Rotor piece manufacturing method and mold

A manufacturing method and rotor sheet technology, which are applied in the directions of manufacturing tools, centering/balancing rotors, manufacturing stator/rotor bodies, etc., can solve problems such as low work efficiency, unstable rotor core, and unavoidable concentricity errors, etc. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

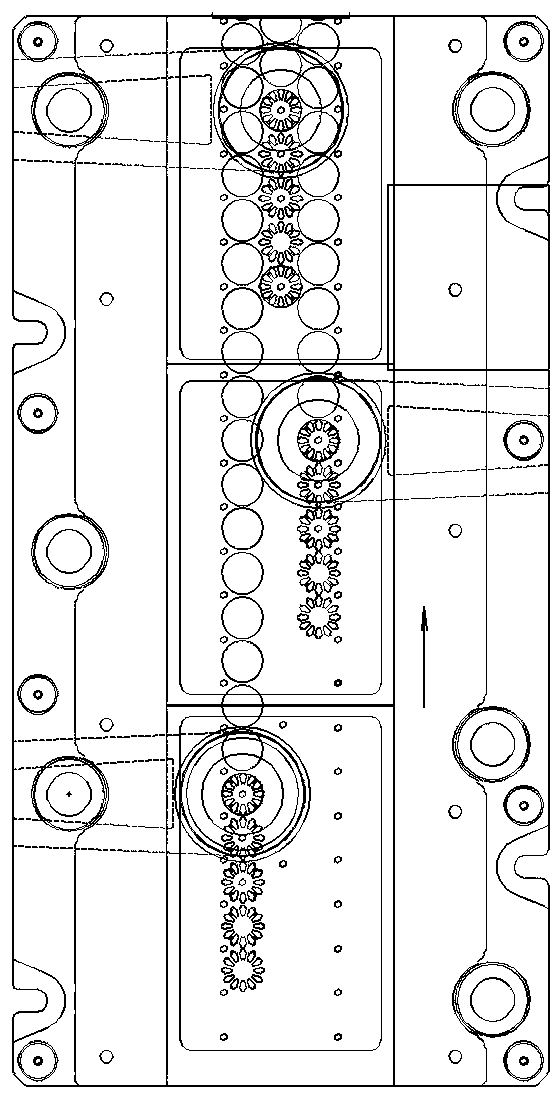

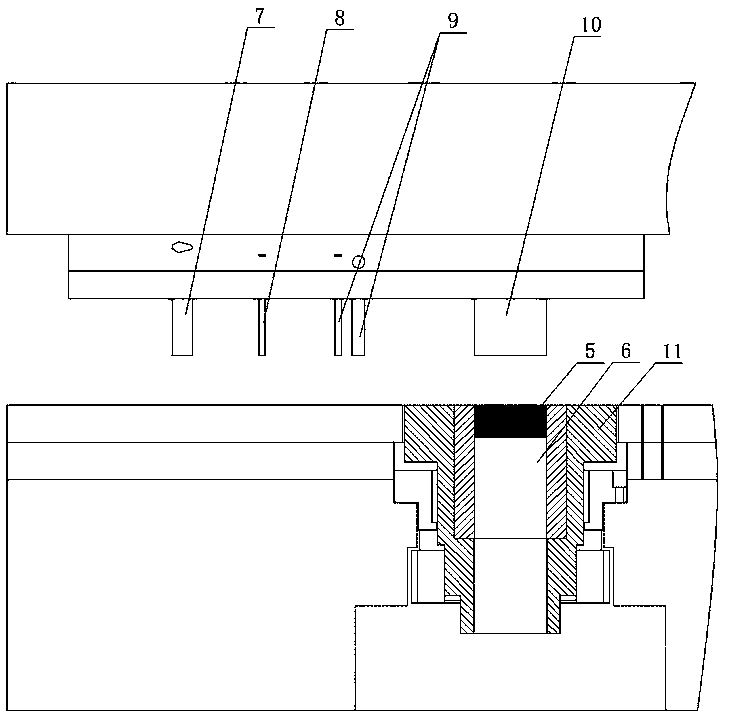

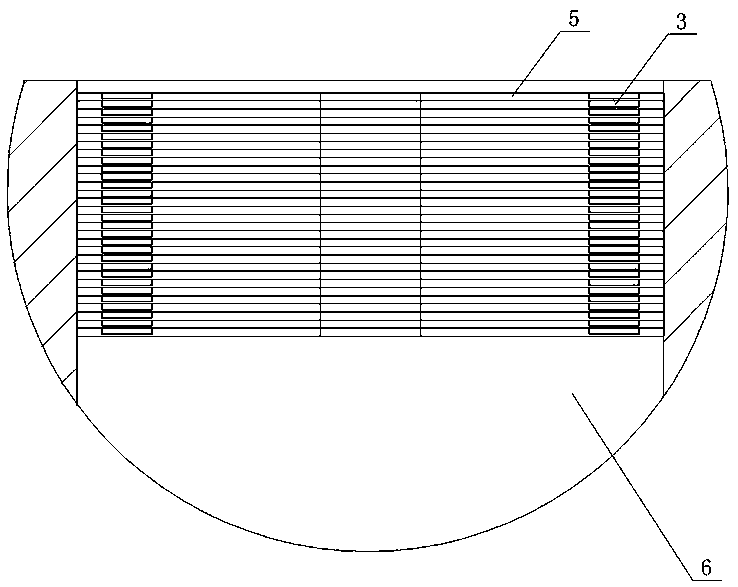

[0016] As shown in the figure, the method for manufacturing the rotor sheet of the present invention includes the following steps: the iron plate for making the rotor sheet is conveyed step by step, and the first, second, third and fourth processes are arranged in sequence on the step-by-step conveying path. The first station is equipped with a first punching head 7 to punch out the blade slot 1 on the iron plate, the second station is equipped with a second punching head 8 to punch out the metering hole 2 on the iron plate, and the third station is set A third stamping head 9 punches out the stacking riveting point 3 and the central axis hole 4 on the iron plate, the stamping position of the stacking riveting point 3 is the same as that of the metering hole 2, and the fourth station is provided with a fourth stamping head 10 to make The rotor sheet 5 is blanked into the blanking cavity 6 and riveted with the previous rotor sheet in the blanking cavity 6 , and the blanking cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com