Ballastless track slab connecting piece and ballastless track

A ballastless track and connecting piece technology, applied in the direction of track, road, ballast layer, etc., can solve the problems of damaged fixed connection, reduced fixing effect of connecting piece, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

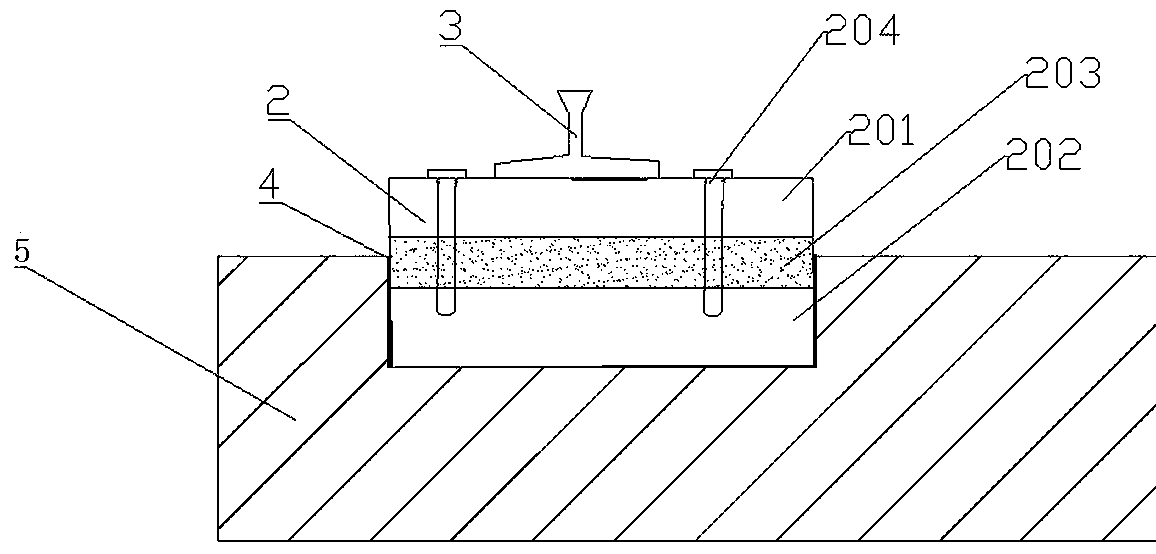

[0030] Such as Image 6 It is a schematic diagram of the structure of a ballastless track of the present invention. Image 6 It includes a track plate 5, a support block 2, a mortar layer 6 and a base body 7, wherein the support block 2 is fixed on the track plate 5, the support block 2 supports a steel rail 3, and a mortar layer 6 and a base body are respectively provided under the track plate 5 7. There is also a waterproof layer, etc. (shown in the picture).

[0031] Figure 1-2 It is a schematic diagram of the connection between the support block 2 and the track plate 5 in a specific embodiment, figure 2 Yes figure 1 As shown in the figure, the support block 2 is located on the track plate 5, and the steel rail 3 is fixed on the support block 2. Wherein, the track slab 5 is in contact with the ground. In a specific embodiment, the ground may be a mortar layer and a base 7. The base 7 is usually a concrete layer. The track slab 5 is provided with a cavity; the support block is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com