Method for forming 30 degree double-R tube of gasification furnace internal component

A gasifier and pipe technology, which is applied in the direction of pipes, pipes/pipe joints/pipes, rigid pipes, etc., can solve the problems of difficult manufacturing, difficulty in product forming, and difficult to control the bending size, shape and rebound rate of pipes, etc. To achieve the effect of simplifying production and processing, controlling size and springback

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

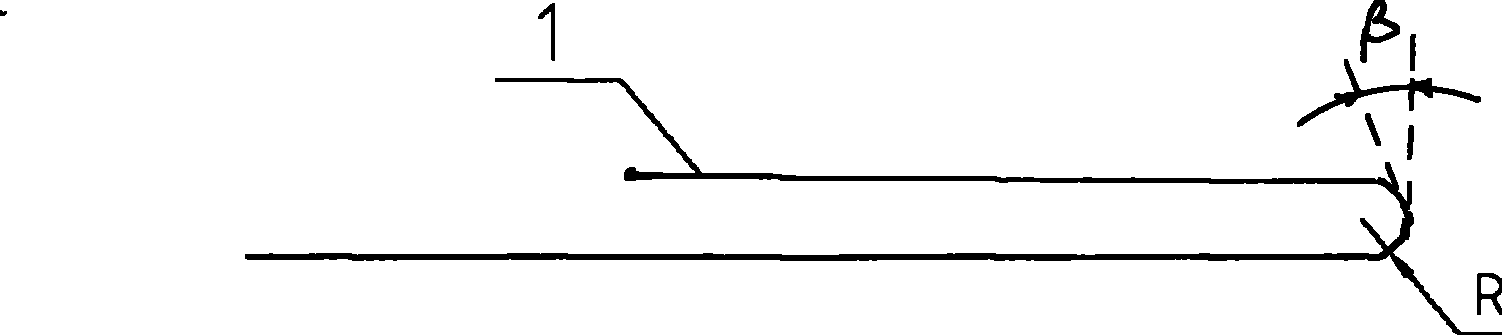

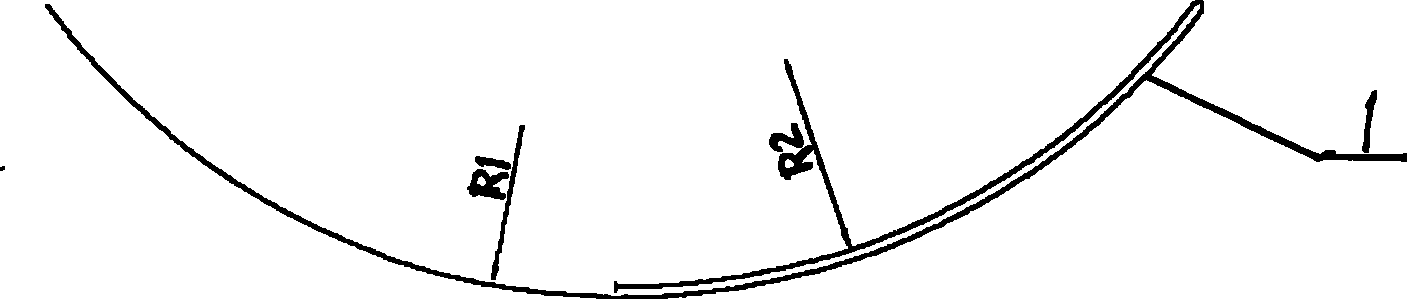

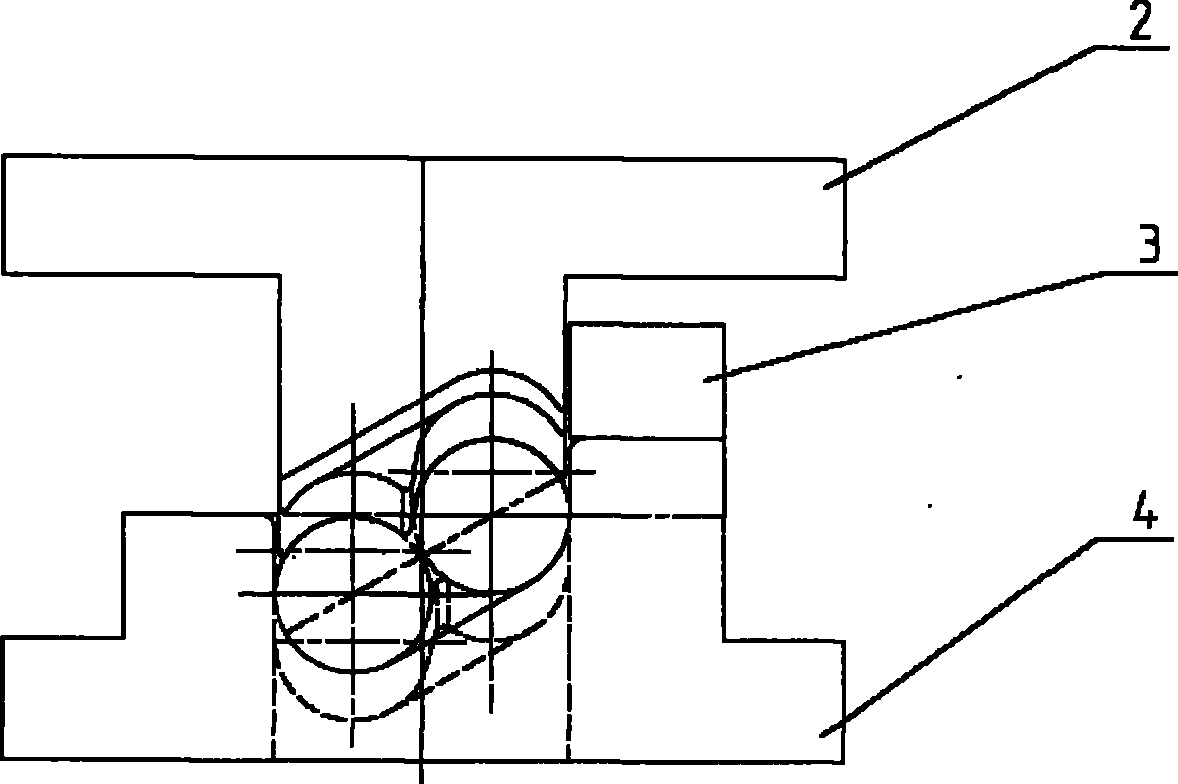

[0026] Such as image 3 As shown, it is a structural schematic diagram of the bending die. The bending die is composed of an upper bending die 2, a limit block 3 and a lower bending die 4. The upper bending die 2 and the lower bending die 4 are combined to limit the The positioning block 3 is arranged on the lower bending die 4 outside the upper bending die 2, and the limiting block 3 limits the vertical movement range of the lower bending die 4, such as Figure 4 , 5 As shown, it is a structural diagram of the upper die of the bending die. The upper die 2 of the bending die is provided with two semicircular holes, and the radius of the hole r1=R1, the radius r2=R2, and the radius of the end of the hole r5=r6=D / 2, the slope of the two holes is 30°, such as Figure 6 , 7 As shown, it is a structure diagram of the lower die of the bending die, the structure of the lower die 4 of the bending die is matched with the upper die 2 of the bending die, and the radius of the semicir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com