Interlaced Laying System and Application Method of Honeycomb Porous Structure Cotton

A porous structure, staggered technology, used in textiles, papermaking, non-woven fabrics, etc., can solve the problems of inability to form staggered multi-layer textiles, single laying direction, etc., and achieve the effect of rich laying directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

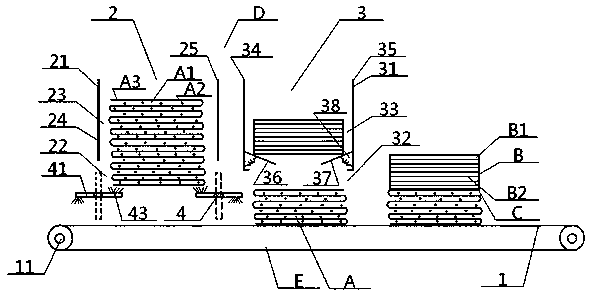

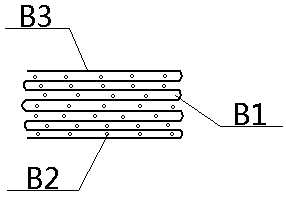

[0052] see Figure 1 to Figure 6 , a kind of staggered laying system of honeycomb porous structure cotton, comprising a laying unit D and a transmission unit E, the transmission unit E includes a conveyor belt 1 and a driving roller 11, the two ends of the conveyor belt 1 are respectively connected to the outer circumference of the driving roller 11 Connected, a laying unit D is arranged directly above the middle of the conveyor belt 1; the laying unit D includes a left and right laying device 2 and a front and rear laying device 3 arranged side by side along the conveyor belt 1, and the left and right laying device 2 includes The left and right guides 21 and the left and right cotton outlets 22 arranged directly below, the front and rear laying device 3 includes the front and rear guides 31 and the front and rear cotton outlets 32 arranged directly below, the left and right guides 21, front and rear guides 31 are all hollow structures. The left and right inner cavities 23 pro...

Embodiment 2

[0055] Basic content is the same as embodiment 1, the difference is:

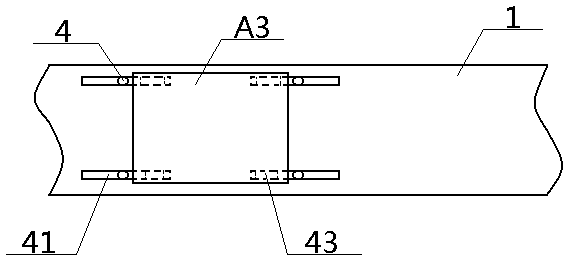

[0056] The left and right cotton output areas 22 are provided with four weight-limiting cotton output structures 4 with the same structure. A single weight-limiting cotton output structure 4 includes horizontal weight-limiting tubes 41 and vertical rotating tubes 42, both of which are hollow structures. The horizontal weight-limiting tubes The top of one end of 41 is provided with positive air outlet 43, and the bottom of the other end of horizontal weight-limiting tube 41 is provided with anti-air outlet 44, and the middle position of horizontal weight-limiting tube 41 is vertically connected with the inner end of vertical rotation tube 42, and vertical rotation The outer end of pipe 42 is connected with rotating bearing 45, and the inner cavity of horizontal weight-limiting pipe 41, positive air outlet 43, reverse air outlet 44, and vertical rotating pipe 42 are all connected to each other; four weight-lim...

Embodiment 3

[0059] Basic content is the same as embodiment 1, the difference is:

[0060] The left and right sides of described front and rear inner cavity 33 are respectively provided with mutually parallel front and rear left cavity plate 34, front and rear right cavity plate 35, and the inner surfaces of front and back left cavity plate 34, front and rear right cavity plate 35 are respectively connected with the left limit weight springboard. 36. The inner ends of the right weight-limiting springboard 37 are fixedly connected, and the outer ends of the left weight-limiting springboard 36 and the right weight-limiting springboard 37 extend downward in the direction of the central axis of the front and rear inner cavity 33. The outer ends of the heavy rebounding plate 36 and the right limiting weight rebounding plate 37 are lower than the corresponding inner ends respectively, the distance between the outer end of the left limiting heavy rebounding plate 36 and the outer end of the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com