A preparation system for honeycomb porous structure cotton

A porous structure and preparation system technology, applied in the field of textile machinery, can solve the problems of single laying direction, single internal structure, and inability to form interlaced multi-layer textile bodies, and achieve strong adjustability, easy operation, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

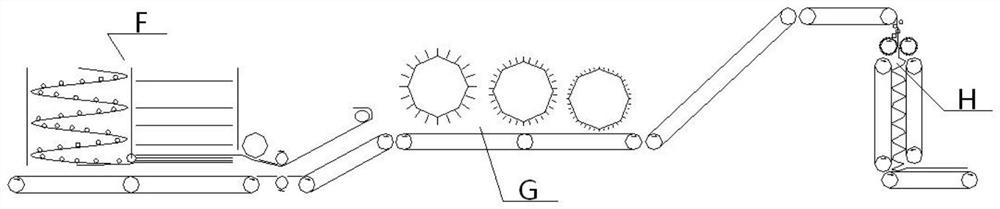

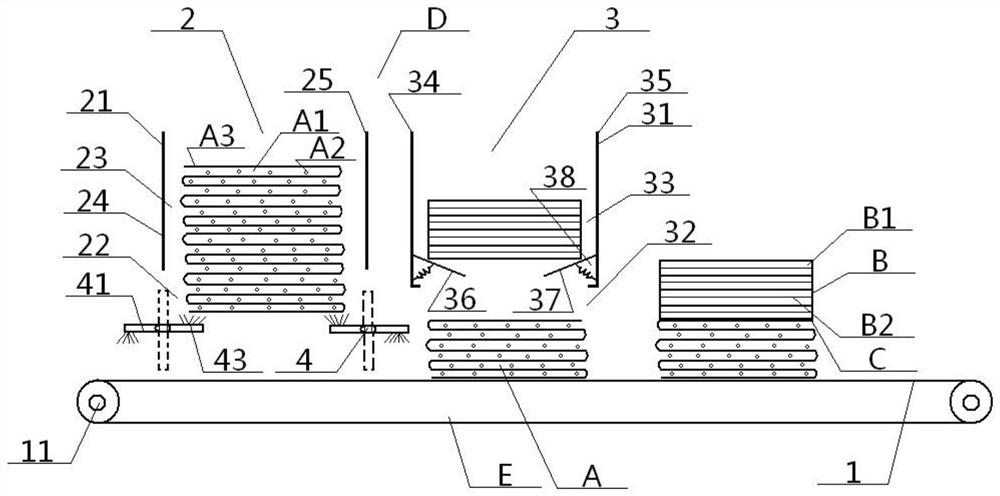

[0049] see Figure 1 to Figure 20 , a preparation system for honeycomb porous structure cotton, comprising a laying part, a carding part and a web laying part, the discharge port of the laying part communicates with the feed port of the web laying part through the carding part;

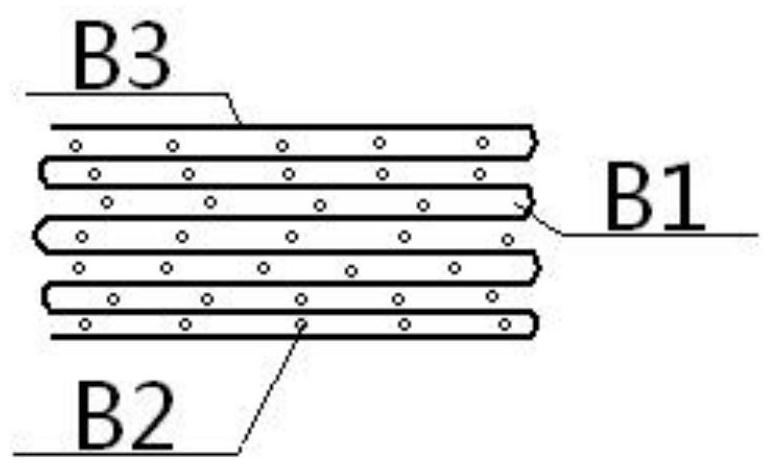

[0050] The laying part is a staggered laying system F, which includes a laying unit D and a transmission unit E. The transmission unit E includes a conveyor belt 1 and a driving roller 11. Both ends of the conveyor belt 1 are in contact with the outer sides of the driving roller 11. Connected, a laying unit D is arranged directly above the middle of the conveyor belt 1; the laying unit D includes a left and right laying device 2 and a front and rear laying device 3 arranged side by side along the conveyor belt 1, and the left and right laying devices 2 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com