Roll-over stand for maintenance of vehicle engine

A technology of automobile engine and turning frame, which is applied in the direction of workbench and manufacturing tools, etc. It can solve the problems of automobile engine handling, positioning and installation, inconvenient placement and use of maintenance tools, and troublesome cleaning of oil waste, etc., and achieves simple structure and safety Performance-enhancing, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific examples. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

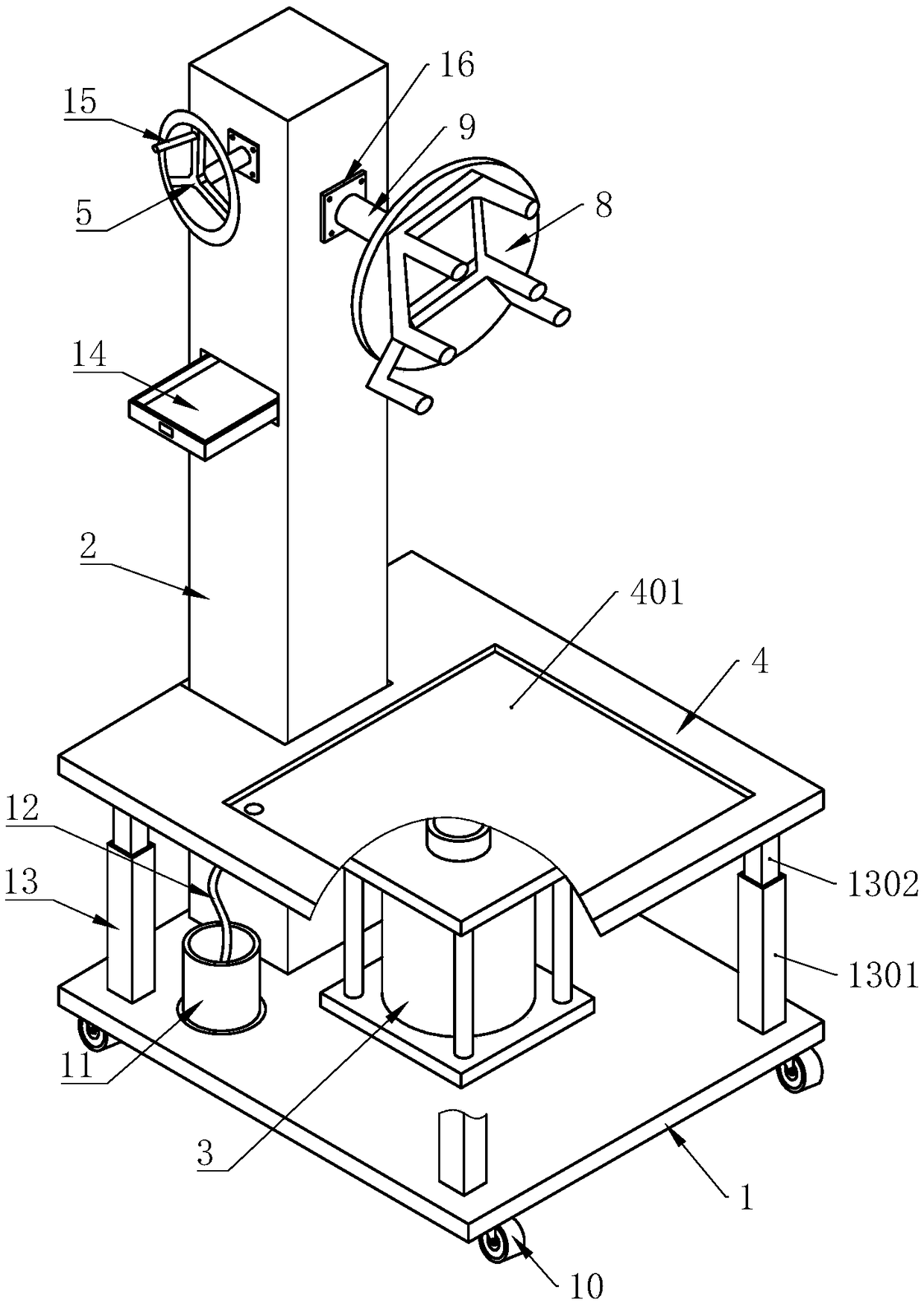

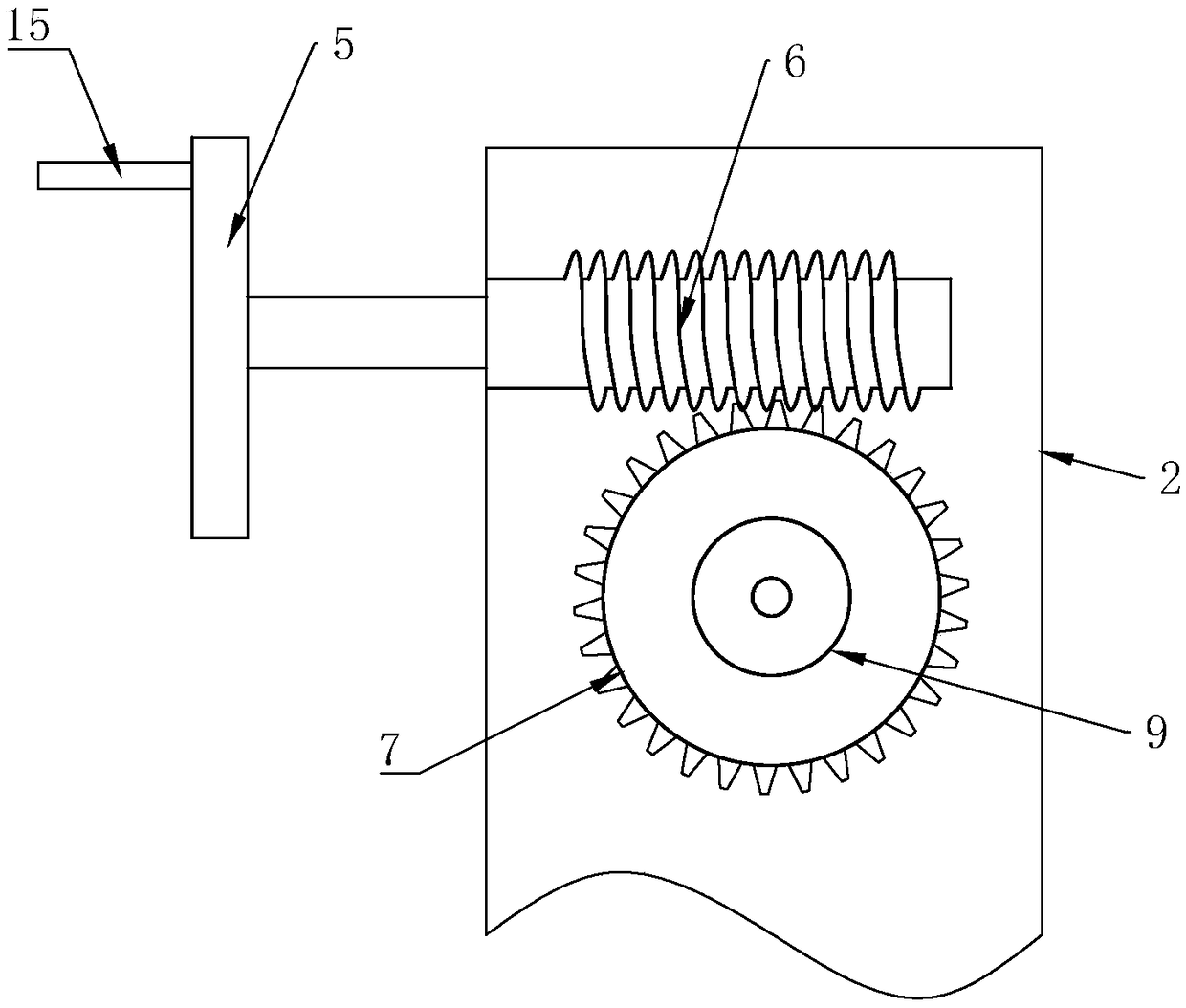

[0029] Such as figure 1 and figure 2 Shown, a kind of reversing stand for automobile engine maintenance, comprises mounting frame, elevating mechanism and indexing mechanism; Mounting frame comprises base plate 1 and the column 2 that is arranged on the base plate 1, and column 2 is the shell structure of internal hollow, and column 2 The side close to the bottom plate 1 is fixedly installed; the lifting mechanism includes a hydraulic cylinder 3 and a lifting plate 4, the hydraulic cylinder 3 is fixedly installed on the bottom plate 1, and is installed in the middle of the bottom plate 1, and the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com