Flexible roll-bending forming device and method for fiber-metal super hybrid composite laminate

A roll-bending, super-hybrid technology, applied in chemical instruments and methods, lamination, and layered products, etc., can solve the problems of high mold cost, low flexibility in forming and processing, and significant springback in self-forming processes. High forming accuracy and forming quality, important engineering application value, and uniform residual stress distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

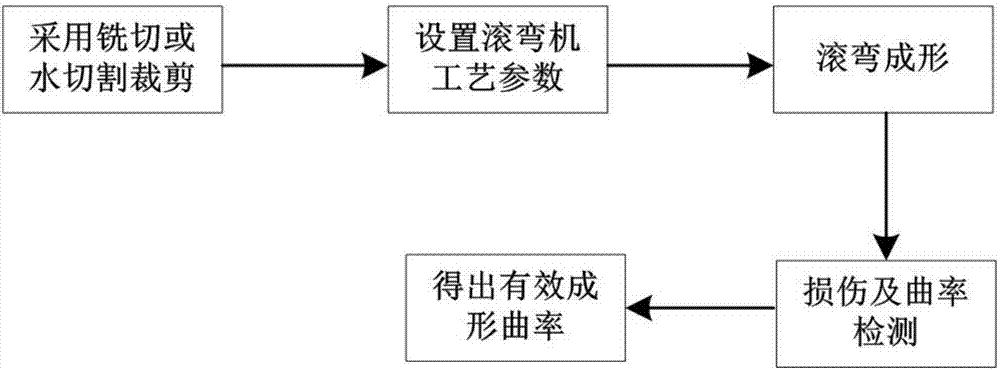

[0032] Embodiment 1: with reference to attached figure 1 A flexible roll-bending forming method for a fiber-metal super-hybrid composite laminate as shown, comprising the following steps:

[0033] The first step is to select a 3 / 2 structure with a thickness of 1.4mm and a glass fiber-aluminum alloy super-hybrid composite laminate with a fiber layup direction of 0° / 0°. The specific material components are S4 high-strength glass fiber and epoxy resin , 2024 aluminum alloy.

[0034] The second step is to cut the material to 30mm×300mm by means of CNC milling. cold.

[0035] The third step is to adjust the specific process parameters of the roll bender, and place the glass fiber-aluminum alloy super-hybrid composite laminate between the upper and lower rollers.

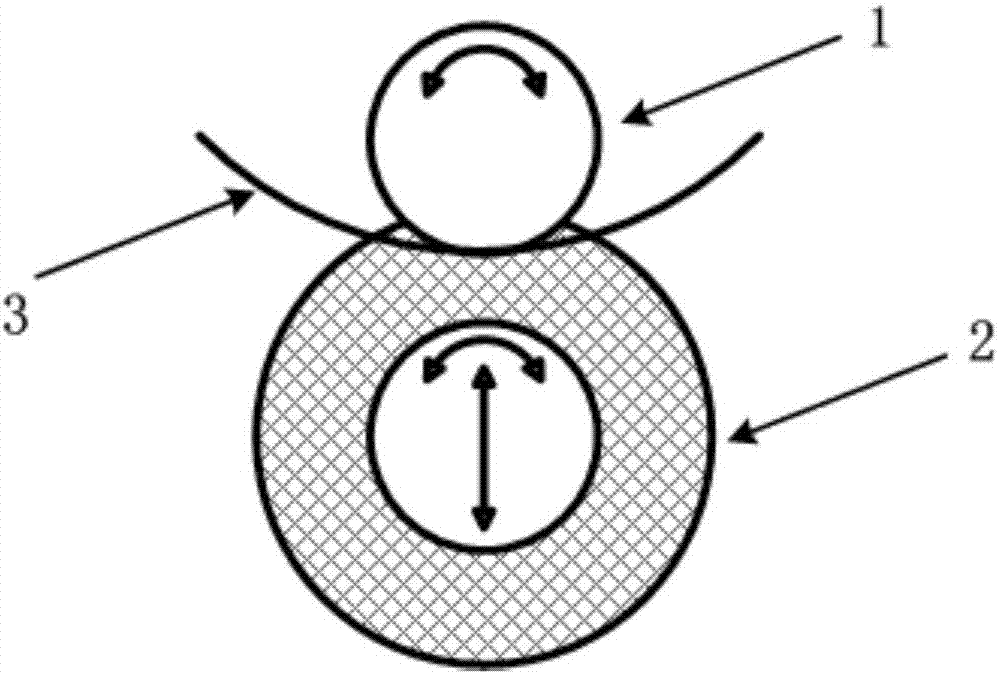

[0036] The fourth step is to select the rigid upper roller with a pressing force of 10mm and a roller speed of 2000r / min, and perform roll bending on the material. Through the combined effect of the compressive stress...

Embodiment 2

[0040] The first step is to select a 3 / 2 structure with a thickness of 1.7mm and a carbon fiber-titanium alloy hyperhybrid composite material with a fiber layup direction of 0° / 0°. The specific material components are T700 carbon fiber, polyimide resin, TC4 aluminum alloy.

[0041] In the second step, the material is cut to 30mm×300mm by CNC milling. The specific process parameters are: rotating speed 10000r / min, feed speed 1m / min, back cutting amount 0.1mm, cutting tool diameter 2mm, water cooling.

[0042] The third step is to adjust the specific process parameters of the roll bender, and place the glass fiber-aluminum alloy super-hybrid composite laminate between the upper and lower rollers.

[0043] The fourth step is to select the rigid upper roller with a press force of 8mm and a roller speed of 1000r / min, and perform roll bending on the material. Through the combined effect of the compressive stress of the rigid upper roll and the friction between the flexible medium ...

Embodiment 3

[0047] The first step is to select a 3 / 2 structure with a thickness of 1.7mm and a carbon fiber-aluminum alloy super hybrid composite material with a fiber layup direction of 0° / 0°. The specific material components are T300 carbon fiber, polypropylene resin, and 7075 aluminum alloy .

[0048] The second step is to cut the material to 30mm×300mm by water cutting.

[0049] The third step is to adjust the specific process parameters of the roll bender, and place the glass fiber-aluminum alloy super-hybrid composite laminate between the upper and lower rollers.

[0050] The fourth step is to select the rigid upper roller with a pressing force of 10mm and a roller speed of 2000r / min, and perform roll bending on the material. Through the combined effect of the compressive stress of the rigid upper roll and the friction between the flexible medium lower roll and the plate, the curvature member of the glass fiber-aluminum alloy hyperhybrid composite is finally obtained.

[0051] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com