Flexible capacitive-type pressure sensor and preparation method therefor

A technology of pressure sensor and flexible capacitor, which is applied in the field of microelectronics, can solve the problems of small pressure measurement range and poor linear characteristics, and achieve the effect of improving dielectric gauge factor, improving sensitivity, improving dynamic range and linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

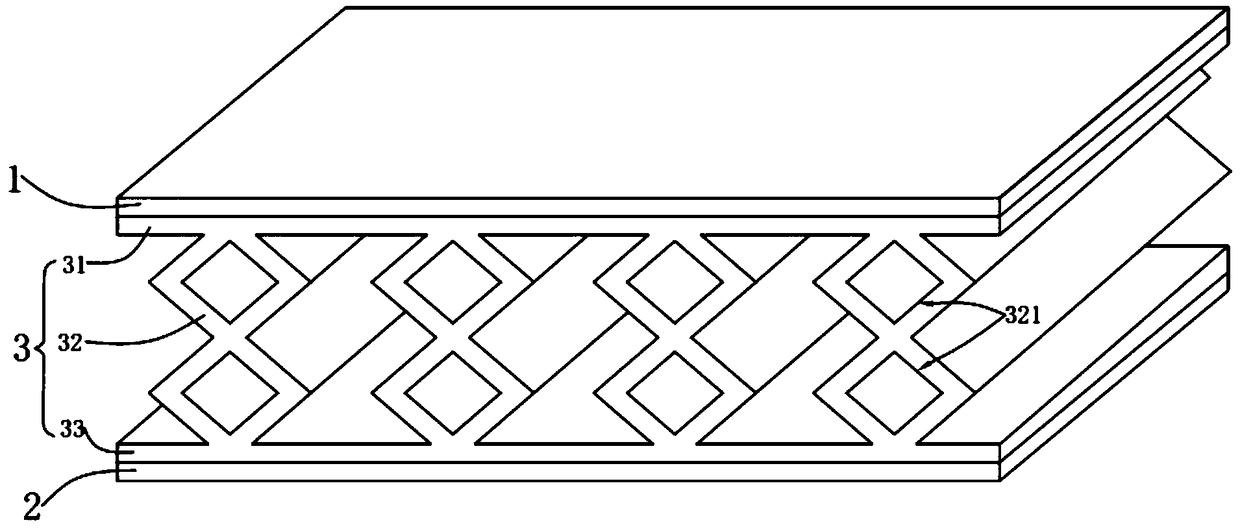

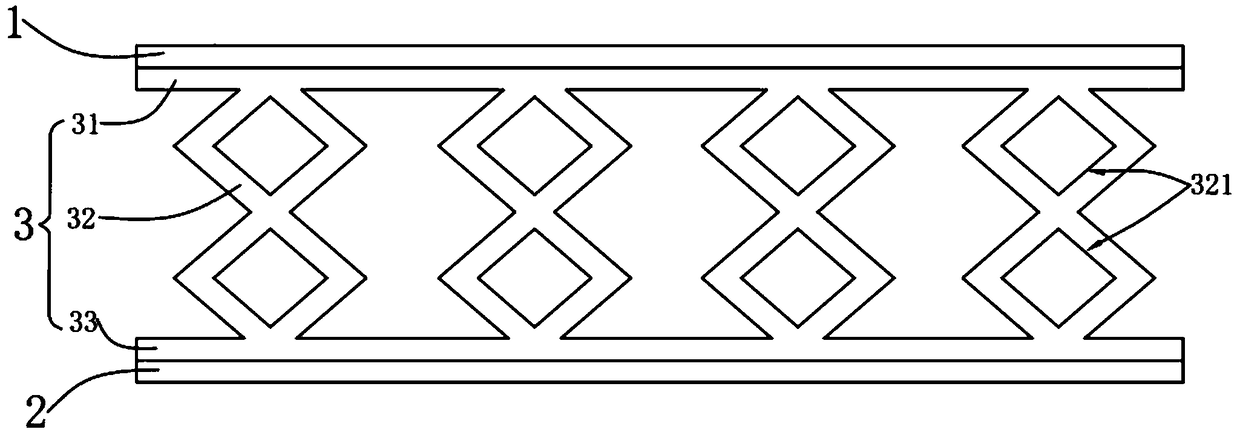

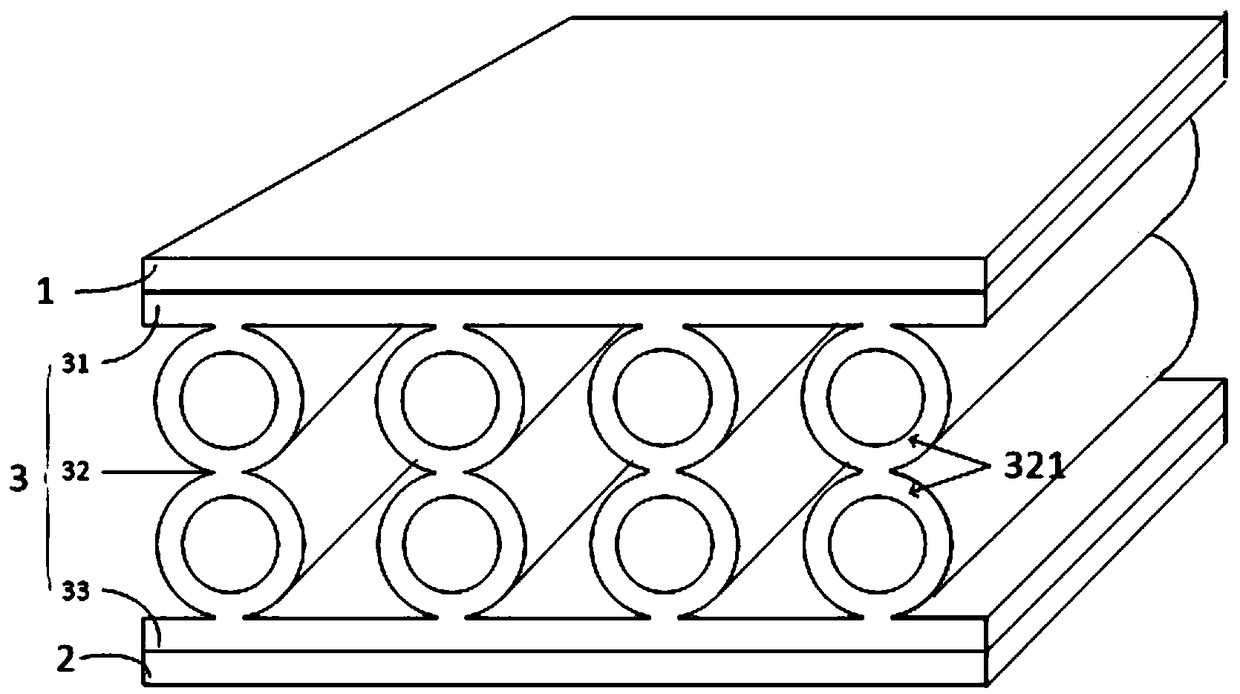

[0032] refer to figure 1 , the present invention provides a flexible capacitive pressure sensor, the flexible capacitive pressure sensor includes an upper electrode 1, a lower electrode 2 and a composite dielectric layer 3 sandwiched between the upper electrode 1 and the lower electrode 2, wherein the upper electrode 1 Both the electrode and the lower electrode 2 are flexible planar plates; the composite dielectric layer 3 has a topological structure.

[0033] Specifically, such as figure 2 As shown, the composite dielectric layer 3 includes a first structural layer 31 connected to the upper electrode 1 , a second structural layer 33 connected to the lower electrode 2 , a deformable layer disposed between the first structural layer 31 and the second structural layer 33 Layer 32, the first structural layer 31 is a flexible planar plate corresponding to the upper electrode 31, and the second structural layer 33 is a flexible planar plate corresponding to the lower electrode 2;...

Embodiment 2

[0037] refer to Figure 5 and Image 6 , the present invention also provides a preparation method for the flexible capacitive pressure sensor of embodiment 1, specifically comprising:

[0038] Prepare to form the upper mold 4 of composite dielectric layer and the lower mold 5 ( Figure 5 with Image 6 , the shaded part indicated by the slash is the upper mold, and the shaded part indicated by the grid is the lower mold), specifically, the upper mold 4 and the lower mold 5 can be prepared by 3D printing technology, combined by snap-fitting, along the bayonet Assembling the upper mold 4 and the lower mold 5 into a complete composite dielectric layer mold with a topological structure, wherein the upper mold 4 includes a plurality of first columns arranged at intervals and a first cavity surrounding the first columns; The lower mold 5 includes a plurality of second cylinders arranged at intervals and a second cavity around the second cylinders. The cross-sections of the first cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com