Food processor

A technology for food processing machines and heating cups, which is applied to heating devices, utensils with integral electric heating devices, cooking utensils, etc., can solve problems such as food processing machines not working properly, and avoid dry burning and impact damage. , the effect of reducing the probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

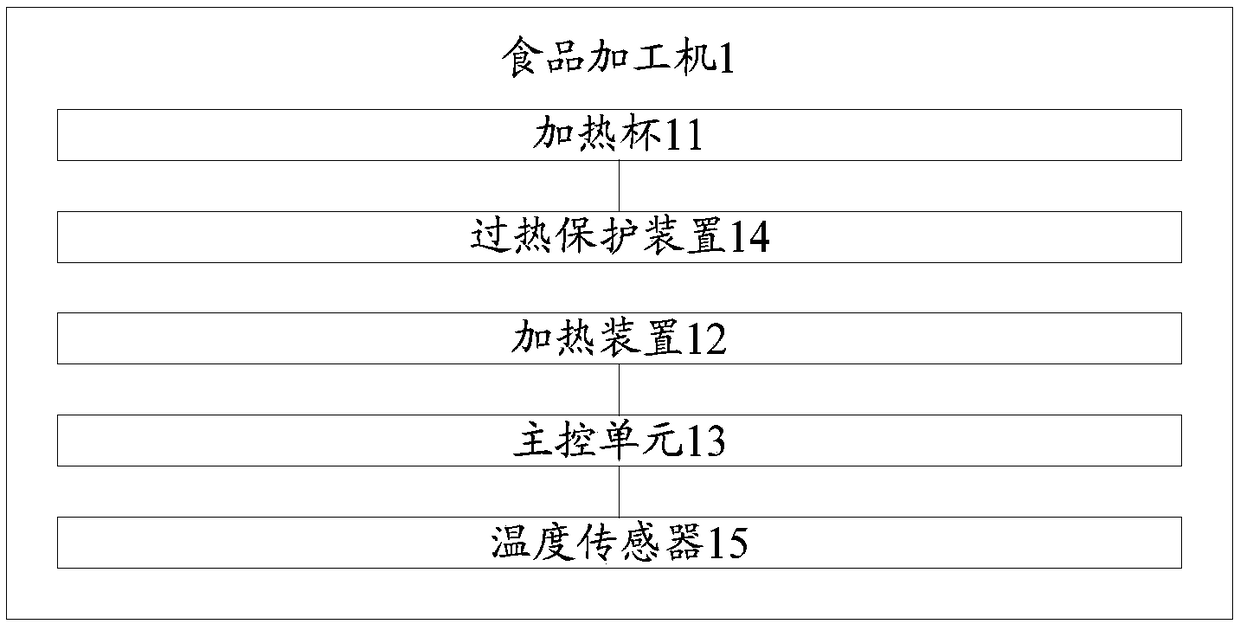

[0039] A food processor such as figure 1 As shown, the food processor 1 may include a heating cup 11, a heating device 12 and a main control unit 13. The heating device 12 is used to heat the heating cup 11; A temperature sensor 15 is provided; the temperature sensor 15 is connected to the main control unit 13;

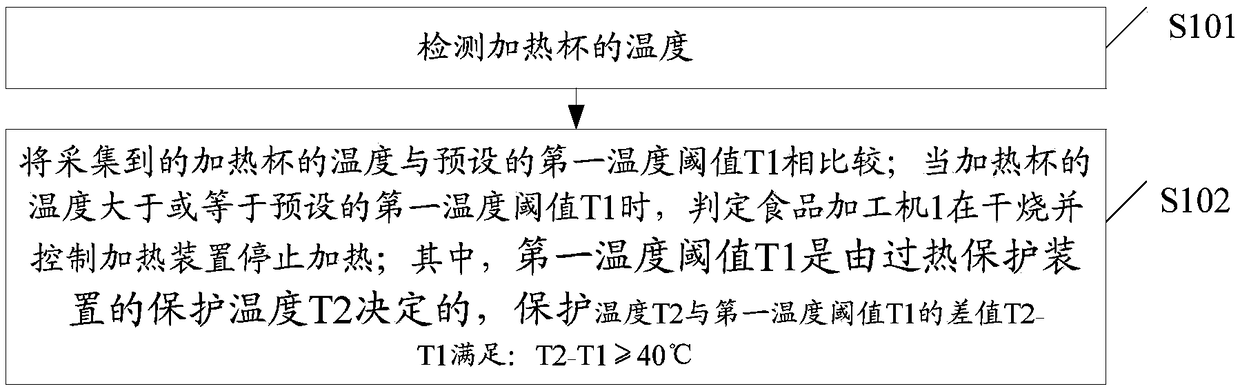

[0040] A temperature sensor 15 is used to detect the temperature of the heating cup 11;

[0041] The main control unit 13 is used to compare the collected temperature of the heating cup 11 with the preset first temperature threshold T1; when the temperature of the heating cup 11 is greater than or equal to the preset first temperature threshold T1, it is determined that the food processing The machine 1 is dry burning and controls the heating device 12 to stop heating;

[0042] Wherein, the first temperature threshold T1 is determined by the protection temperature T2 of the overheat protection device, and the difference T2-T1 between the protection temperature T2 an...

Embodiment 2

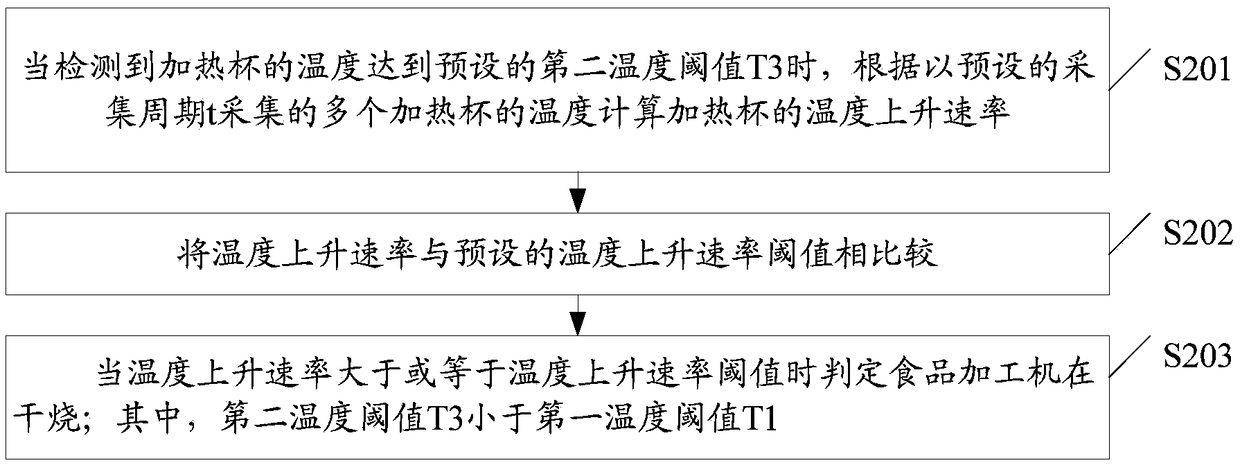

[0050] In this embodiment, on the basis of the first embodiment, a dry burning judgment scheme is added.

[0051] Optionally, the main control unit 13 is further configured to: before judging whether the food processor is dry-boiling according to the first temperature threshold, judge whether the food processor 1 is dry-boiling according to the temperature rise rate of the heating cup 11 .

[0052] In the embodiment of the present invention, since the heating device 12 (such as a heating tube) will have a certain thermal inertia when heating, and there is a certain hysteresis in the detection of the temperature sensor 15, when the current temperature T is detected by the temperature sensor 15, the heating The actual temperature of the cup 11 is generally greater than T, and when the power of the heating device 12 is larger, the rate of temperature rise is faster, and the hysteresis of the temperature detected by the temperature sensor 15 is more obvious, and the thermal inertia...

Embodiment 3

[0065] The solution of this embodiment further limits the value ranges of the second temperature threshold T3 and the collection period t on the basis of the second embodiment.

[0066] Optionally, the second temperature threshold T3 satisfies: T3≥100°C.

[0067] In the embodiment of the present invention, when the temperature of the heating device 12 is lower than 100°C, the conduction effect of water is limited, and the temperature rise rate of the heating device 12 is relatively close. Misjudgment is caused. When the temperature of the heating device 12 exceeds 100°C, the water conduction effect is more obvious. When there is water, the temperature rise rate of the heating device 12 is relatively slow and gradually tends to be stable. When dry burning, the temperature rise rate of the heating device 12 It is faster and the rising speed remains basically the same, so the dry burning situation can be judged quickly and accurately according to this difference.

[0068] In the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com