Forming method and forming die for thin-walled spherical parts

A technology for spherical and parts, which is applied in the field of plastic forming of thin-walled parts, can solve the problems of low dimensional accuracy of parts, lower production efficiency, poor surface quality, etc., and achieve the effect of improving surface quality, improving production efficiency and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A method for forming a thin-walled spherical part and its auxiliary device according to the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

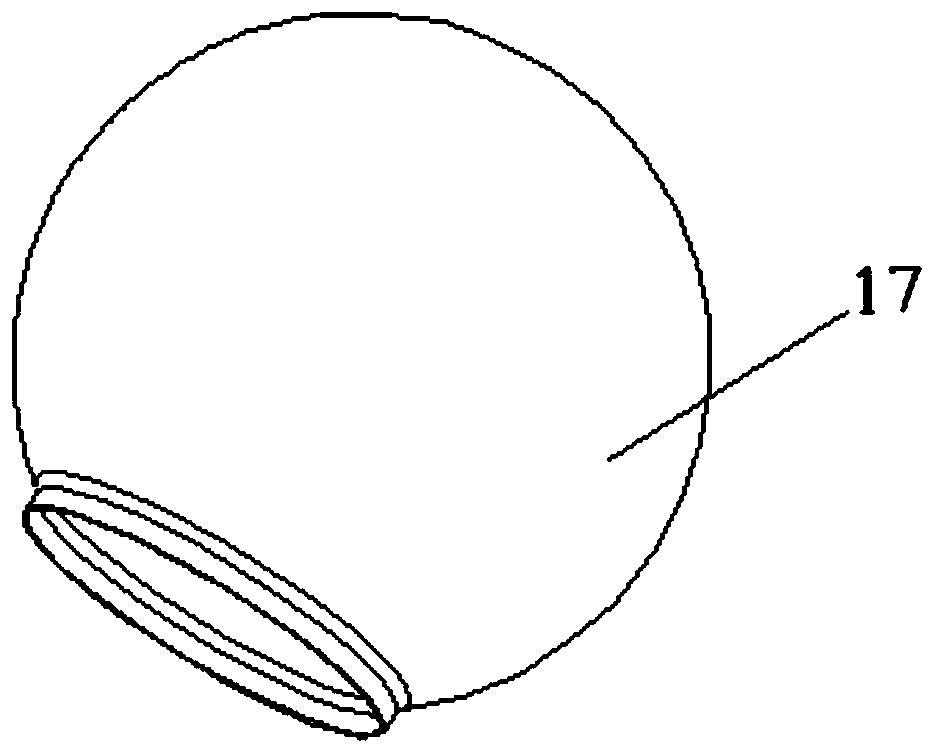

[0018] figure 1 It is a spherical part 17, and the traditional forming method needs to be formed into two hemispheres and then spliced into a spherical part. It has the disadvantages of complex forming process and low surface quality.

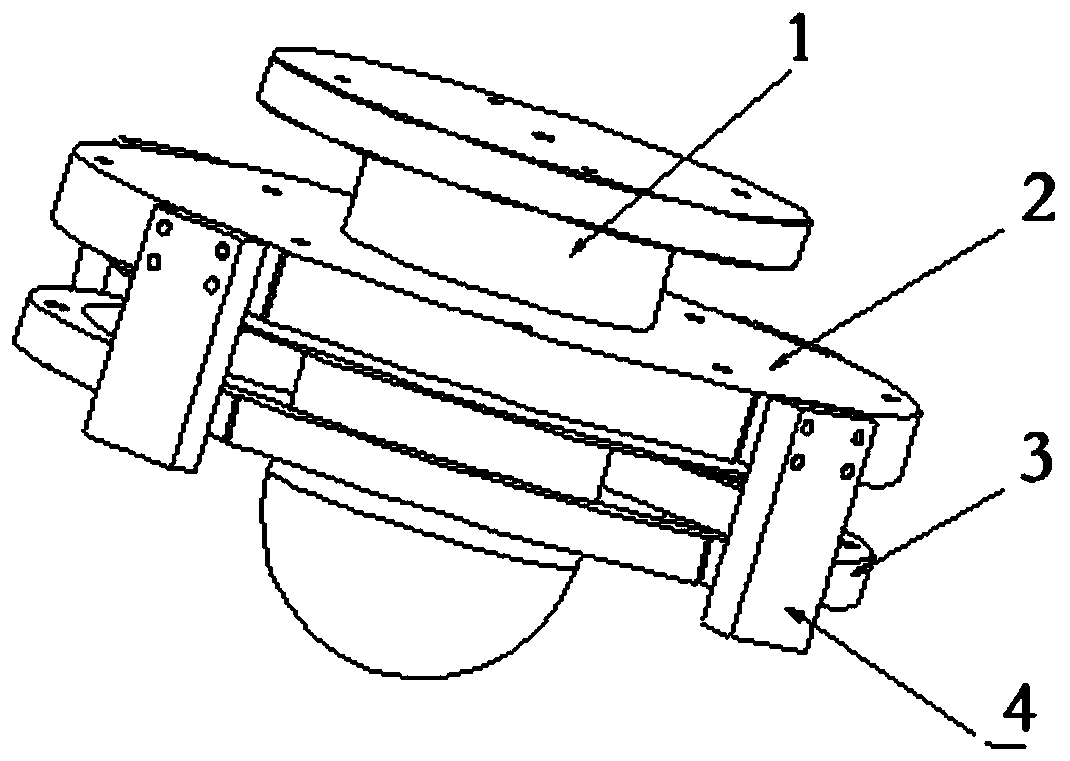

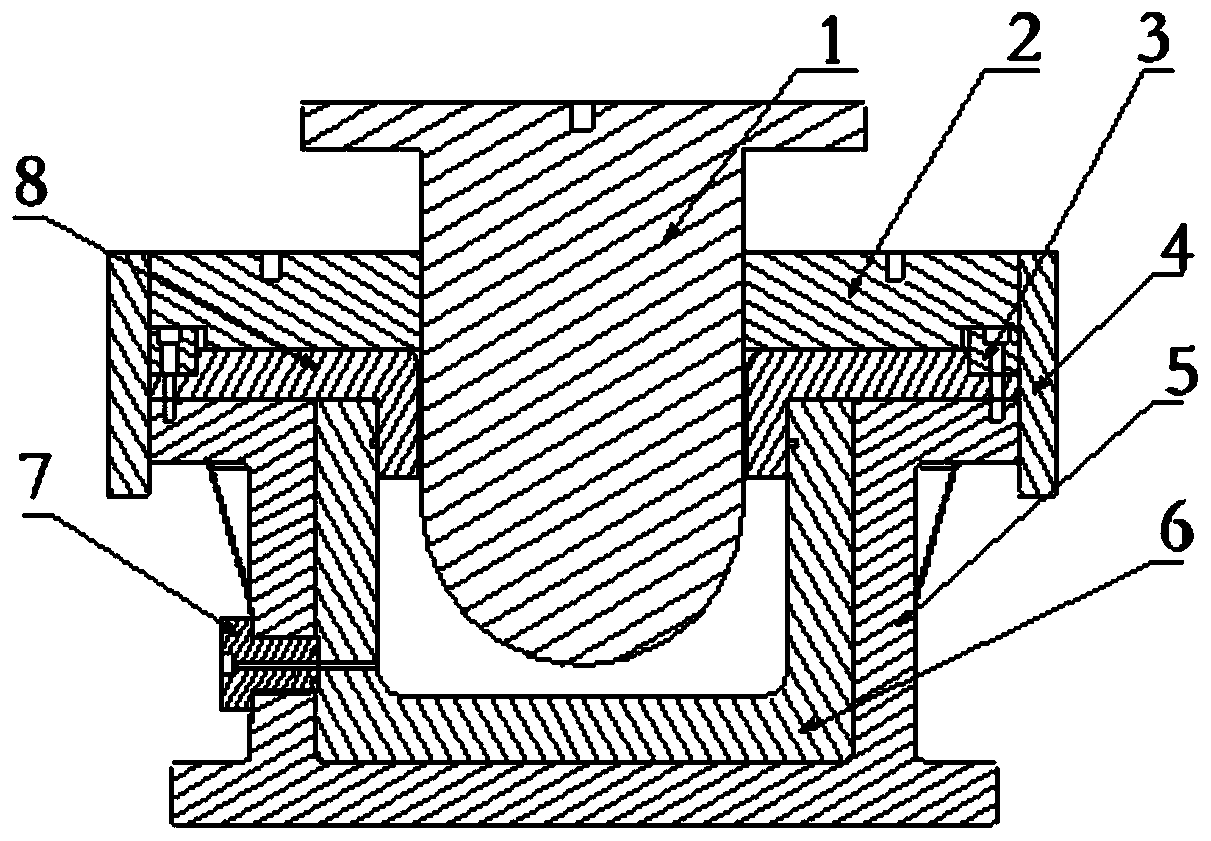

[0019] The invention provides a forming method of a thin-walled spherical part and an auxiliary forming die. The forming method includes two parts: pre-forming and final forming. Firstly, a straight-wall spherical bottom cylindrical part is formed by passive liquid-filled forming technology. After stress relief annealing, the pre-formed spherical bottom cylindrical part is placed in an internal high pressure In the bulging mold, the spherical part 17 is finally bulged.

[0020] As shown, a passive liquid-filled forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com