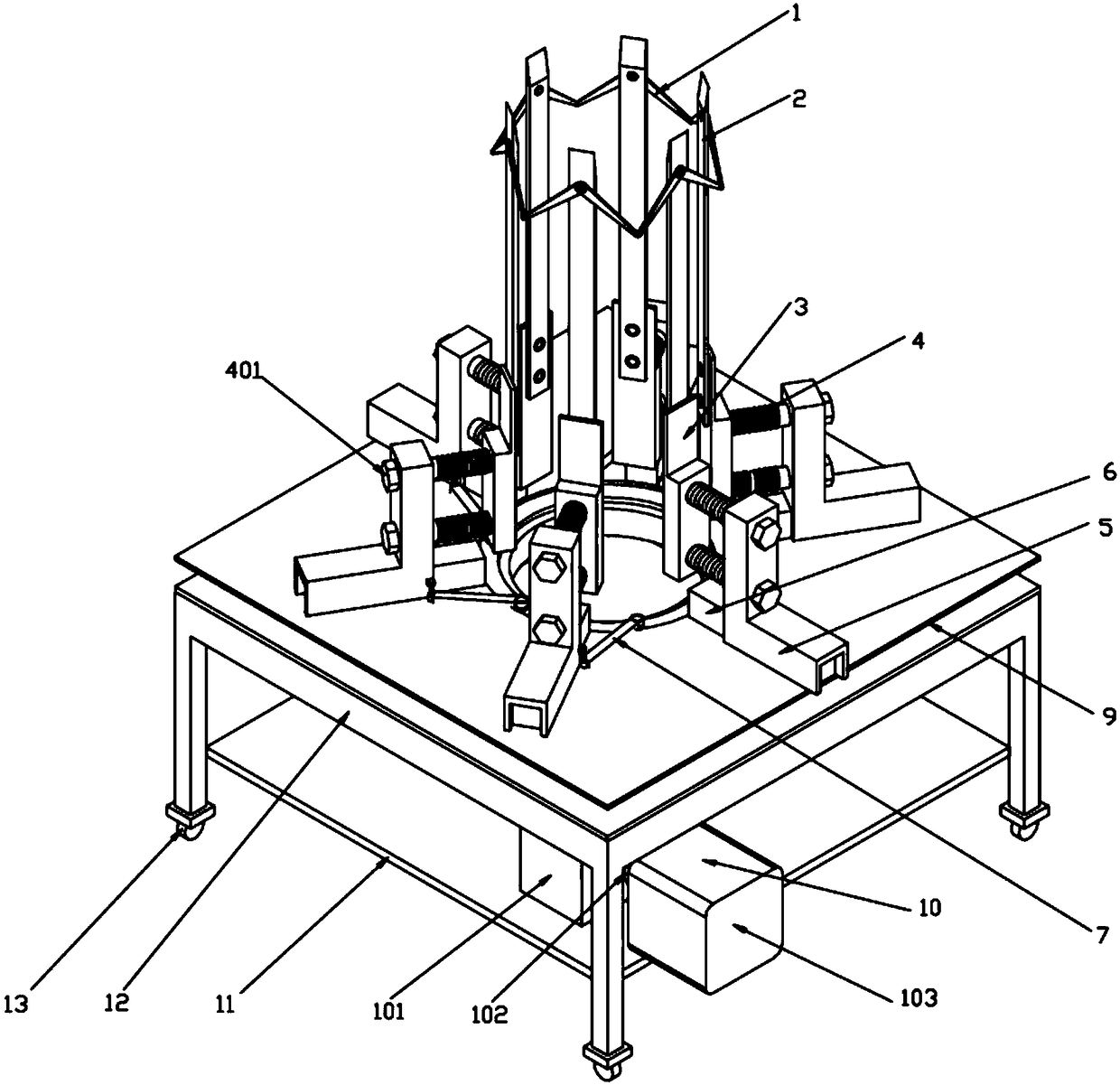

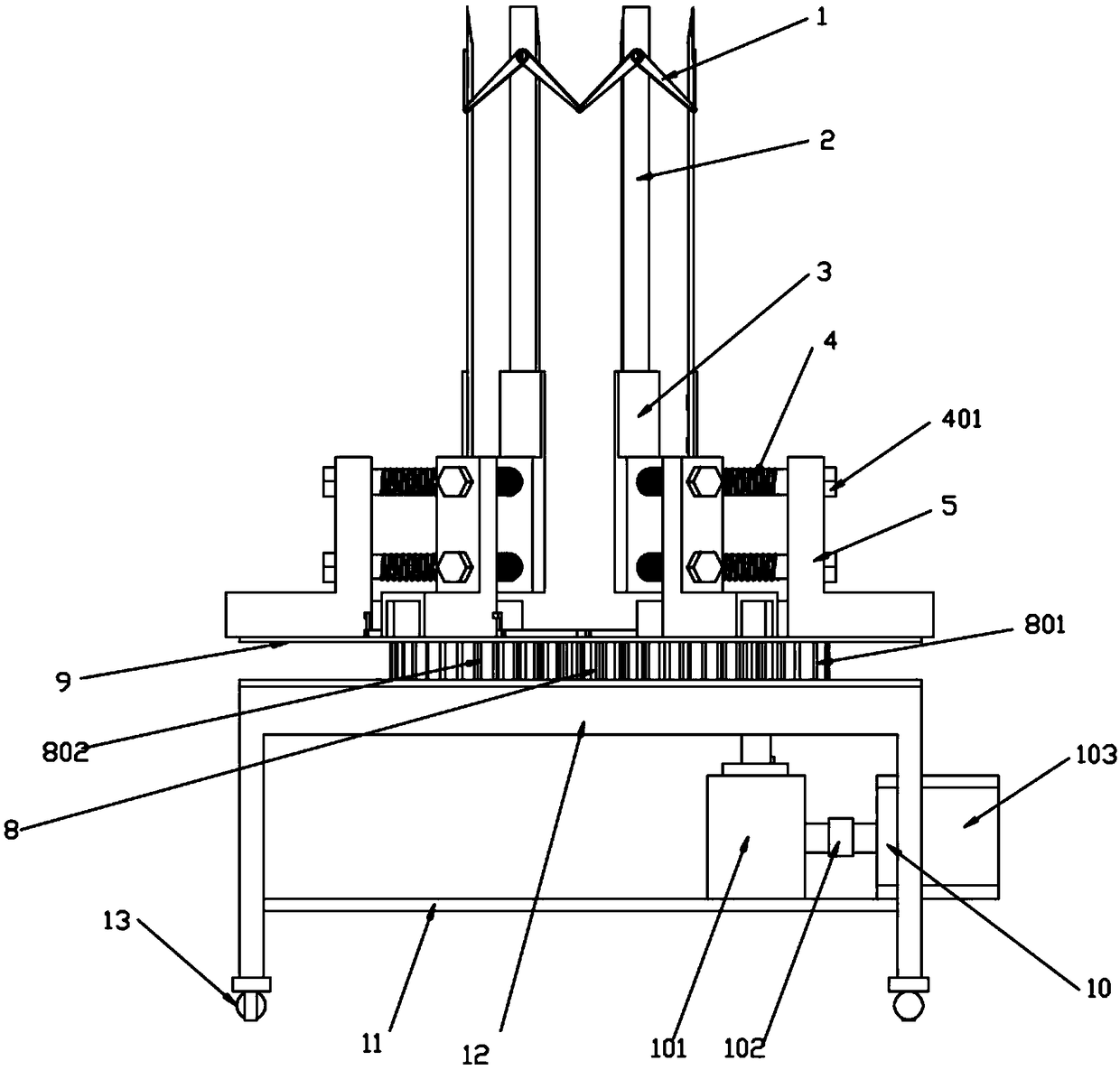

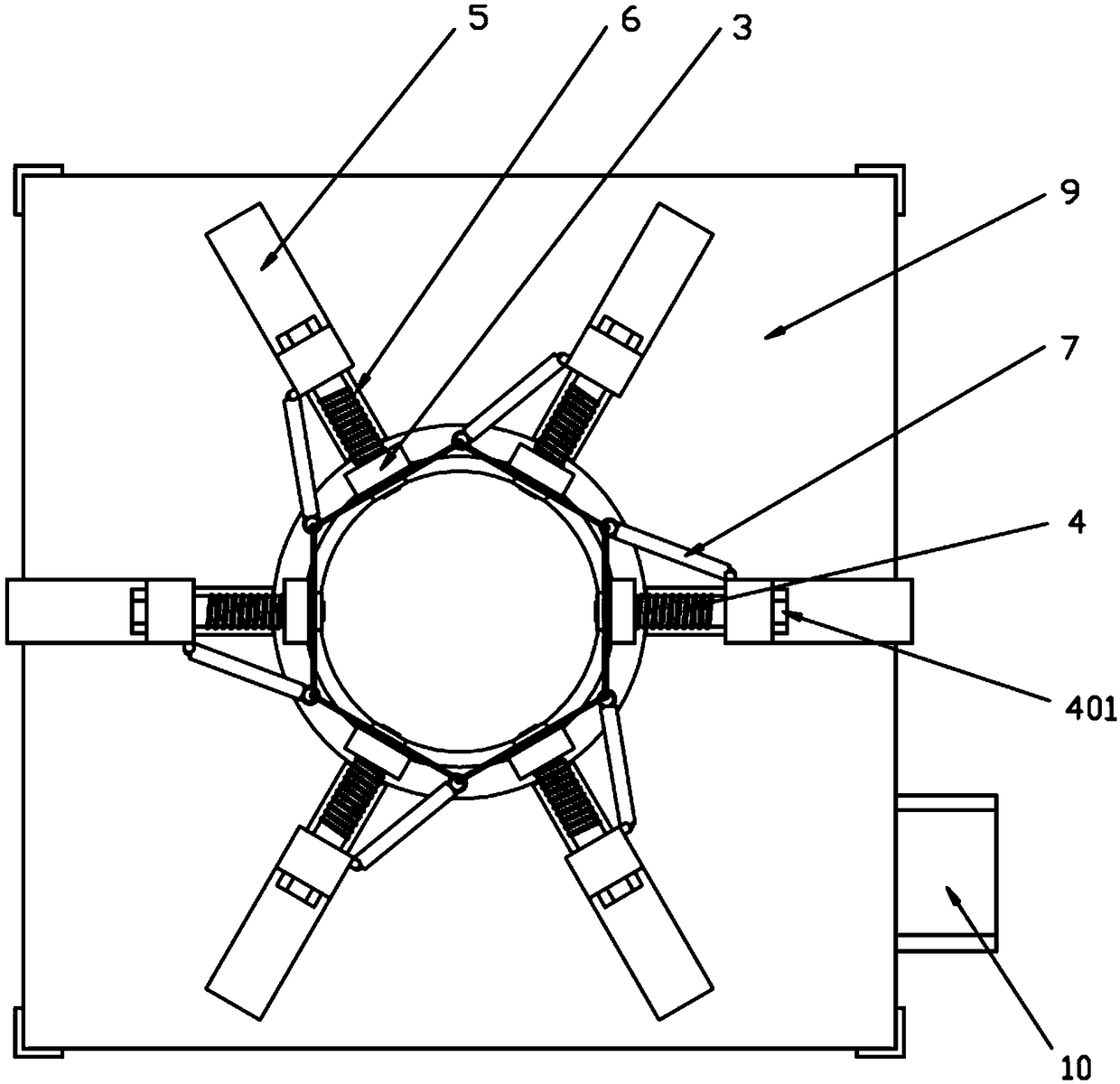

[0017] see Figure 1 to Figure 3 As shown, the plug-and-cut banana combing device that can adaptively surround the banana stem provided by this embodiment is mainly used for mechanized banana combing, including frame 12, power source 10, cutter head 9, gear set 8, connecting Rod 7, linear guide rail 6, L-shaped slide block 5, spring 4, hard blade mounting frame 3, hard blade 2, soft blade 1; Described gear group 8 is installed on the table top of frame 12, is driven by driving gear 801 meshing with the driven gear 802, the driving gear 801 is driven to rotate by the power source 10 installed under the table of the frame 12, the cutter head 9 is horizontally installed on the table of the frame 12 through multiple supports, and is located on Above the gear set 8, the center of the cutter head 9 has a through hole concentric with the center hole of the driven gear 802 for passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com