Moving crushing device for building waste

A technology of construction waste and crushing device, which is applied in grain processing and other fields, and can solve the problems of large equipment occupation space, physical hazards of operators, and heavy transportation of the machine body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

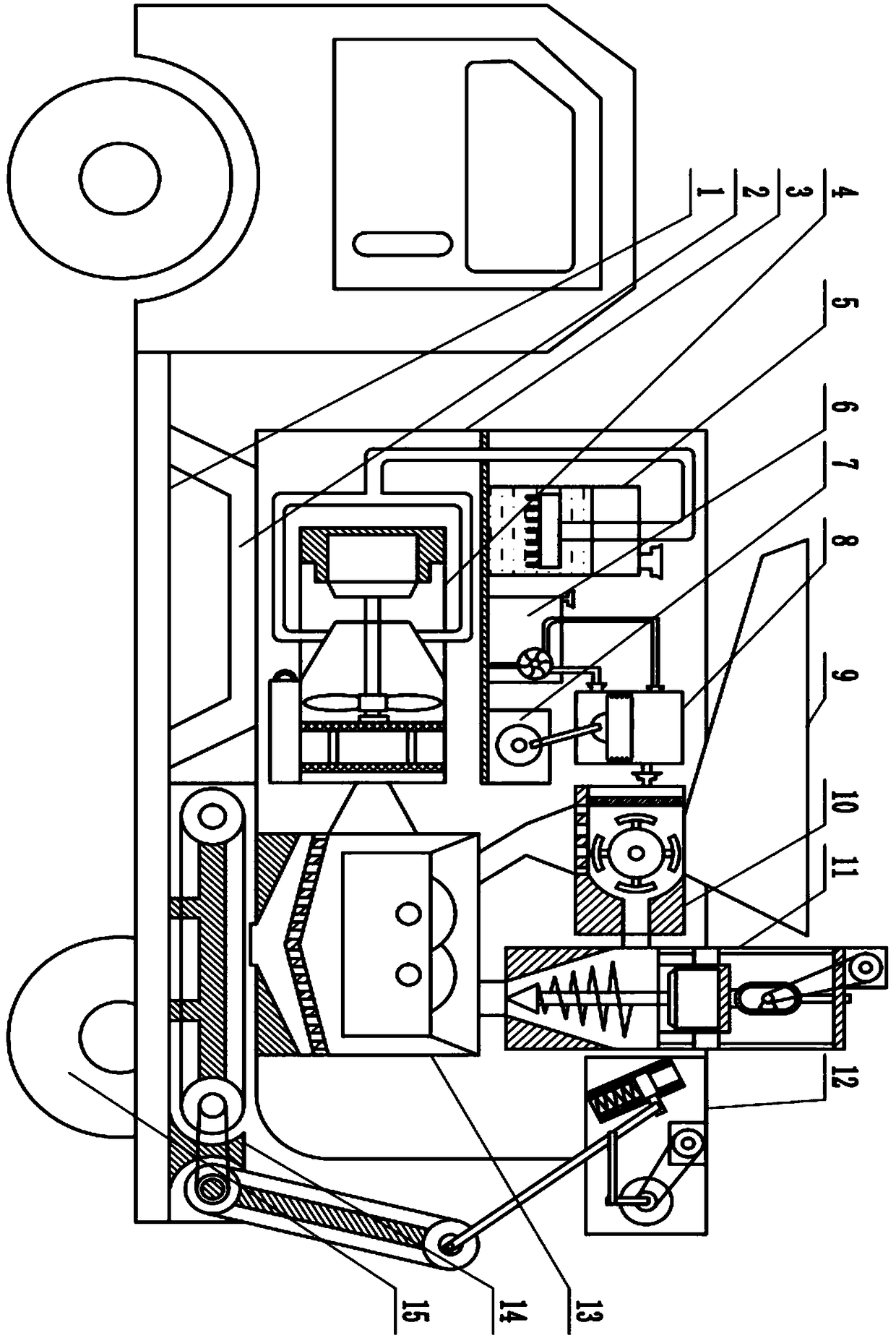

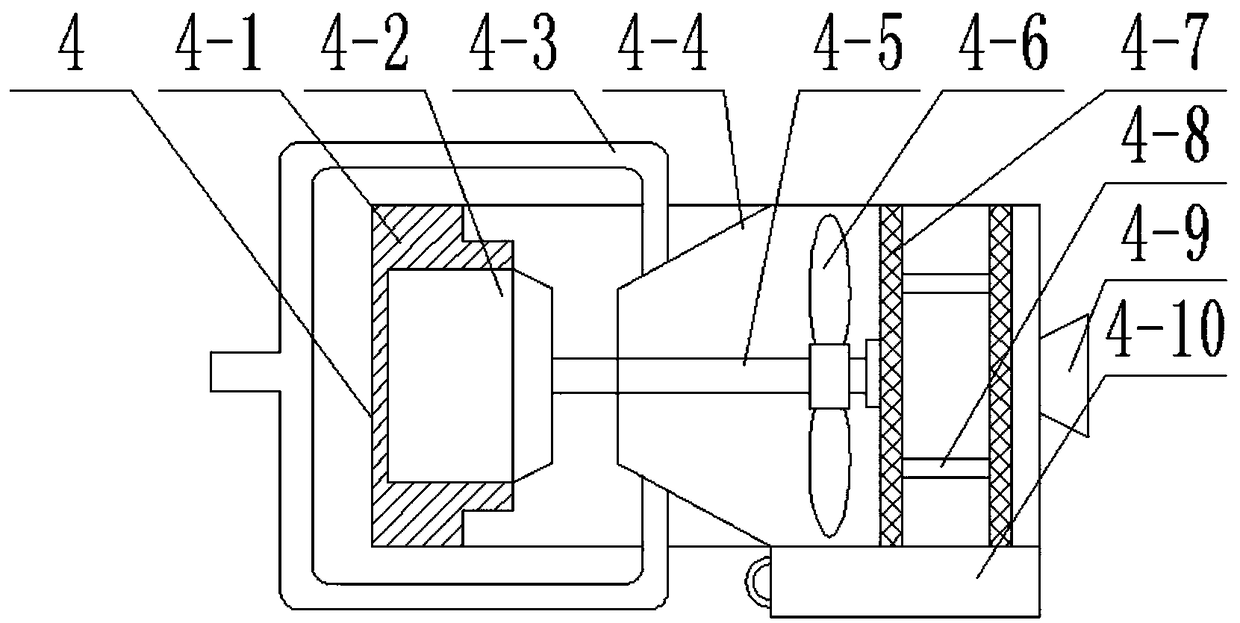

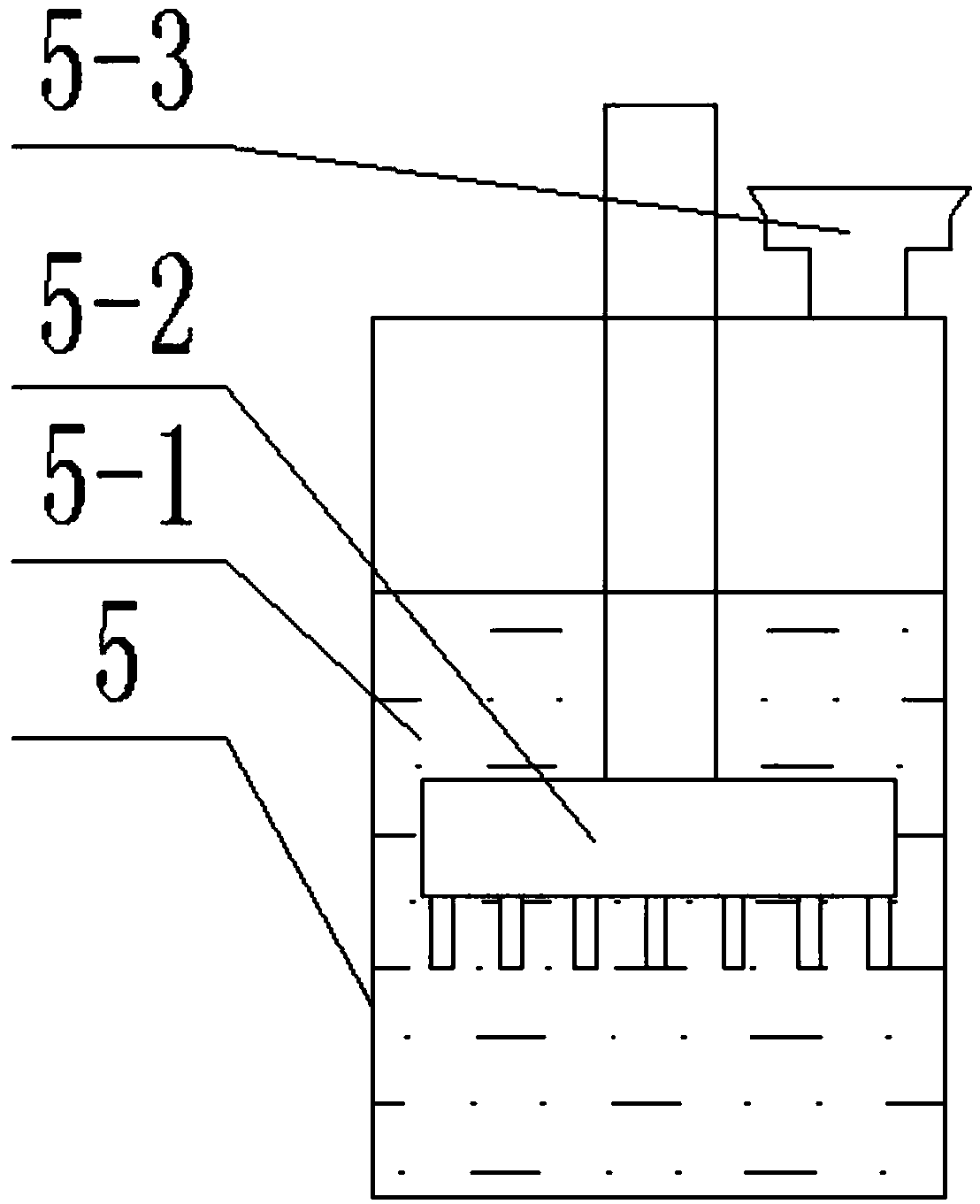

[0035] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11 illustrate this embodiment, the main technical problem to be solved by the present invention is to provide a mobile crushing device for construction waste, including a car plate 1, a box support seat 2. Box body 3. Dust ventilation device 4. Dust filter box 5. Clear water tank 6. Pumping box motor 7. Pumping box 8. Waste disposal box 9. Time difference transport box 10. Crushing box 11. Conveyor belt control box 12 , crushing box 13, conveying device 14, wheels 15, the construction waste after the demolition of old buildings is generally buried or piled up and crushed. Most of the buildings are too narrow in space and the space is too small to place the crushing device, and the body of the crushing device is too heavy to transport and it is inconvenient, and the existing crushing device will generate a lot of dust and dust when crushing construction waste , The operator inhales too much will cause harm to the bo...

specific Embodiment approach 2

[0046] Combine below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11 illustrate this embodiment, and this embodiment will further illustrate Embodiment 1. , crushing tooth rotating shaft gear 13-5, rotating roller 14-1, angle rotating roller 14-5 are all set to two.

specific Embodiment approach 3

[0047] Combine below figure 1 , 2 . Broken cone 11-5, broken box motor 11-8, ring gear 11-10 share the central line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com