Automobile spare tire storage mechanism

A technology for spare tires and automobiles, which is applied to the arrangement of spare tires, vehicle components, transportation and packaging, etc. It can solve the problems of inconvenient disassembly and installation, personnel injuries, etc., and achieve the effect of avoiding easy injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

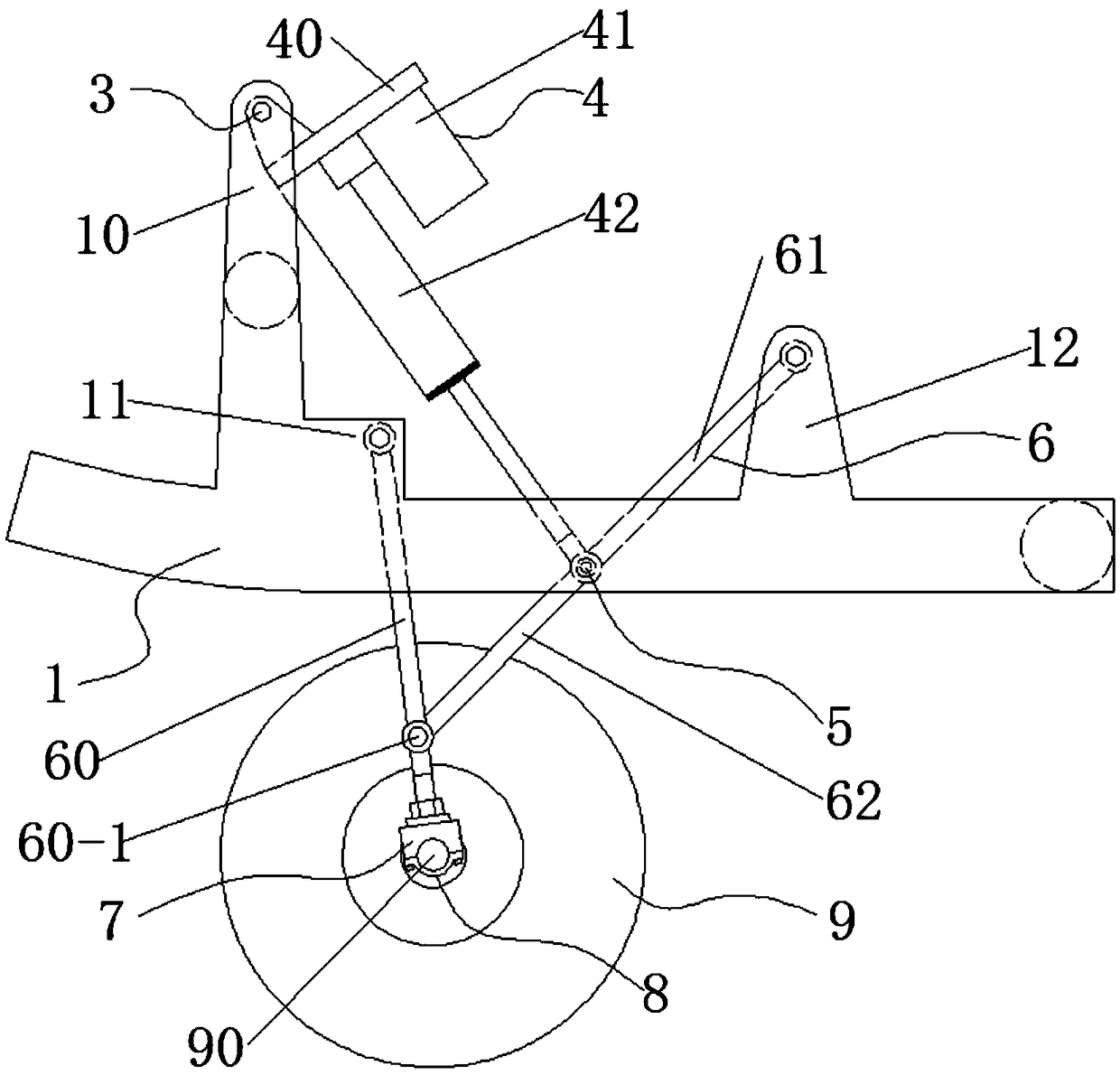

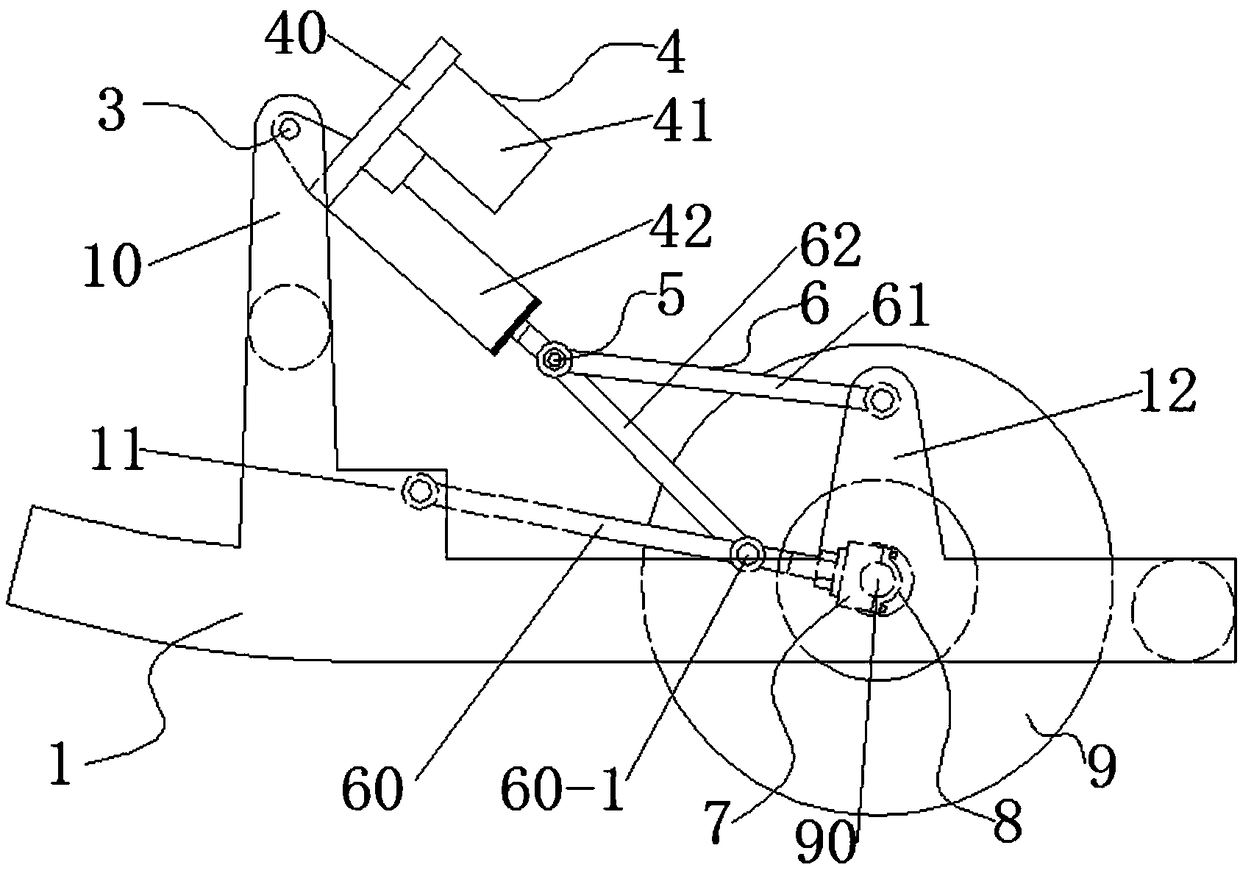

[0023] In this car spare tire storage mechanism, when the car spare tire needs to be folded and stored, the wheel hub 9 is rolled between the two side frame plates 1, and then the hub shaft 90 is placed in the middle of the half shaft seat 7, and then the half shaft cover 8 Tighten the bolts on the half shaft seat 7 to lock the hub shaft 90 firmly, then start the miniature electric push rod 4, the push rod motor 41 drives the electric push rod 42 to shrink, and the first connecting rod 61 and the second connecting rod 62 start from the collinear The state is that the hinge point at the end of the electric push rod 42 is the apex and is folded into an acute angle. During this process, the connecting rod one 61 rotates clockwise around the third hinge part 12. During the folding process of the connecting rod two 62, the connecting rod two 62 By being hinged with the hinge hole 60-1, the support rod 60 is pulled to rotate counterclockwise around the second hinge part 11, and then ...

Embodiment 2

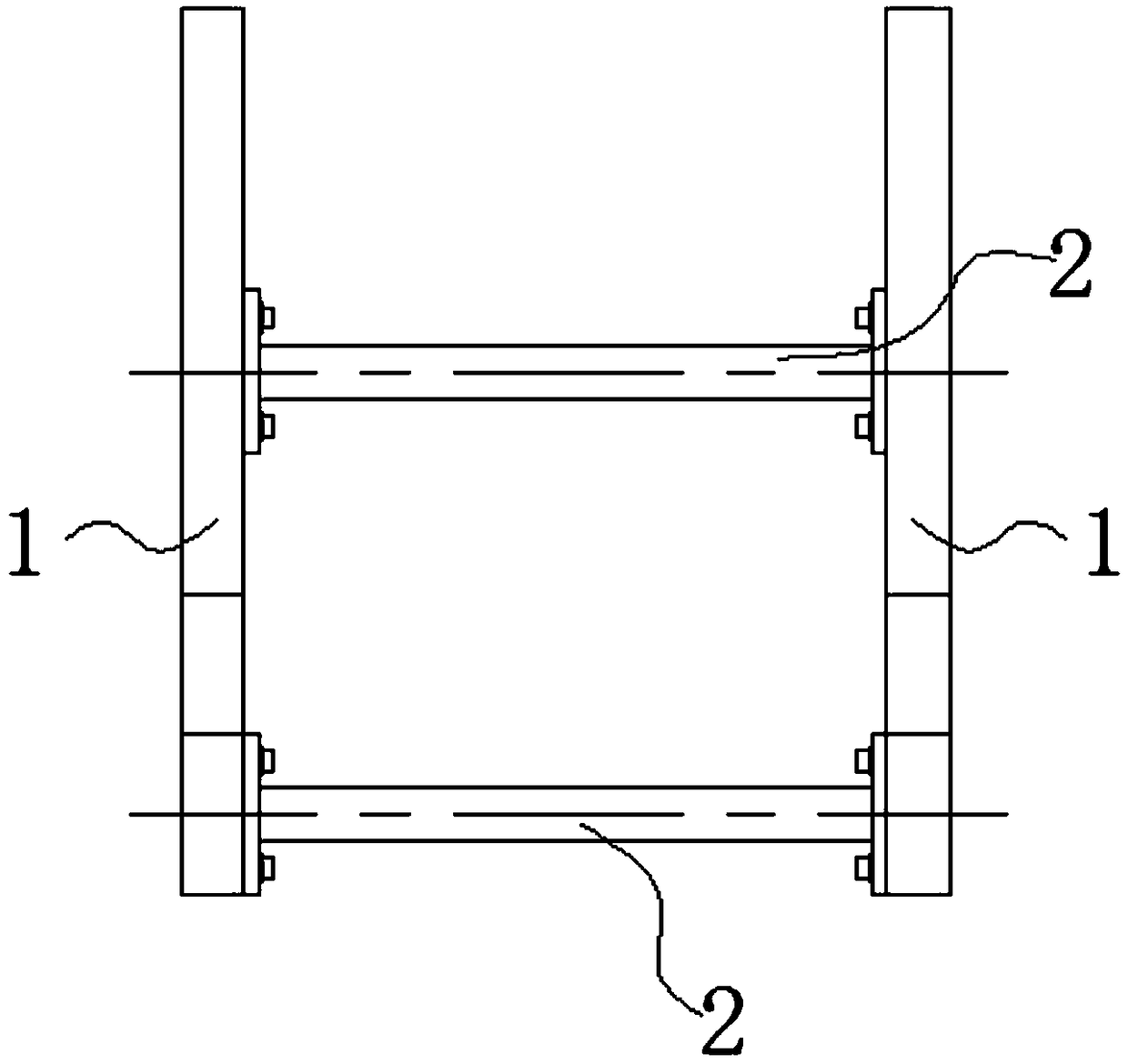

[0026] The connecting rod group 6 is provided with two groups, and they are respectively located inside the side frame plate 1, which ensures the stability of the folding storage and automatic unfolding action; It is circular, which facilitates the installation and locking of the half shaft seat 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com