Automatic putting device for washing machine and liquid storage and ventilation structures

An automatic feeding and washing machine technology, applied in the field of washing machines, can solve the problems of clogging of washing liquid pipelines, complicated fixing methods of detergent devices, and reduction of user operation steps, etc., and achieve the effect of convenient placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

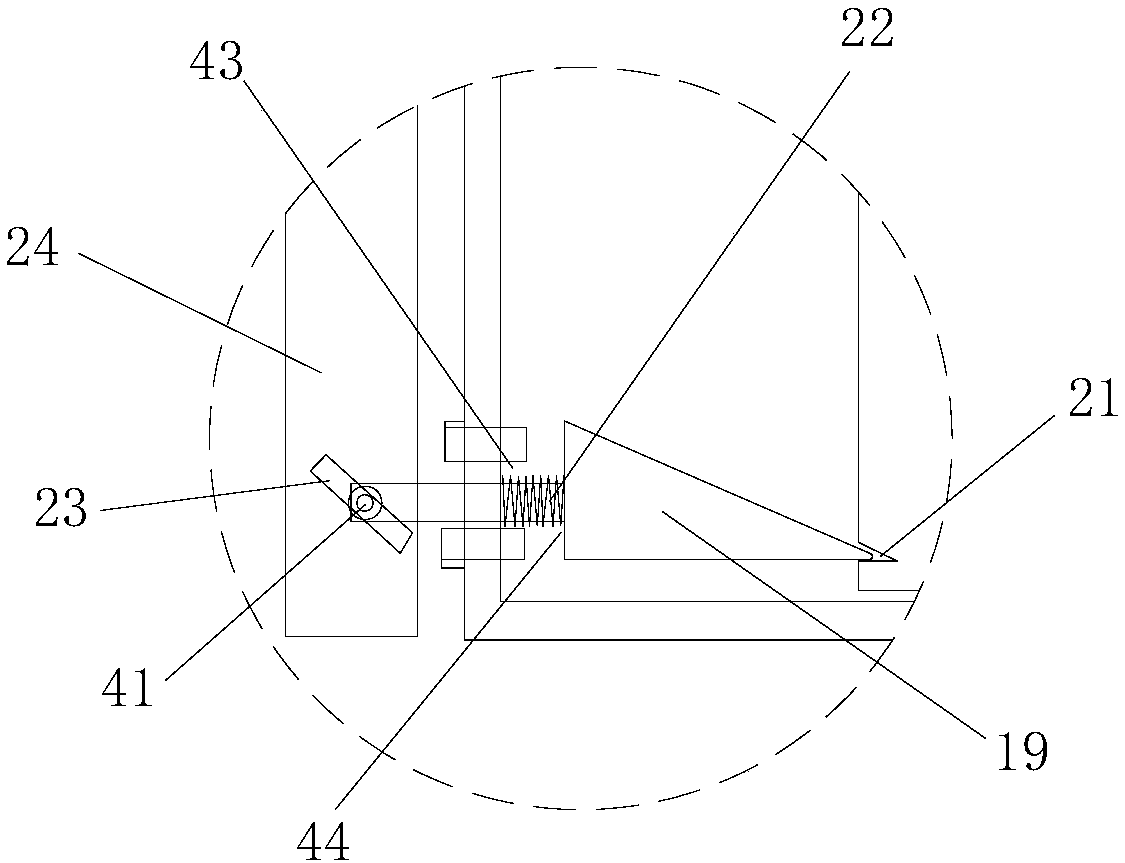

[0058] Such as Figure 5 As shown, a part of the ventilation passage that is formed between the second element 6 and the liquid storage box in this embodiment and communicates with the air vent from the outside is formed by a support protrusion 16, and the support protrusion 16 is located between the second element 6 and the liquid storage box. The boxes are non-sealed and discontinuous with each other, and there is no contact between the supporting second element 6 and the air vent 17, allowing air to pass through.

Embodiment 2

[0060] Such as Figure 5 As shown, the support protrusions 16 arranged at intervals in this embodiment are integrally formed around the air vent 17 of the liquid storage box, the upper part of the support protrusion 16 is in contact with the second element 6, and the support second element 6 is not in contact with the air vent 17 .

Embodiment 3

[0062] The discontinuous support protrusion 16 described in this embodiment is provided on the second element 6 and is located around the connection position between the second element 6 and the valve body 14. The lower part of the support protrusion 16 is in contact with the air vent 17 to support the second element. 6 is not in contact with the air vent 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com