A kind of manufacturing process of honeycomb porous structure cotton

A technology of porous structure and manufacturing process, which is applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of single laying direction, inability to form interlaced multi-layer textile bodies, single internal structure, etc., and achieve strong adjustability, Ease of operation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

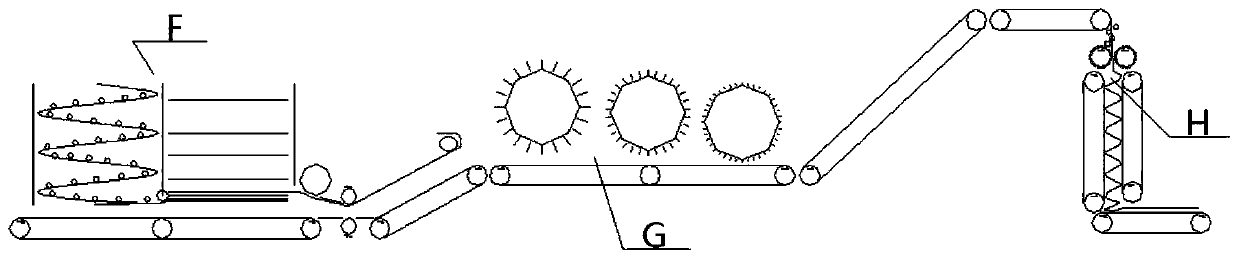

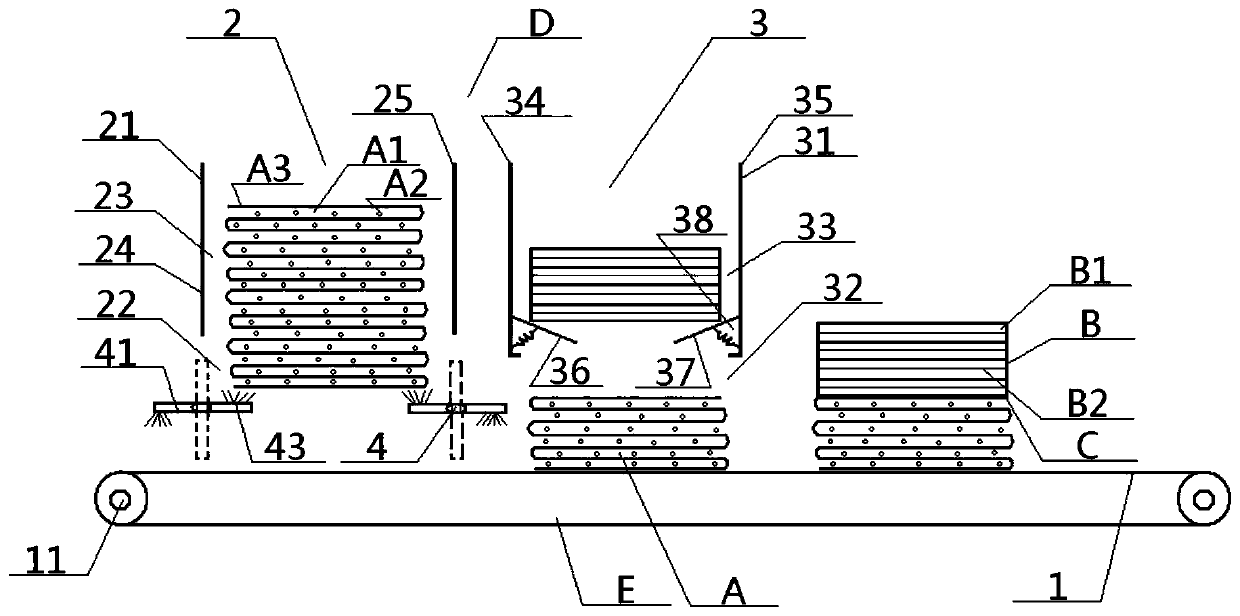

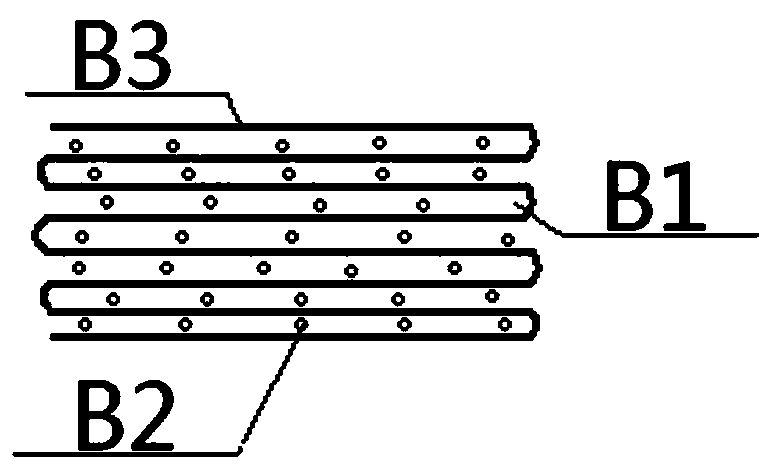

[0066] see Figure 1 to Figure 20 , a manufacturing process of honeycomb porous structure cotton, comprising a laying stage operation process, a carding stage operation process and a web laying stage operation process carried out in sequence, and the laying stage operation process refers to that the laying part lays up the fiber web operation, the carding stage operation process refers to that the carding part combs the product of the laying stage operation process, and the said web laying stage operation process refers to that the web laying part performs reciprocating web laying on the product of the carding stage operation process, and laying The outlet of the laying part communicates with the feed port of the laying part through the carding part; the laying part is a staggered laying system F, including a laying unit D and a transmission unit E, and the transmission unit E includes a conveyor belt 1 With the driving roller 11, the two ends of the conveyor belt 1 are respec...

Embodiment 2

[0069] Basic content is the same as embodiment 1, the difference is:

[0070] The ends of the No. 1 roller body G51, the No. 2 roller body G61, and the No. 3 roller body G71 are all provided with a rotating drive shaft G10. Ends carry out transmission cooperation, and the central part of the rotating drive shaft G10 is connected with the output end of the hoisting motor G14 through the hoisting rope G13.

Embodiment 3

[0072] Basic content is the same as embodiment 1, the difference is:

[0073] The No. 1 needle G52, the No. 2 needle G62, and the No. 3 needle G72 have the same structure, and they all include a needle bar G8 and a needle head G9. The inner end of the needle bar G8 is connected to the No. 1 roller body G51, the No. The side circumference of the third roller body G71 is connected, the outer end of the needle bar G8 is connected with the inner end of the needle head G9, the outer end of the needle head G9 extends outward, the outer end of the needle head G9 is narrower than its inner end, and the outer end of the needle head G9 The side wall is an inner concave arc surface G91; two sides of the needle bar G8 are respectively provided with a sliding groove G81, and the inside of the sliding groove G81 is provided with a hollow slider G82 for sliding cooperation with it, and the inside of the hollow slider G82 A movable ball G83 is provided, and the hollow slider G82 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com