Patents

Literature

34results about How to "Increase the length of the runner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

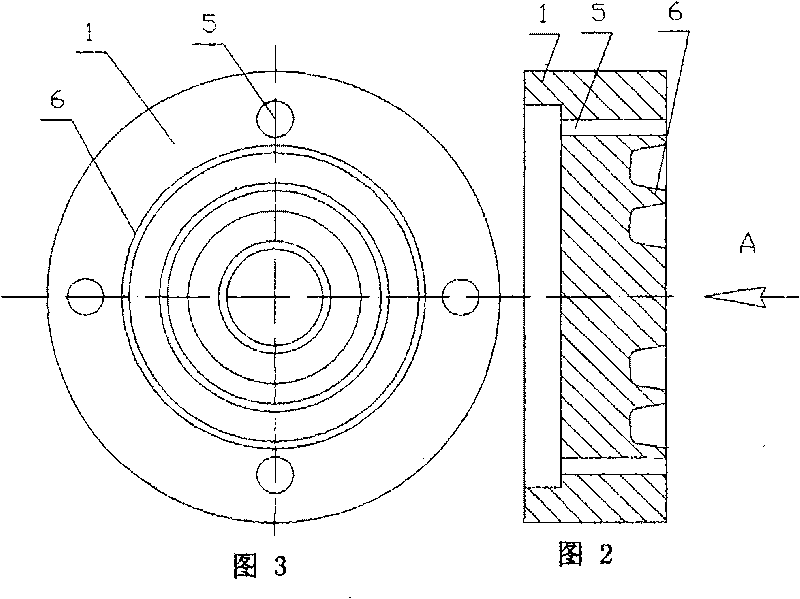

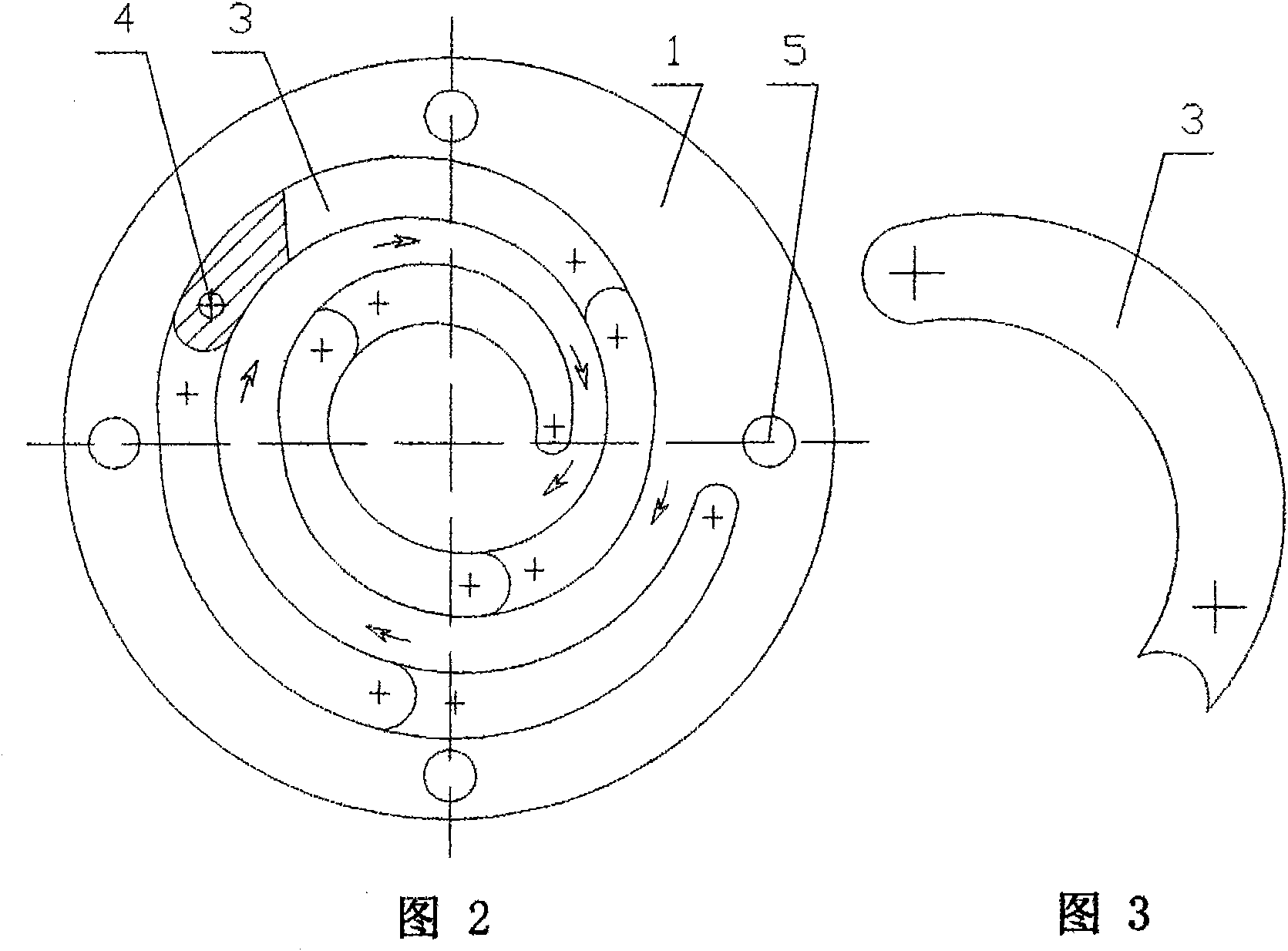

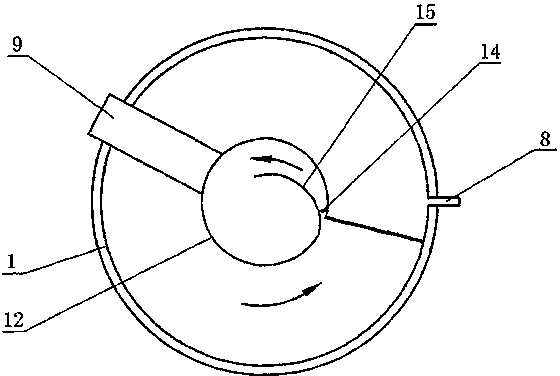

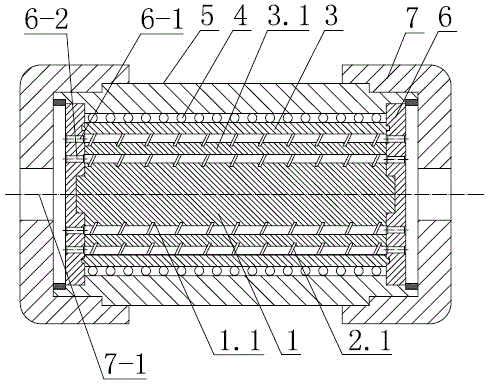

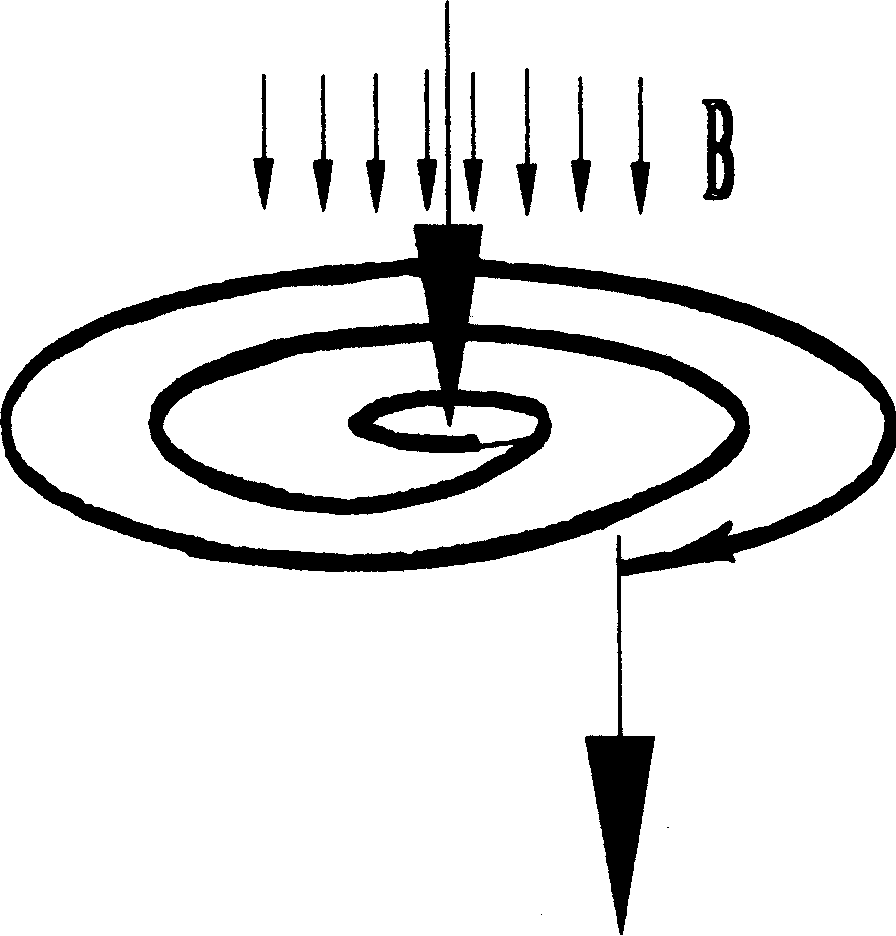

Magnetorheological valve of helical fluid channel

InactiveCN101245799ASimple structureEasy to manufacture and installNon-rotating vibration suppressionFluid dynamicsPath lengthMagnetorheological fluid

The invention provides a magneto-rheological fluid (MRF) valve of a spiral liquid passage, which mainly solves the problem of nonlinear flow of the MRF along the liquid passage in the MRF valve, enlarges the flowing path length of the electro-magneto-rheological fluid, improves the utilization ratio of the line of magnetic force, improves the pressure difference of the controllable fluid of the electro-magneto-rheological fluid under the equivalent current intensity and unchangeable magnetic gap, and achieves the objects of saving energy and reducing the dimension of the MRF valve. The proposal of the MRF valve is that the corresponding end surface of a positioning disc to a magnetic guide disc is provided with a nonlinear liquid passage. The MRF valve has the advantages of simple structure of MRF valve, convenient manufacture and installation, increasing no volumes of the MRF valve, and enlarging the control range of the MRF valve.

Owner:黑龙江科大科技开发有限公司

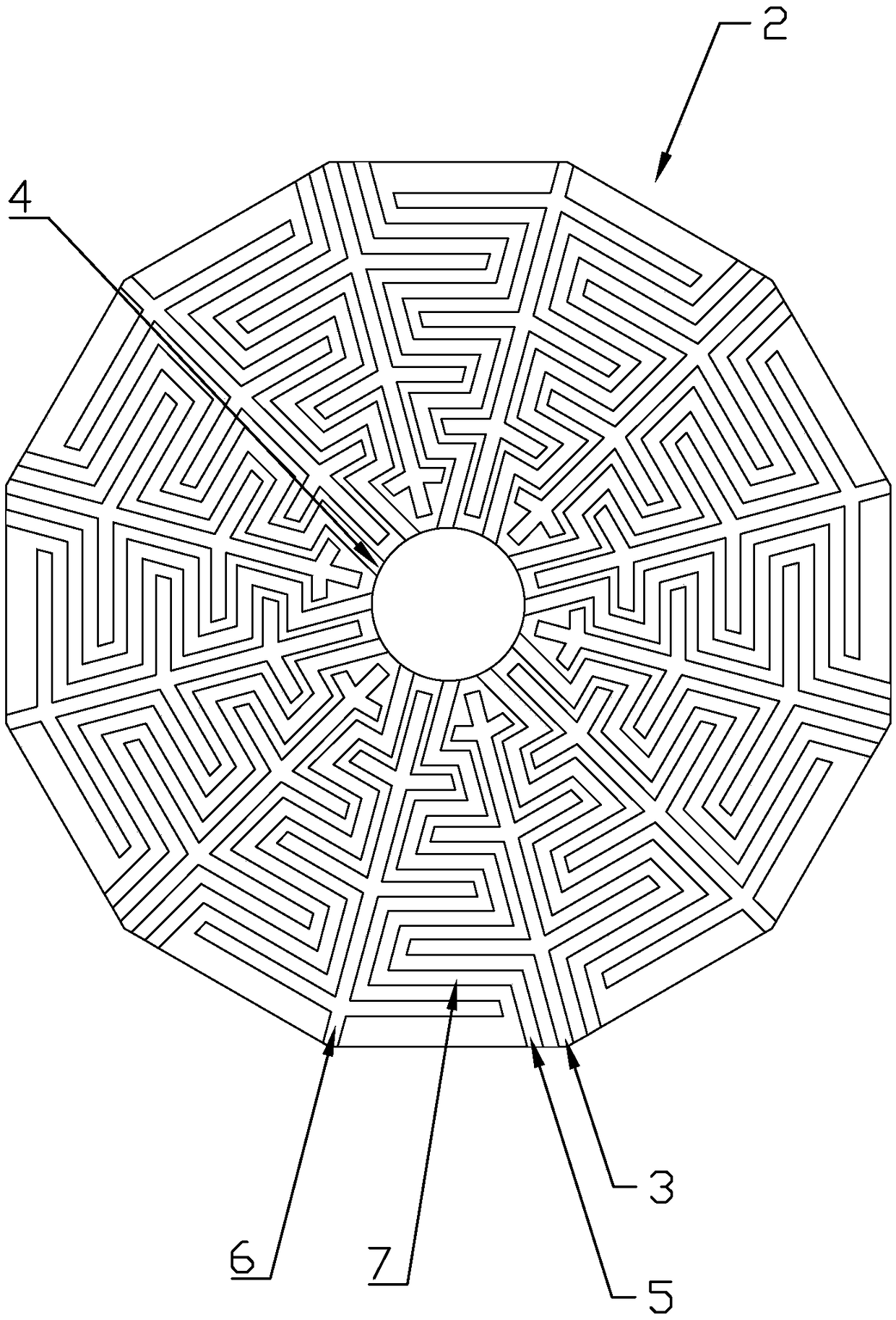

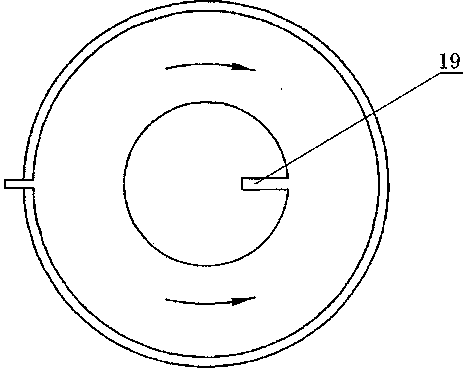

Active-draining fuel battery bipolar plate with veined interdigitated flow field

The invention relates to an active-draining fuel battery bipolar plate with a veined interdigitated flow field. The active-draining fuel battery bipolar plate comprises a bipolar plate body provided with the interdigitated flow field which is circular or equilateral polygonal; with the central point of the flow field as the center of a circle, the interdigitated flow field a local flow field whichis divided into n parts averagely, wherein n is not less than 2; the local flow field comprises a reaction gas inlet, a reaction gas outlet, a veined gas inlet channel, and a serpentine gas outlet and water drain channel, wherein the reaction gas inlet is arranged at the outer end of the veined gas inlet channel, and the reaction gas outlet is arranged at the outer end of the serpentine gas outlet and water drain channel. According to the technical scheme, mass transfer of the whole battery is more uniform; the design of the active-draining channel can promote draining of water in the gas outlet channel, water generated in the reaction can be diffused to the gas outlet channel more easily, and further water retention at the gas inlet is reduced.

Owner:INST OF LASER & OPTOELECTRONICS INTELLIGENT MFG WENZHOU UNIV

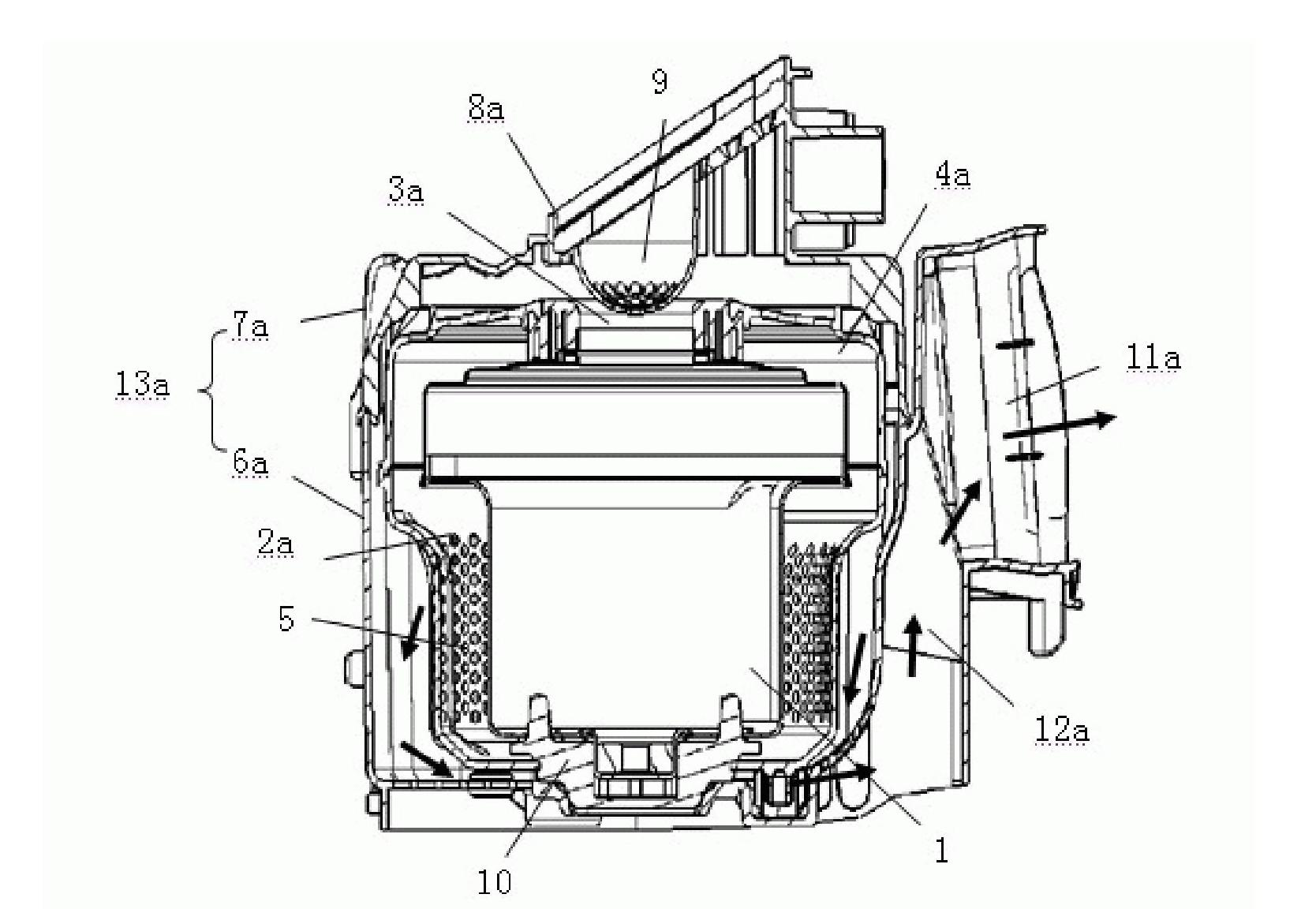

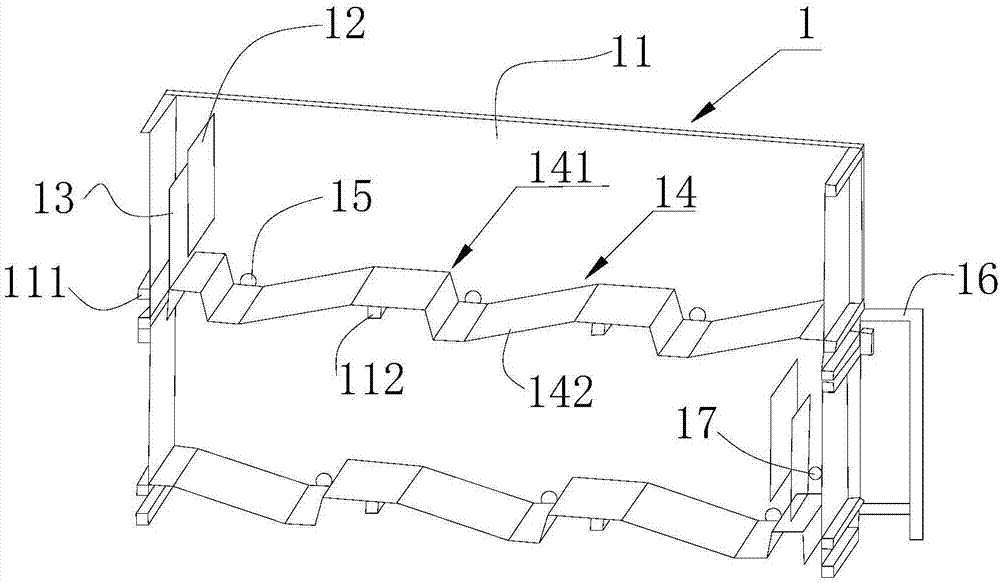

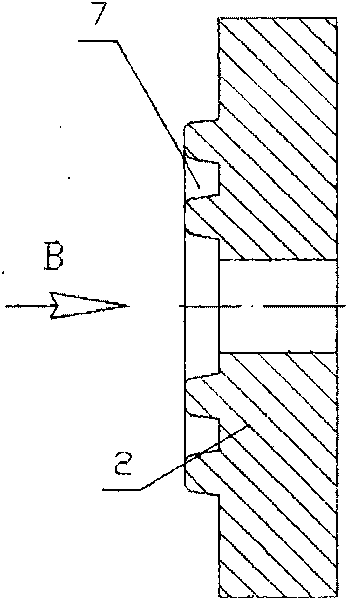

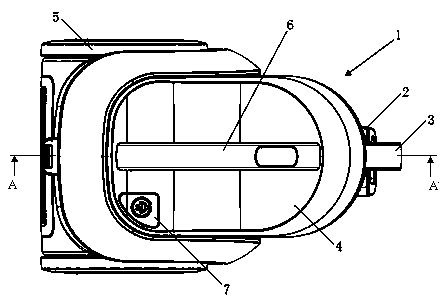

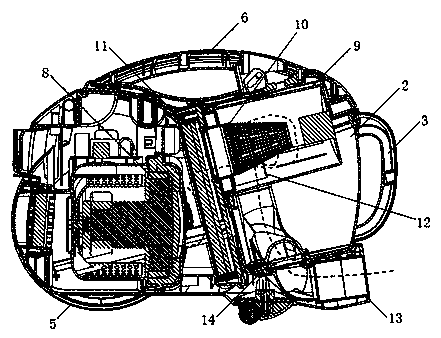

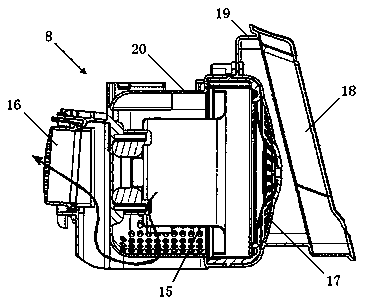

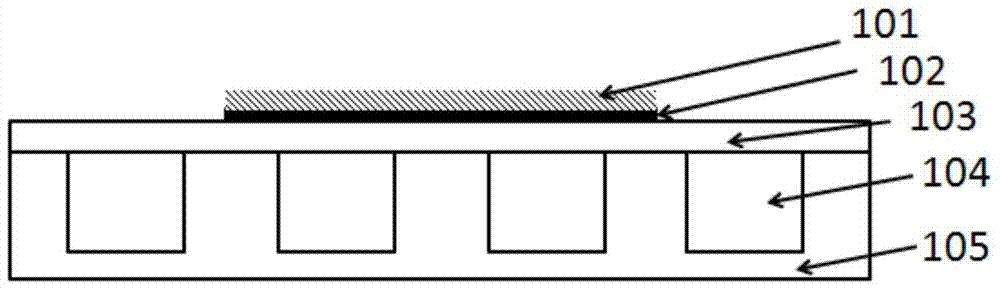

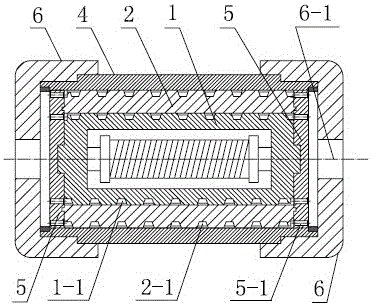

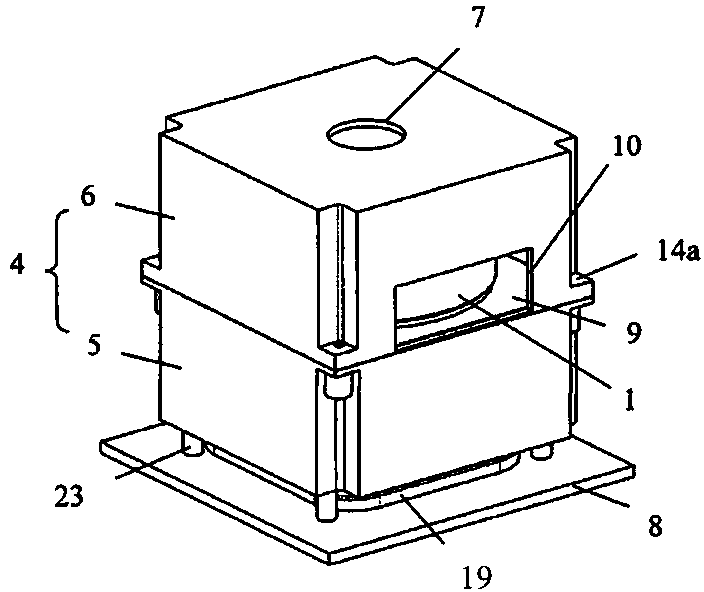

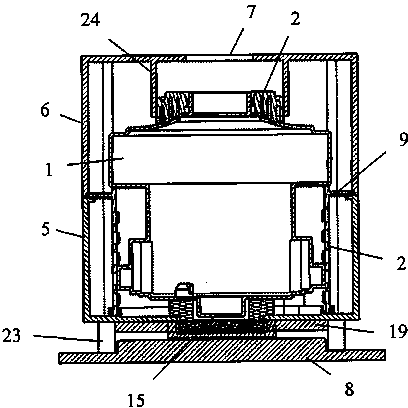

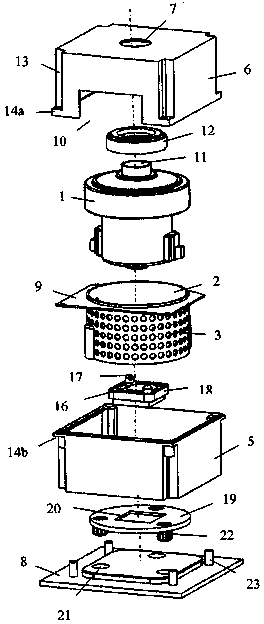

Layered runner motor shell of dust collector

InactiveCN102142732AIncrease the length of the runnerIncreased propagation lossSuction cleanersSupports/enclosures/casingsEngineeringMechanical equipment

The invention discloses a layered runner motor shell of a dust collector and belongs to electric mechanical equipment of the dust collector. The layered runner motor shell of the dust collector comprises inner shell bodies, square outer shells, outer shell air inlets and exhaust ports, wherein dust collection motors are respectively arranged in the inner shell bodies; the inner shell bodies are provided with vent holes; the square outer shells are arranged outside the inner shell bodies at certain spatial distance; each outer shell consists of an outer shell body and an outer shell cover; the outer shell air inlets are formed on the top of the corresponding outer shell covers; the exhaust ports are used for exhausting air from the outer shells; transverse clapboards for partly dividing the inside spaces of the outer shell are formed in the outer shells; the vent holes are formed on the peripheral walls of the inner shell bodies at the side that the center lines of the circle centers are passed through below the transverse clapboard so as to form lower clapboard channels and upper clapboard channels; and uplink runners and downlink runners are formed at the parts which are not divided by the transverse clapboards. By the layered runner motor shell adopting the design, the lengths of the runners for exhausting air are increased and the transmission loss of noise is improved, so that the noises generated when the motor shell of the dust collection exhausts the air are reduced.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

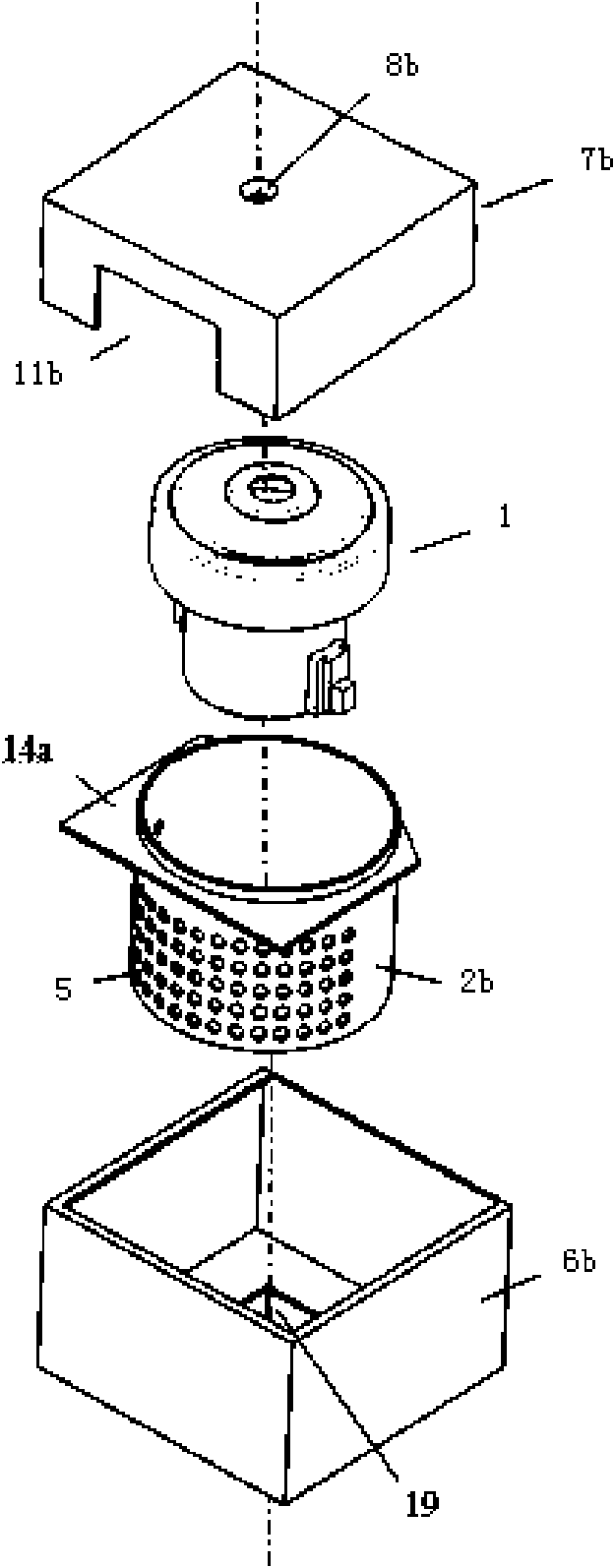

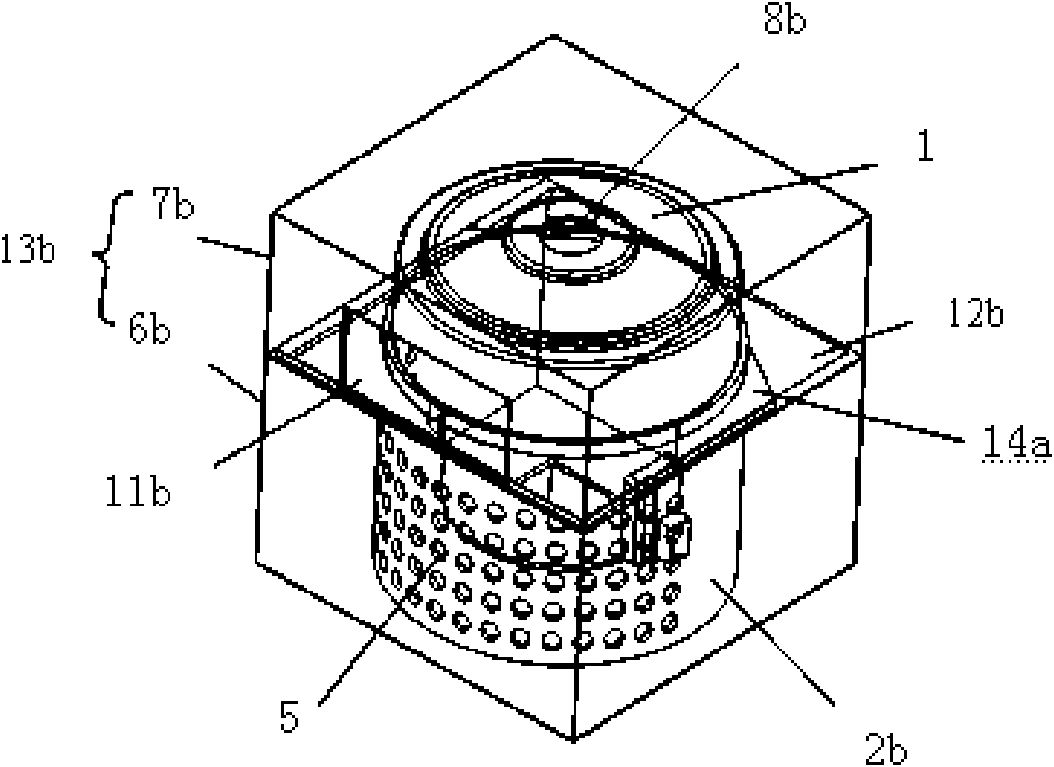

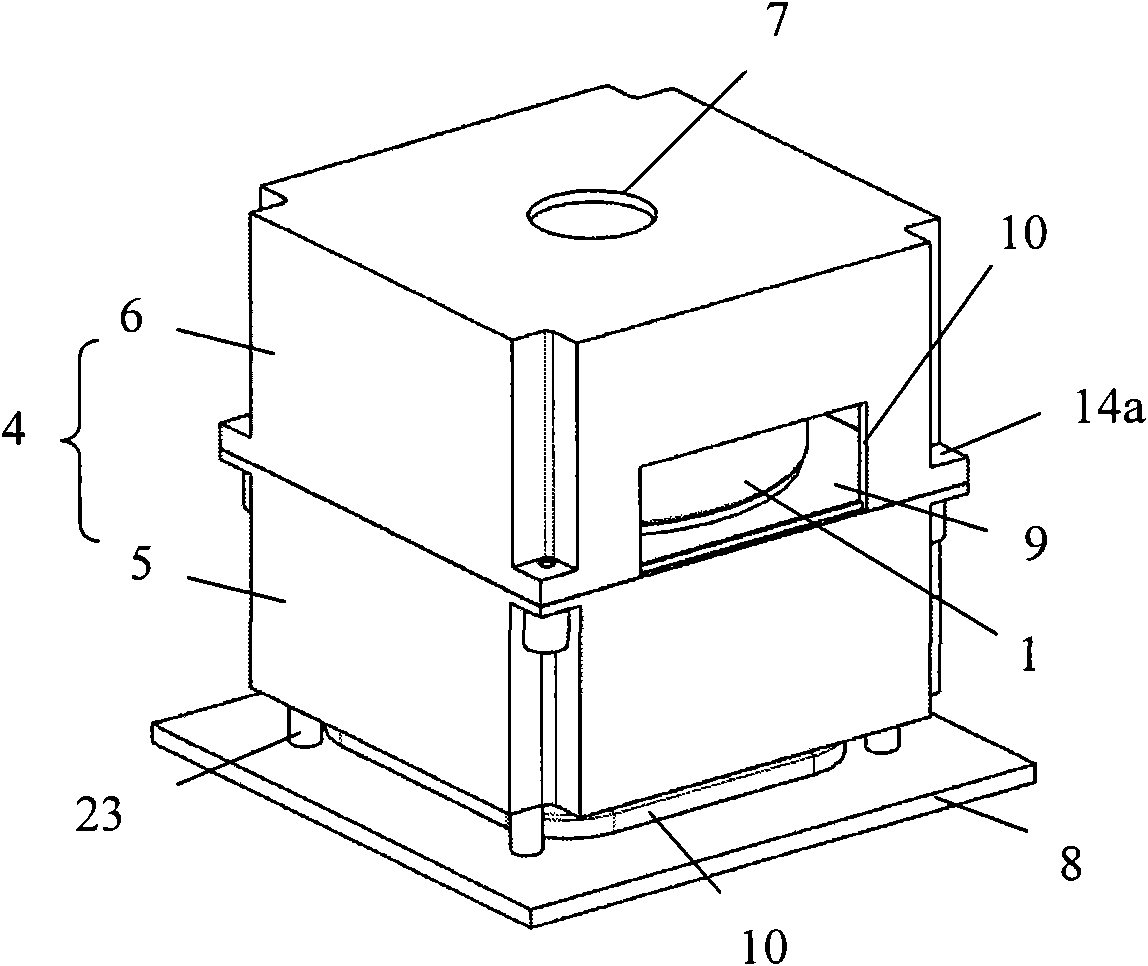

Motor casing with layered long flow channels

InactiveCN102377278AIncrease the length of the runnerReduce noiseSupports/enclosures/casingsInlet channelMechanical equipment

The invention discloses a motor casing with layered long flow channels, belonging to electrical mechanical equipment of a vacuum cleaner. The motor casing with layered long flow channels comprises a built-in vacuum motor, an inner casing with air holes, a square outer casing and an outer casing cover, wherein the inner casing is formed on one side; the square outer casing is arranged outside the inner casing and separated from the inner casing for a certain spatial distance; an air inlet is formed at the top of the outer casing cover and an air outlet is formed on one side of the outer casing cover; a lower-layer flow channel and an upper-layer flow channel are formed respectively in the outer casing and in the outer casing cover by a lateral partition; an up channel is formed on the lateral partition opposite to the air outlet in direction; an air inlet channel is formed between the air inlet of the outer casing and the air inlet of the motor; and a space dividing cover on which muffling holes are formed is arranged in the upper-layer flow channel on the periphery of the motor in the outer casing cover. Because the motor casing with layered long flow channels is designed such, based on the original double-layer motor casing with a long flow channel, the limited space in the upper-layer flow channel is fully used, and the space dividing cover with muffling holes is additionally arranged, thereby further increasing the length of the upper-layer flow channel and further reducing noise.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

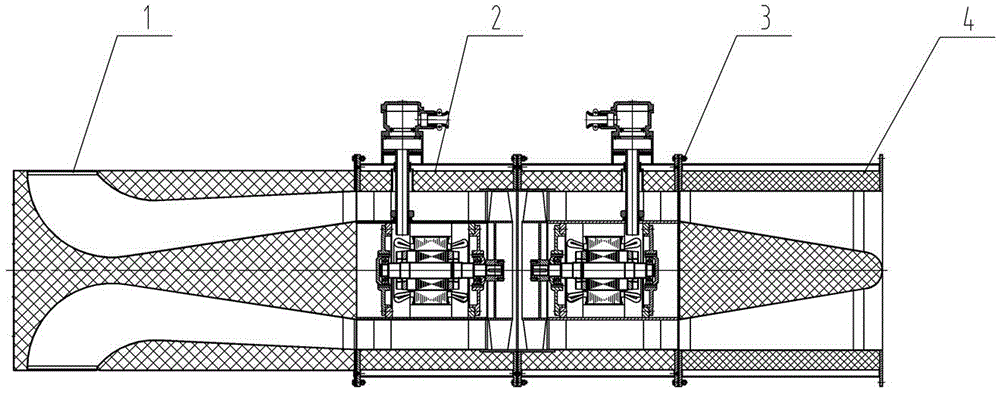

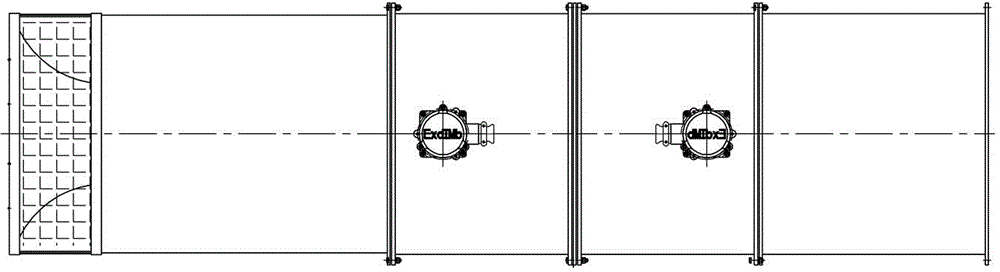

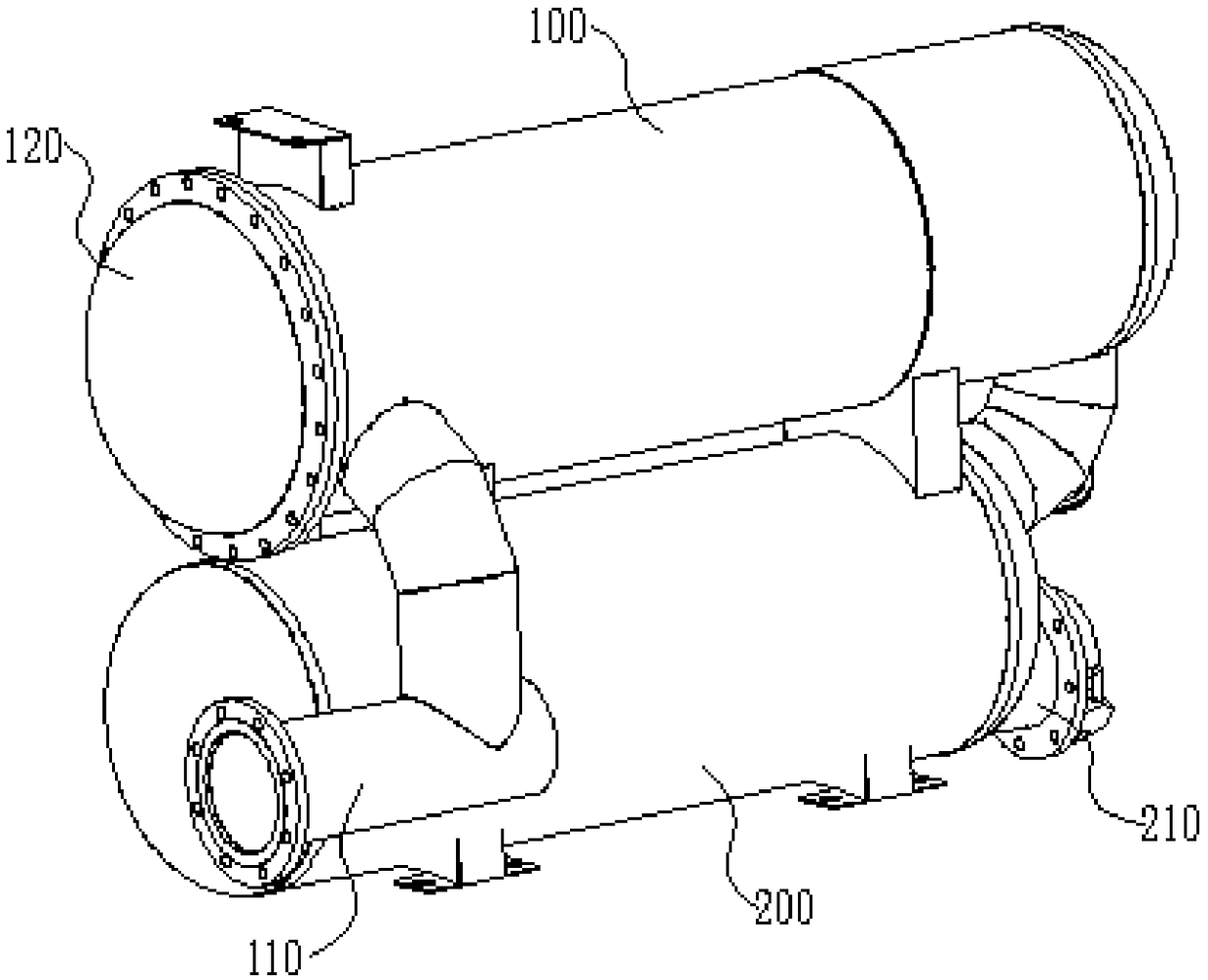

High-efficiency low-noise axial flow fan

InactiveCN104632714AReduce resistanceIncreasing the thicknessPump componentsPump installationsLow noiseImpeller

A high-efficiency low-noise axial flow fan mainly solves the technical problems that an existing axial flow fan is low in efficiency, high in noise and the like. According to the technical scheme, the high-efficiency low-noise axial flow fan is characterized by comprising a main fan body (2), a radial annular inlet (outlet) air muffler device (1) and a muffling diffusion cylinder (4), wherein the two ends of the main fan body (2) are connected with the radial annular inlet (outlet) air muffler device (1) and the muffling diffusion cylinder (4) respectively. A cylindrical housing (209) of the main fan body (2) and a motor housing (215) form an airflow passage. The inner wall of the motor shell (215) is provided with an axial rib plate or a fan-shaped block to support a stator (205). The outer diameter of the motor housing (215) is consistent with the diameter of a hub of an impeller (216), the diameter of an inner cylinder of a front muffler and the diameter of an inner cylinder of a rear muffler. The two ends of the motor housing (215) are basically flush with one end of a main fan body housing. A flange fixing a rotator and an end cover are arranged on the inner side of the motor housing (215). Accordingly, resistance loss is reduced. An air inlet (outlet) flow passage is designed to be of a gradual-shrinkage structure and a gradual-expansion structure, so aerodynamic performance and efficiency are improved; by the adoption of the radial annular inlet (outlet) air muffler device and the main fan body housing muffling structure combining multiple mechanisms, the purpose of noise reduction is achieved. The high-efficiency low-noise axial flow fan can be widely applied to ventilation on various occasions such as mines, tunnels, industries and enterprises.

Owner:PINGAN ELECTRICAL

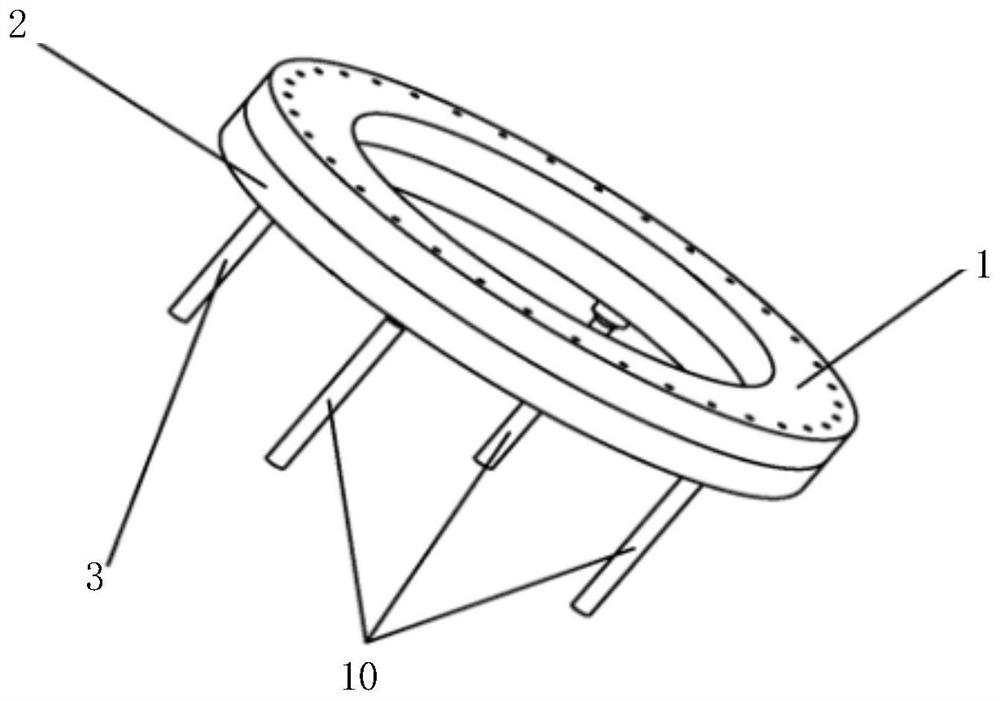

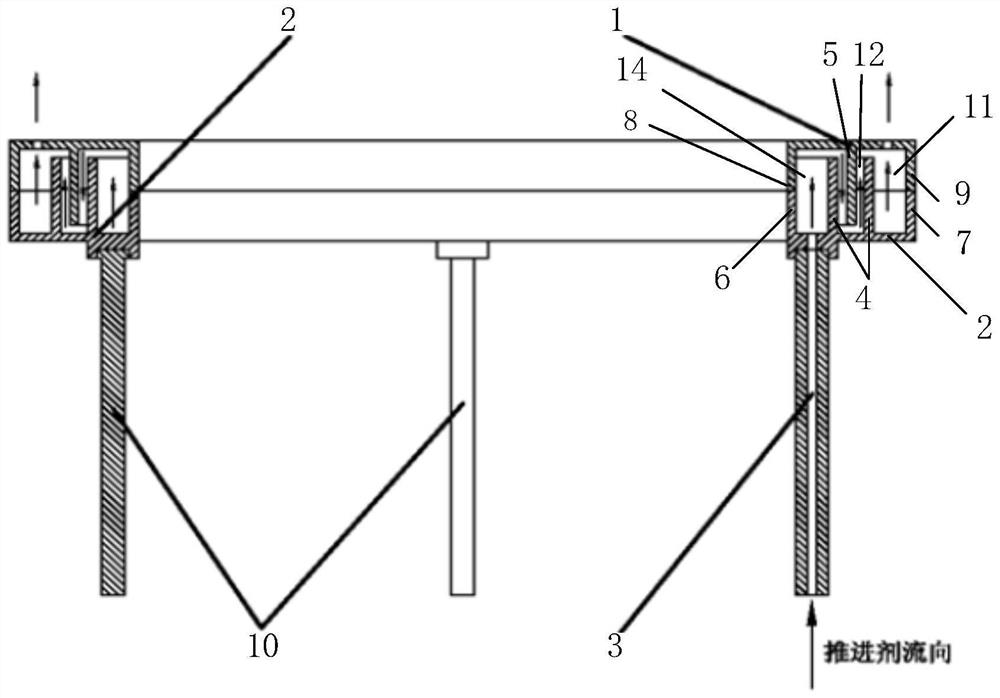

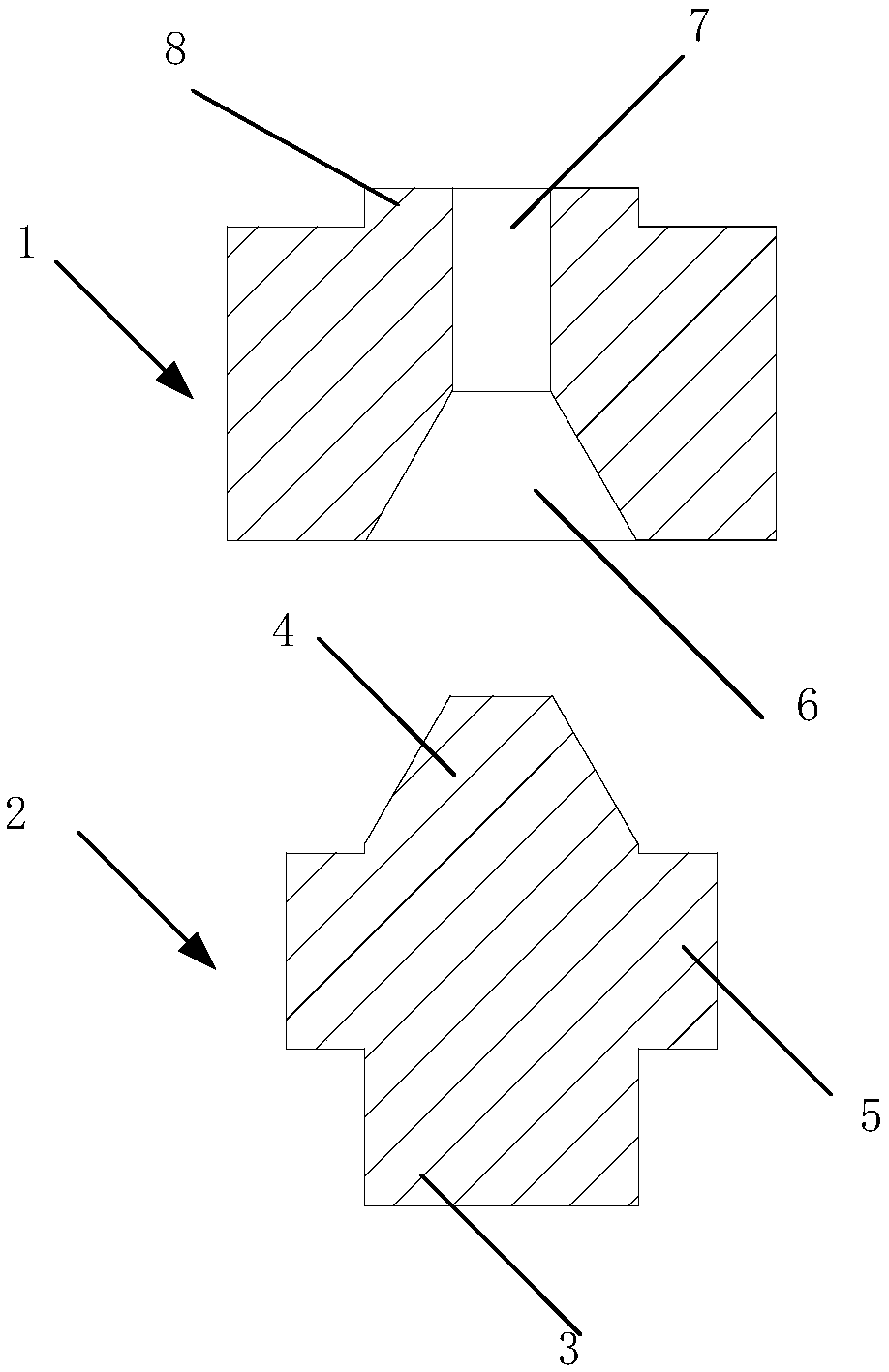

Gas distributor

PendingCN114352831AIncrease the length of the runnerExtend the homogenization timeMachines/enginesPipeline systemsDistributorMechanics

The invention provides a gas distributor. The gas distributor comprises a top structure, a bottom structure and a gas pipe, the bottom structure comprises a bottom plate, a first partition plate, a first inner wall and a first outer wall; the bottom end of the bottom plate is communicated with the air pipe; the top structure comprises a top plate, a second partition plate, a second inner wall and a second outer wall; a vent hole is formed in the top end of the top plate; the top structure is installed on the bottom structure, the top end of the first inner wall is connected with the bottom end of the second inner wall, and the top end of the first outer wall is connected with the bottom end of the second outer wall; the first partition plate and the second partition plate are arranged in a spaced mode. The radial flow homogenization mode of the gas working medium is adopted, the flow channel length of the gas working medium in the gas distributor can be greatly increased through the combination of the homogenization flow channels and the partition plates, the homogenization time of the gas working medium is prolonged, and therefore the working medium gas is better homogenized before entering a discharge channel of the Hall thruster.

Owner:SHANGHAI INST OF SPACE PROPULSION

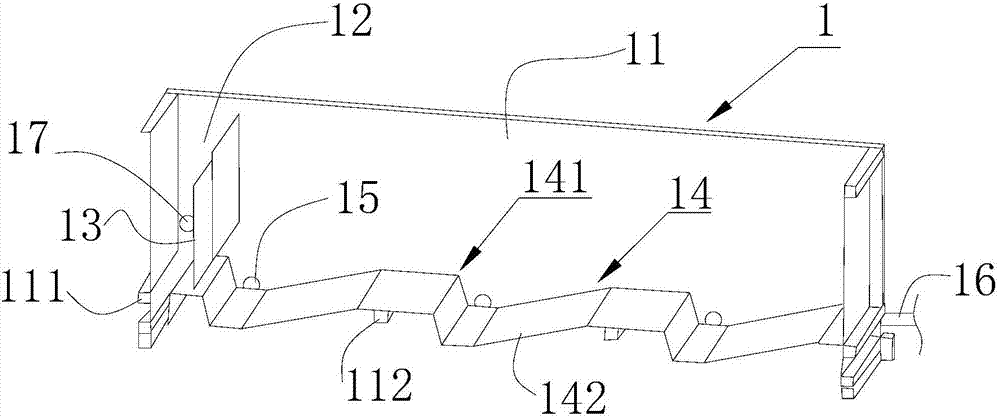

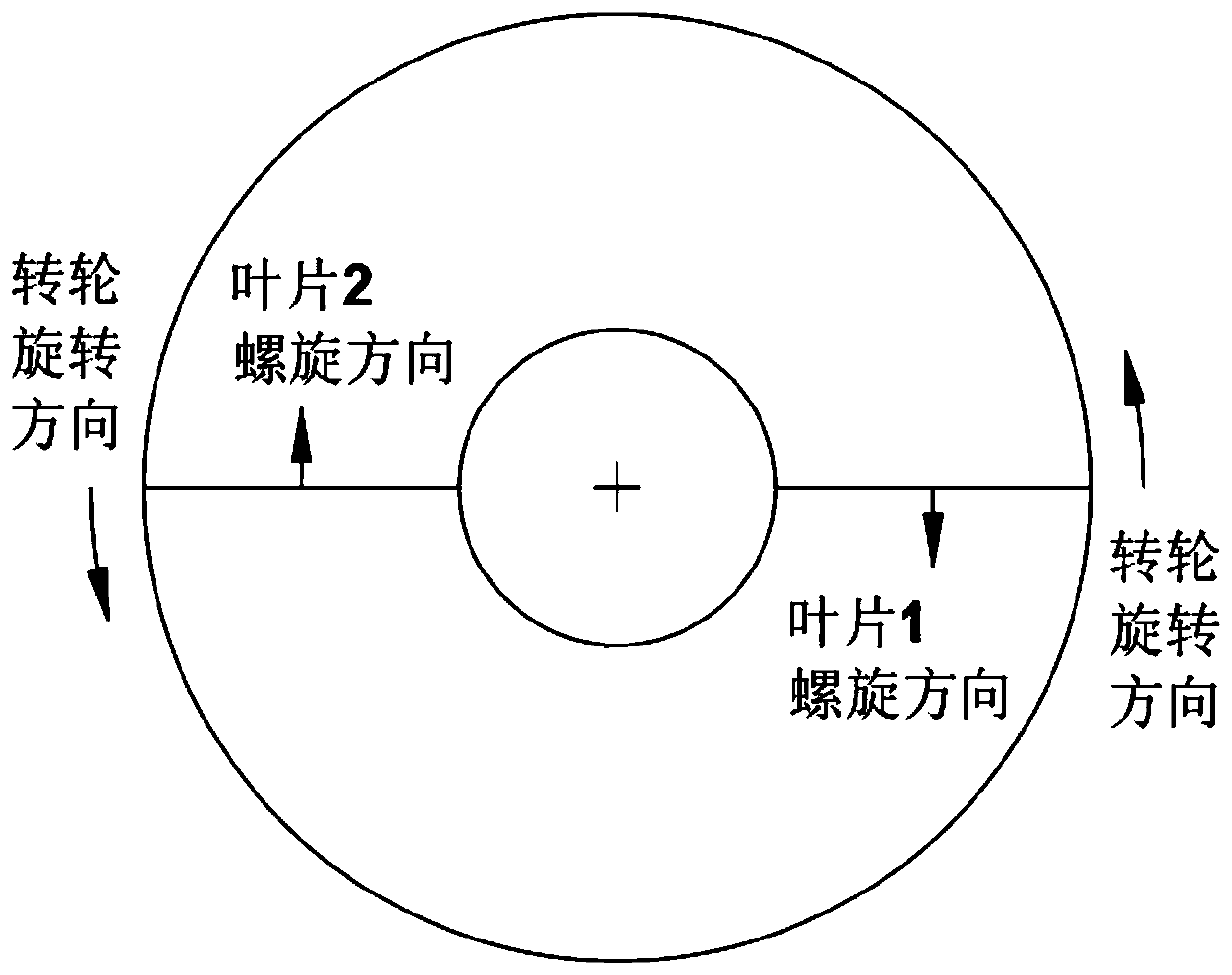

Stacked overflow type sewage treatment equipment

PendingCN107265668AEasy to assembleIncrease total water flow capacitySettling tanks feed/dischargeTreatment involving sedimentationSewage outfallWater flow

The invention discloses stacked overflow type sewage treatment equipment which comprises a plurality of stacked cases. The stacked cases are assembled to form the stacked overflow type sewage treatment equipment and comprise cases, first barriers, overflow plates, settling tanks and pollution discharge pipes, the first barriers and the overflow plates are longitudinally parallelly arranged on the inner walls of the cases, and one end of each settling tank is fixedly connected with the corresponding overflow plate so that a cavity can be formed by each settling tank and the corresponding case; the other end of each settling tank is connected with a side wall of the corresponding case, a water outlet is formed in the inner wall of each case, a plurality of pollution discharge outlets are formed in joints of the settling tanks and the inner walls of the cases, and the pollution discharge pipes are arranged on the outer sides of the cases and are communicated with the pollution discharge outlets. The stacked overflow type sewage treatment equipment has the advantages that the quantities of the stacked cases can be set as needed, the stacked cases are assembled in a stacked manner, and accordingly the problem of excessively high side pressures can be solved; the stacked cases are connected with one another in a multilevel manner, accordingly, the lengths of water flow channels can be increased, the total capacity can be increased, and overflow type merits can be effectively utilized by the stacked overflow type sewage treatment equipment; the stacked cases of the stacked overflow type sewage treatment equipment can be assembled as needed, the volume of the stacked overflow type sewage treatment equipment can be voluntarily adjusted, and the stacked cases are convenient to assemble.

Owner:GUANGZHOU LAIRUI WATER TREATMENT TECH

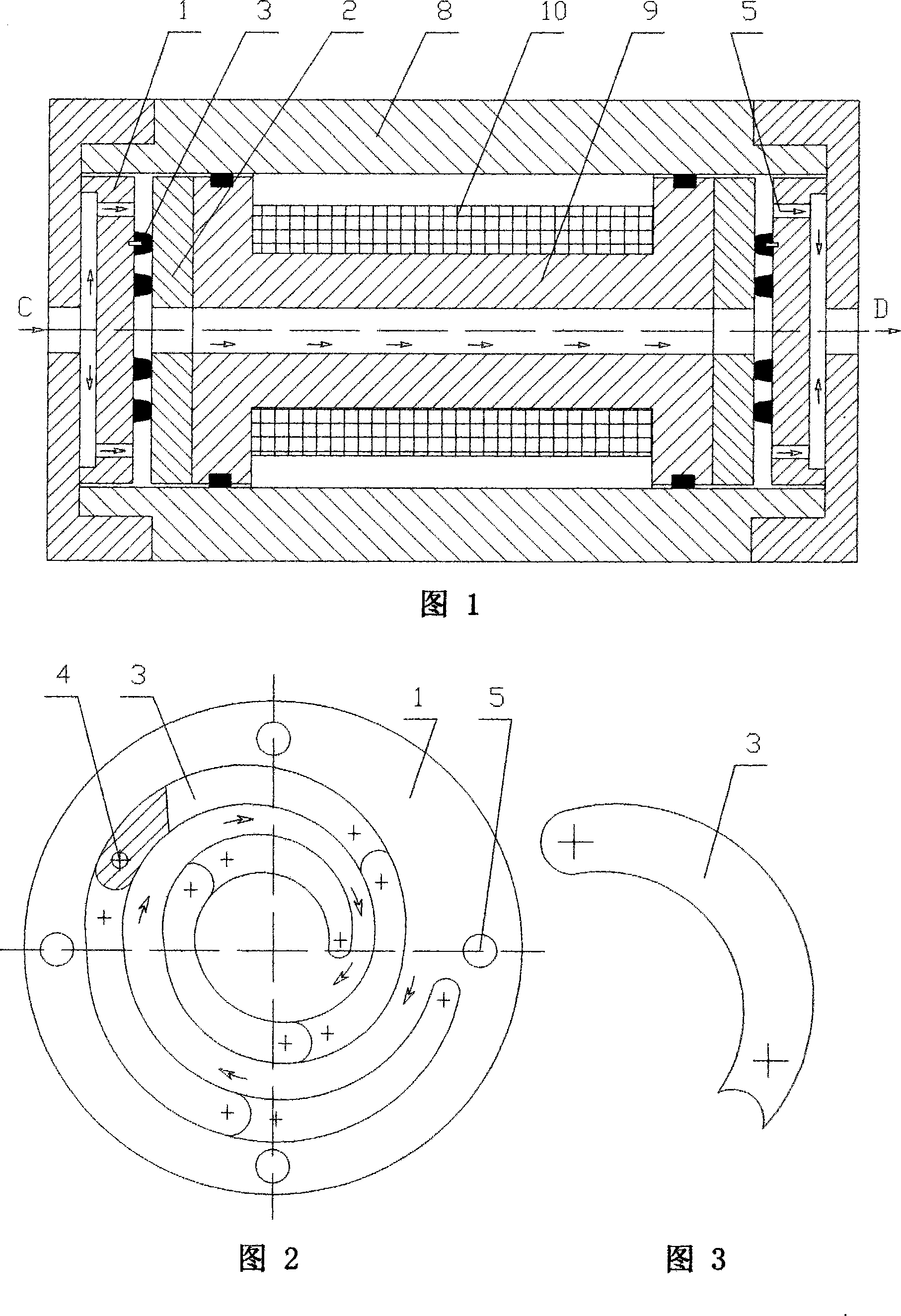

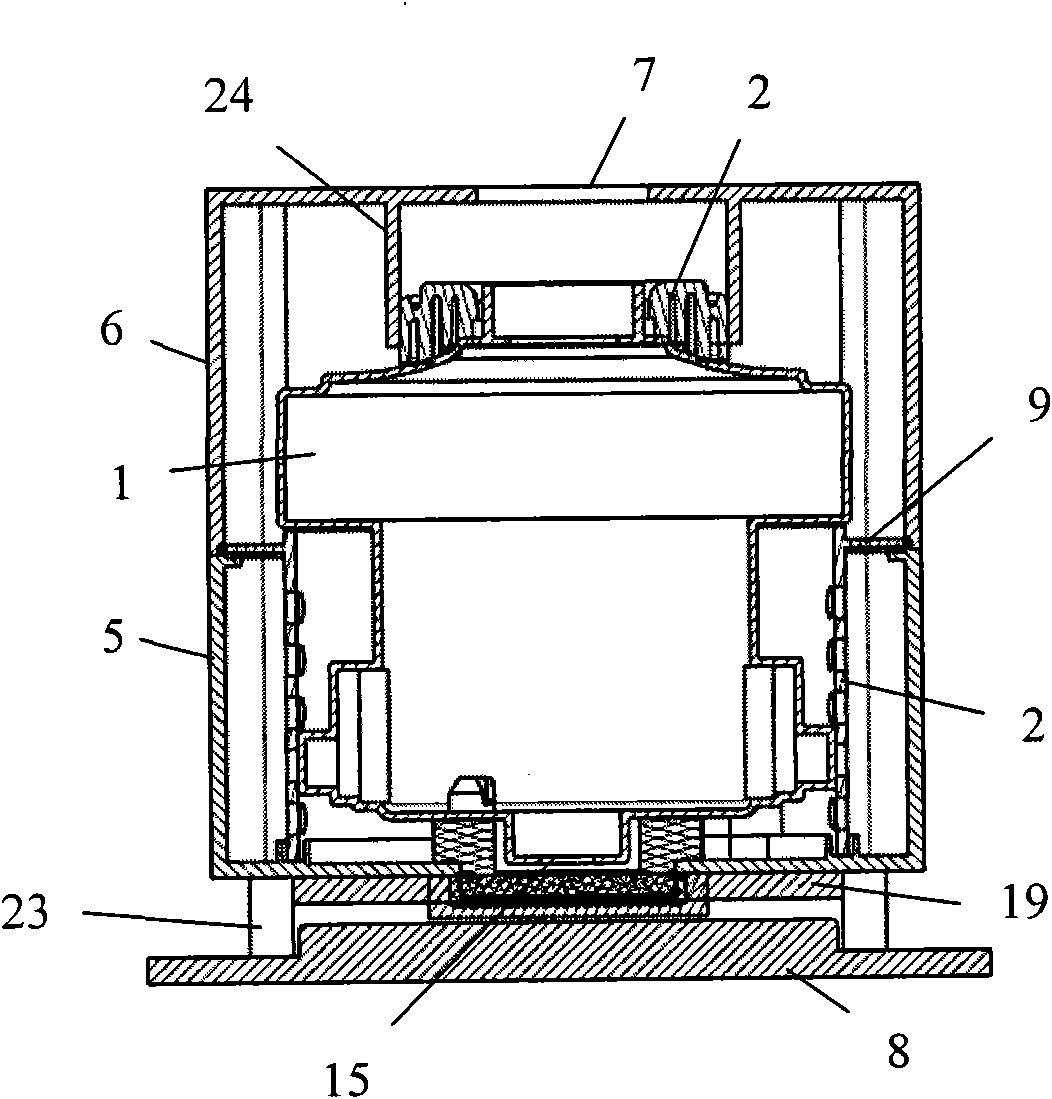

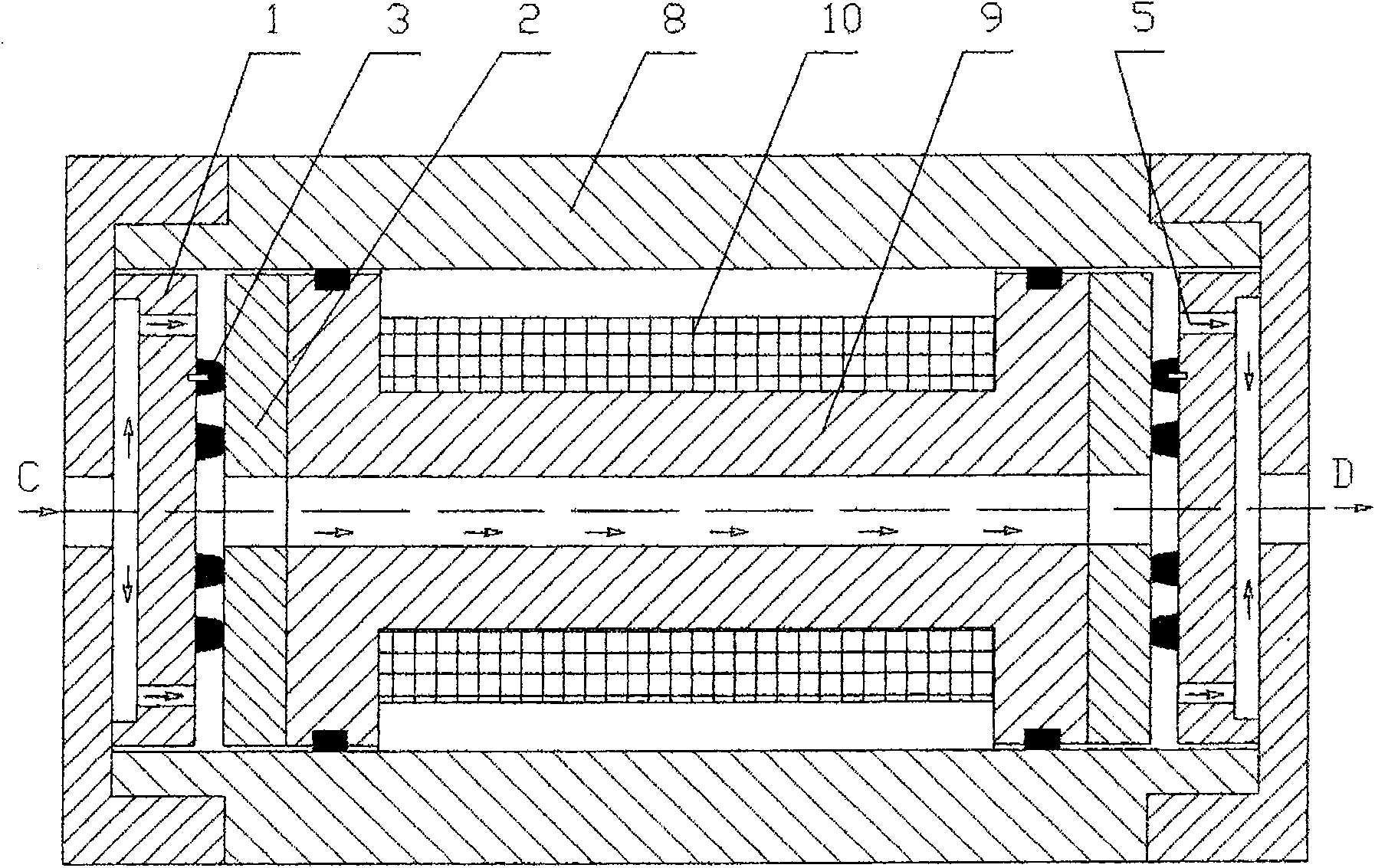

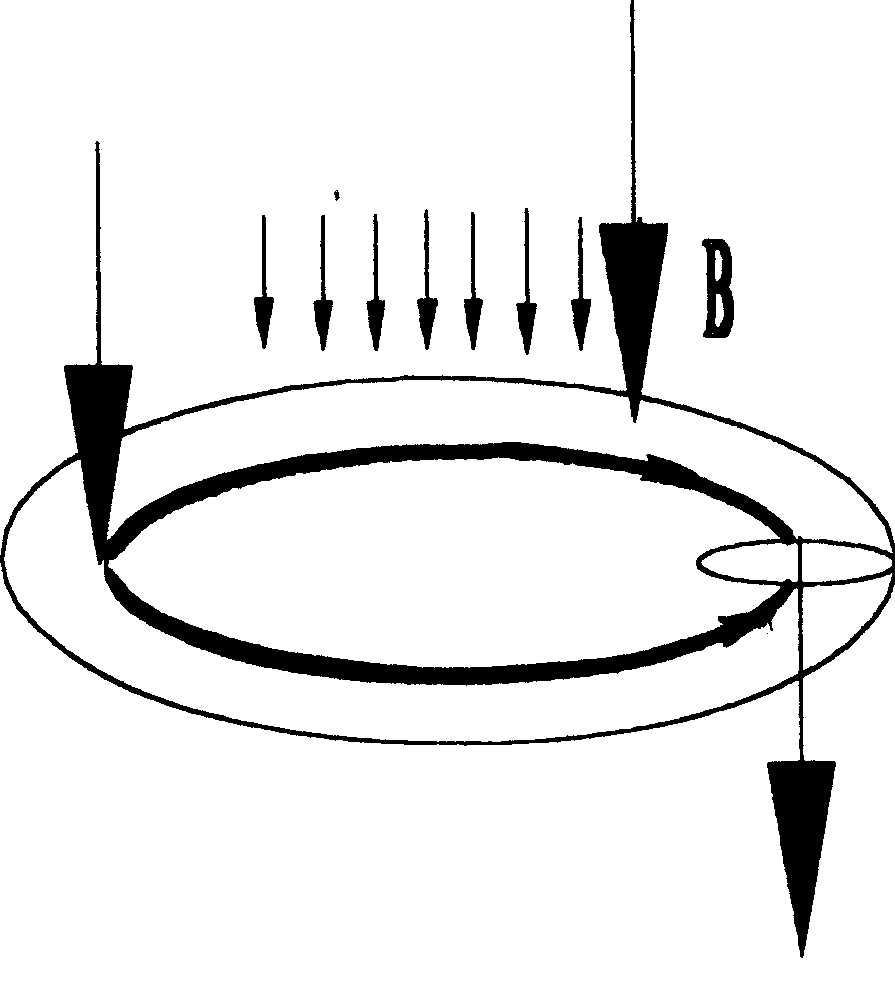

MR valve of non-rectilinear fluid course

InactiveCN101265929BSimple structureEasy to manufacture and installNon-rotating vibration suppressionFluid dynamicsPath lengthMagnetorheological fluid

A MRF valve for non-linear flow channel mainly solves the problem that the magneto-rheological fluid conducts non-linear flow along the flow channel in the MRF valve. The MRF valve prolongs the flowing path length of the magneto-rheological fluid, improves the utilization rate of the magnetic line and increases the pressure difference of the controllable fluid of the magneto-rheological fluid under the same current intensity, thus achieving the aim of saving energy and reducing the size of the MRF valve. The technical scheme is to arrange a non-linear flow channel on the corresponding end surface of a positioning plate and a magnetic conductive disk. The MRF valve has advantages of simple structure, convenient manufacture and installation; the control range of the MRF valve is expanded without increasing the size of the MRF valve.

Owner:黑龙江科大科技开发有限公司

Low-noise motor casing structure with crossed flow channel of vacuum cleaner

The invention discloses a low-noise motor casing structure with a crossed flow channel of a vacuum cleaner. The low-noise motor casing structure comprises an inner shell and an outer shell, wherein a dust collecting motor is arranged in the inner shell, the outer shell is arranged outside the inner shell at a certain spatial distance, an air inlet of the outer shell is formed in the front end of the outer shell, the crossed flow channel is formed between the outer shell and the inner shell, air outlets of the inner shell are formed in the peripheral wall of the inner shell, and air outlets of the outer shell are formed in the tail end of the outer shell. When the vacuum cleaner is operated, air flow which flows through a motor is exhausted through the two air outlets in the inner shell and propagated through the crossed flow channel, after the air flow reaches a diversion baffle, the air flow is shunted and propagated to the air outlets of the outer shell above and below the diversion baffle through diversion ribs, and finally, the air flow is exhausted. By using such a motor casing structure, the length of the flow channel for exhausting the air flow is increased and maximized within limited space, the purpose of reducing noise is realized by increasing the propagation loss of the noise, and the motor casing structure has the advantages of low cost, simplicity and easiness in realization.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Magnetorheological valve of helical fluid channel

InactiveCN100587277CSimple structureEasy to manufacture and installNon-rotating vibration suppressionFluid dynamicsPath lengthNonlinear flow

The invention provides a magneto-rheological fluid (MRF) valve of a spiral liquid passage, which mainly solves the problem of nonlinear flow of the MRF along the liquid passage in the MRF valve, enlarges the flowing path length of the electro-magneto-rheological fluid, improves the utilization ratio of the line of magnetic force, improves the pressure difference of the controllable fluid of the electro-magneto-rheological fluid under the equivalent current intensity and unchangeable magnetic gap, and achieves the objects of saving energy and reducing the dimension of the MRF valve. The proposal of the MRF valve is that the corresponding end surface of a positioning disc to a magnetic guide disc is provided with a nonlinear liquid passage. The MRF valve has the advantages of simple structure of MRF valve, convenient manufacture and installation, increasing no volumes of the MRF valve, and enlarging the control range of the MRF valve.

Owner:黑龙江科大科技开发有限公司

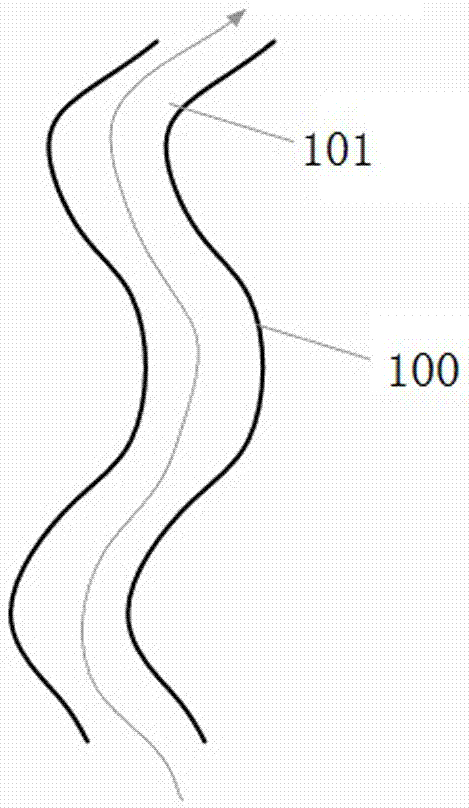

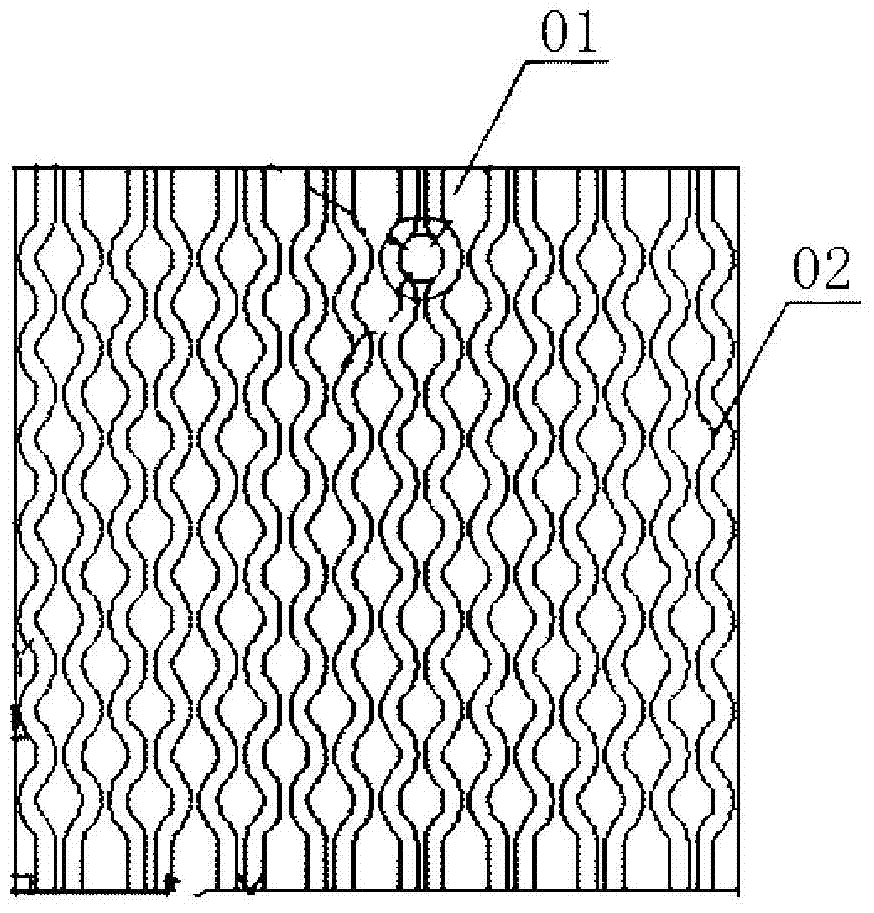

Curved-surface plate and flow channel bending device using curved-surface plate

InactiveCN107051248AEnhanced spoiler abilityIncrease the length of the runnerFlow mixersTransportation and packagingInteraction deviceEngineering

The invention relates to the field of fluid interaction devices, in particular to a curved-surface plate and a flow channel bending device using the curved-surface plate. The curved-surface plate is provided with a spiral groove, the spiral groove is provided with a datum line, the datum line is cylindrical spiral line, and the wall face of the spiral groove is a curved surface for passing after the datum line performs translation according to a set trajectory. Compared with the flow channel bending device which can only make a fluid disturbed in one plane. When the curved-surface plate is used and the fluid passes through the spiral groove, a rotational flow can be formed in a space, the disturbing capability of the fluid can be enhanced, and meanwhile the length of a flow channel can be prolonged. The problem that an existing flow channel bending device has small fluid disturbance and accordingly low heat exchange efficiency, poor mixing effect and the like are caused is solved.

Owner:苏跃进

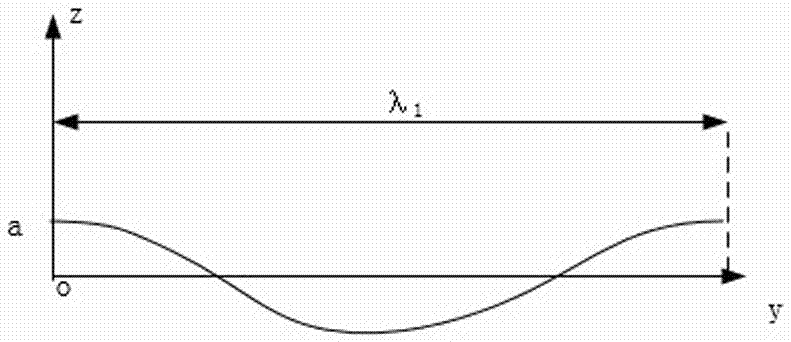

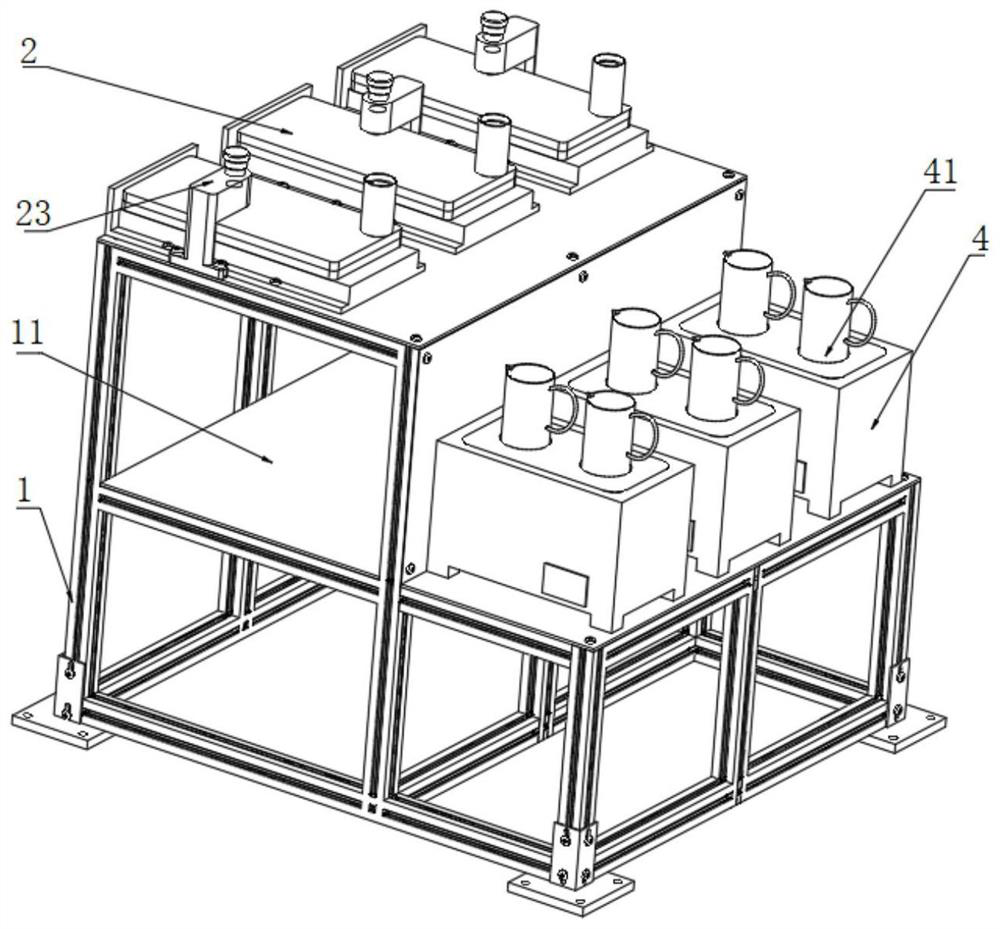

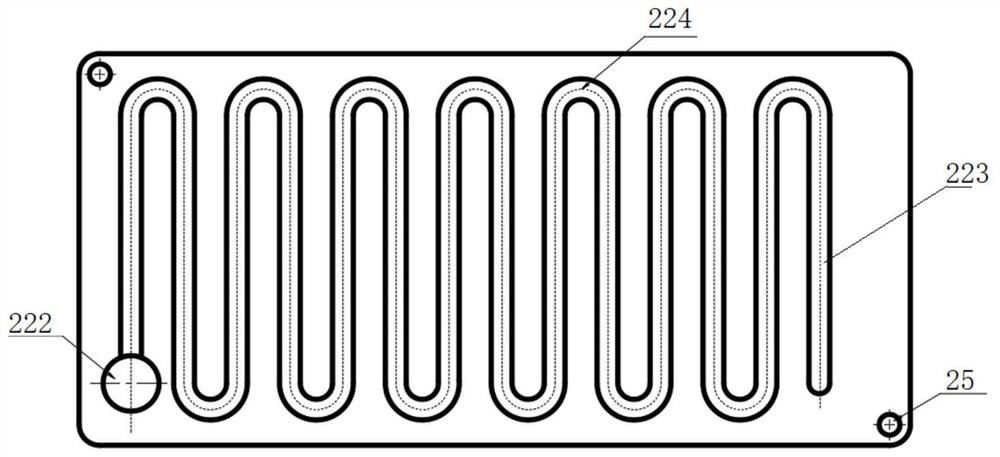

Fluidity measuring device and measuring method based on serpentine flow channel

PendingCN111781101AEasy to observeIncrease the length of the runnerEducational modelsDirect flow property measurementEngineeringMechanical engineering

The invention provides a fluidity measuring device and measuring method based on a serpentine flow channel. The device comprises: at least one mold assembly, which is arranged on a rack, and comprisesan upper mold plate and a lower mold plate, wherein the upper mold plate is arranged on the lower mold plate, the serpentine flow channel is formed in the face, close to the upper mold plate, of thelower mold plate, a flow channel opening is formed in the upper mold plate, and the flow channel opening is communicated with a pouring inlet of the serpentine flow channel; a pouring cup, which is arranged on the upper mold plate, is communicated with the pouring inlet through the flow channel opening; and a heating device, which is arranged on the rack. According to the fluidity measuring deviceand measuring method based on the serpentine flow channel, a straight flow channel is changed into the serpentine flow channel, the length of the flow channel is increased under the condition that the size of the mold assembly is not changed, the upper mold plate is made of a transparent material, and the experiment phenomenon can be conveniently observed in the testing process.

Owner:NANTONG UNIVERSITY

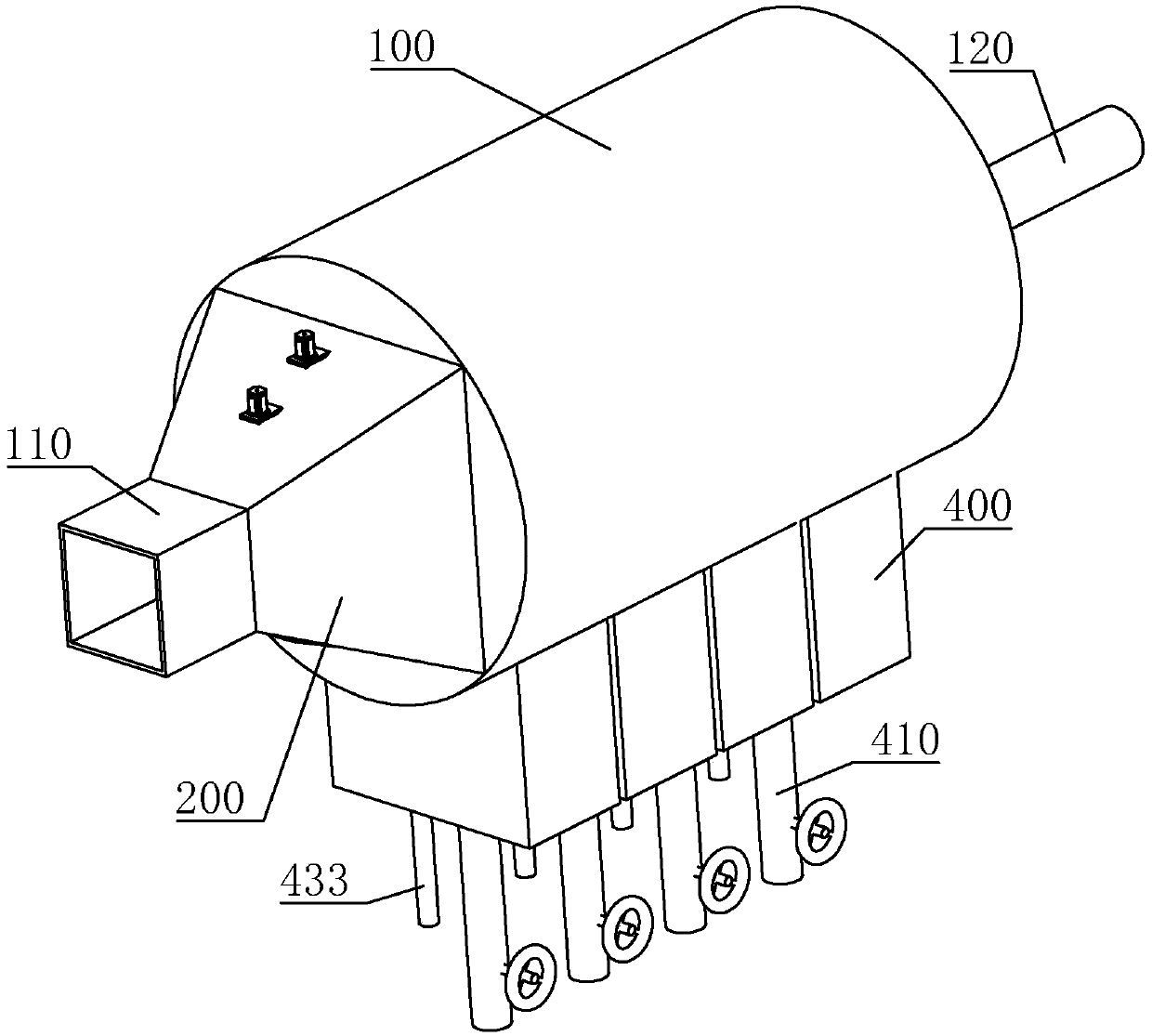

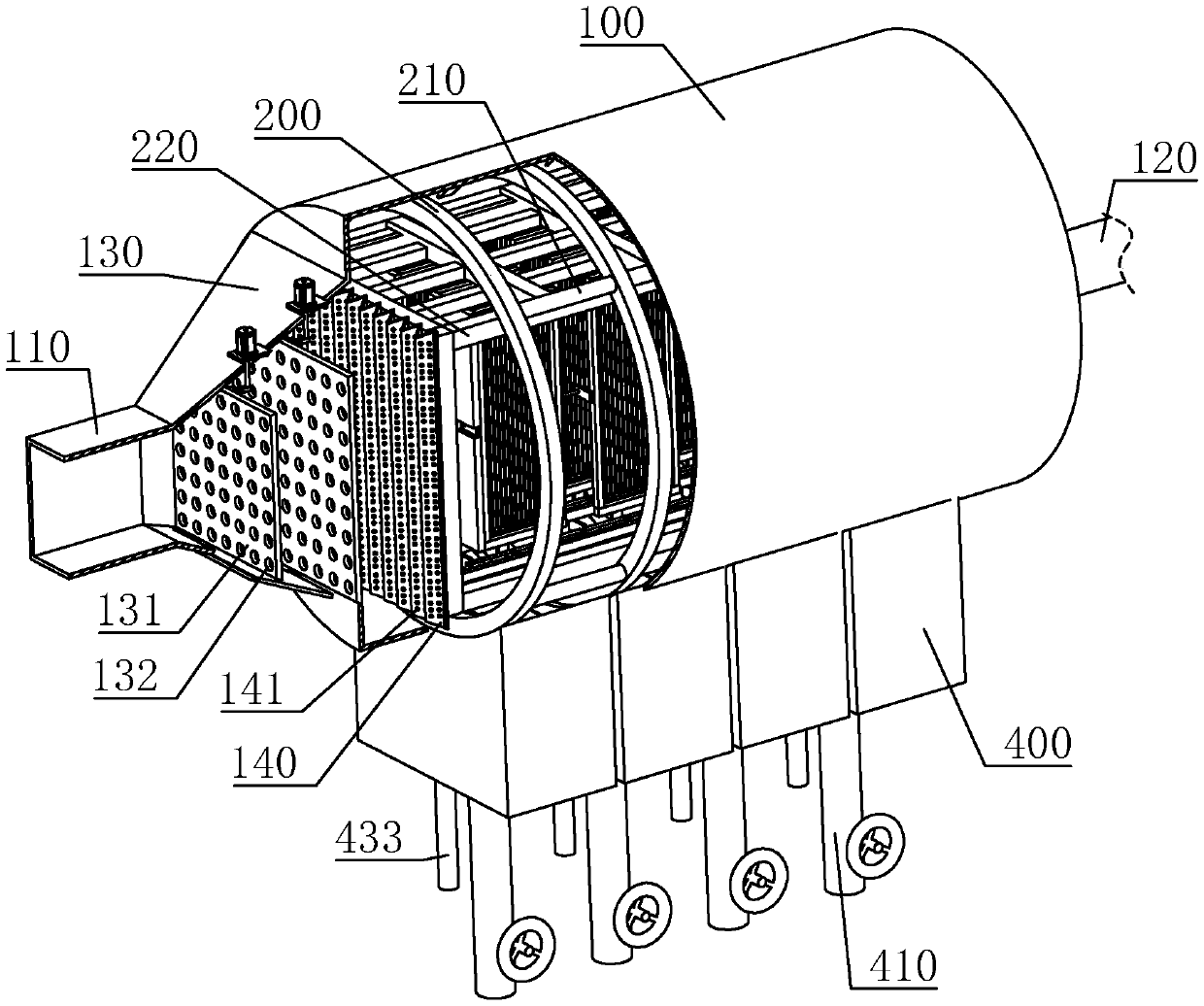

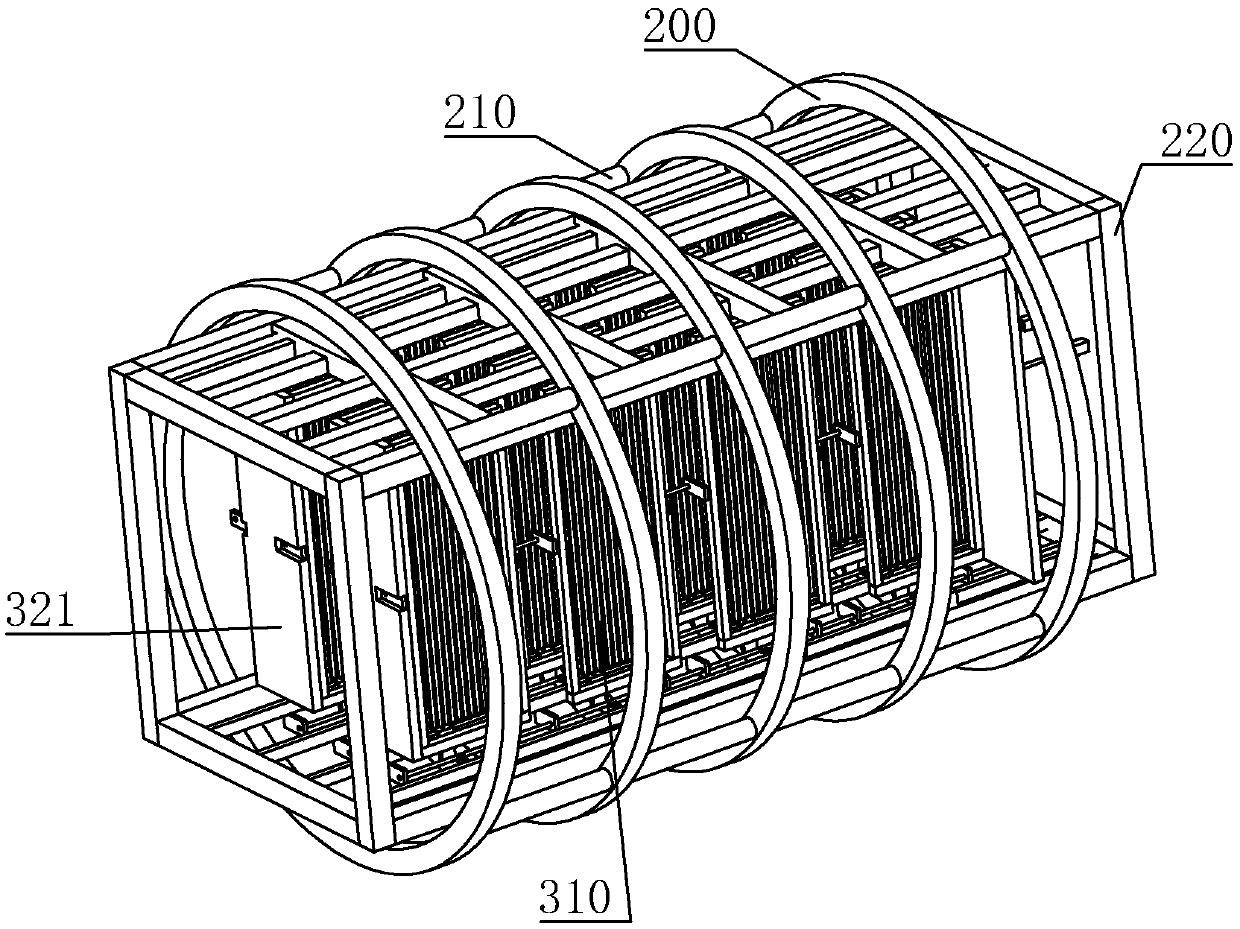

Coulomb electrostatic precipitator

ActiveCN109647623AImprove support strengthHigh strengthFireproof paintsElectrode carrying meansWhole bodyEngineering

The invention relates to the technical field of a dust removing device, and relates to a Coulomb electrostatic precipitator. The Coulomb electrostatic precipitator comprises a housing body, an air inlet pipe and an air outlet pipe, wherein the air inlet pipe and the air outlet pipe are respectively arranged at two ends of the housing body. A plurality of ring beams abutted against the inner wall of the housing body are arranged in the length direction in the housing body. The ring beams are connected with each other through connecting rods, and a framework having a rectangular cross section which is internally connected with the ring beams is arranged in the housing body. A dust removing device is arranged on the framework and comprises anode plates arranged on the framework and cathode wires arranged on the framework. The anode plates and the cathode wires are arranged in the housing body in a rectangular array manner. The Coulomb electrostatic precipitator has the following effects:the ring beams can support the housing body to a certain extent; the connecting rods connect all the ring beams into a whole body; the framework internally connected to the ring beams can further increase the overall strength of the housing body; and the framework is capable of carrying out secondary support on the ring breams, so the possibility of heat deformation of the housing body during treatment of high temperature smoke is reduced, and the service life of the device is prolonged.

Owner:ZHUJI KULUN ENVIRONMENTAL TECH CO LTD

Anti-creeping water pipe connector and water heater with same

PendingCN109282498AIncrease the cross-sectional areaIncrease resistanceFluid heatersEngineeringBathing water

The invention discloses an anti-creeping water pipe connector arranged outside an inner container of an electric water heater. The anti-creeping water pipe connector comprises a connector body, a hotwater runner and a cold water runner, wherein the hot water runner and the cold water runner are arranged in the connector body; the connector body is made of an insulating material; a water inlet connector and a water outlet connector are formed on the lower end face of the connector body; a water inlet and a water outlet are formed in the upper end face of the connector body; the water inlet connector and the water inlet communicate through the cold water runner; the water outlet connector and the water outlet communicate through the hot water runner; cold water is injected into the inner container through the water inlet connector via the cold water runner and the water inlet; and hot water of the inner container is guided out to a bathing water pipe through the water outlet connector via the water outlet and the hot water runner. By means of the reciprocating type runner design and the flexible runner section shape design, the space size can be fully utilized, the cross sectional area of the runners is effectively enlarged, the length of the runners is prolonged, electric resistance of a water path is increased under high flow, and the anti-blocking and anti-creeping propertiesare improved. The invention further discloses the water heater with the anti-creeping water pipe connector.

Owner:GUANGDONG GEMAKE ELECTRIC APPLIANCE

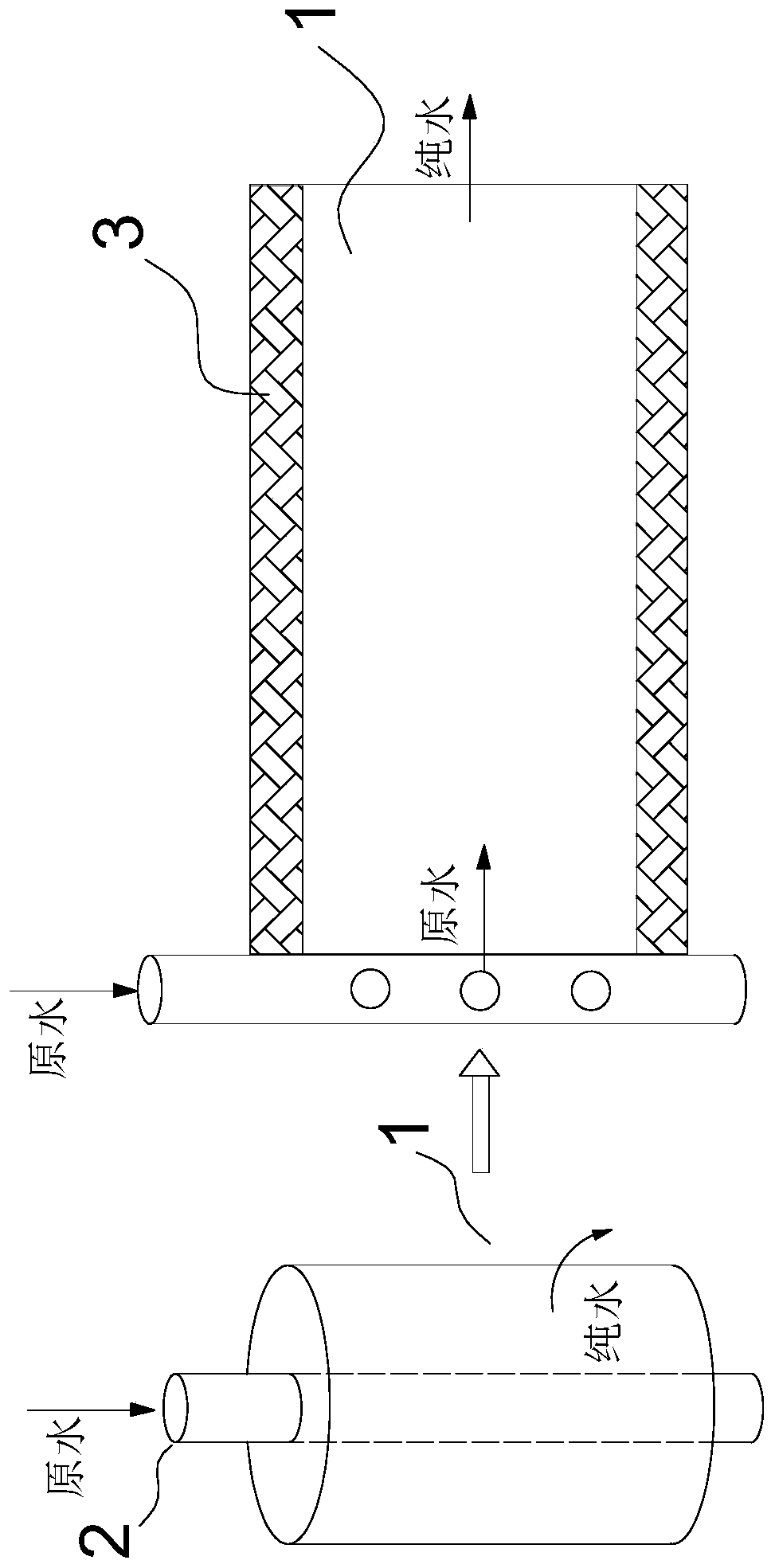

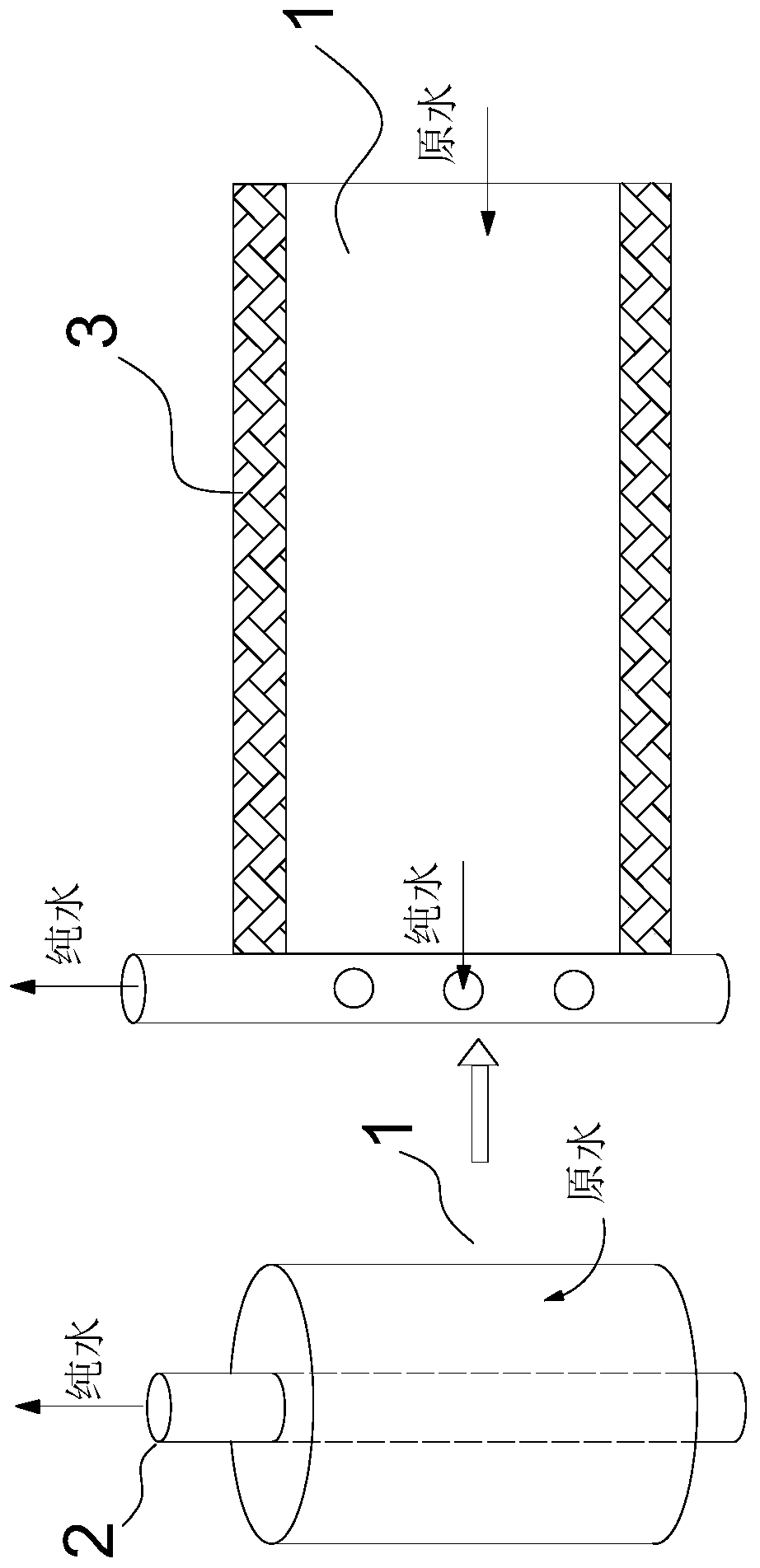

Capacitive desalination filter element and water treatment device provided with filter element

PendingCN110759438AExtend your lifeSimple structureDispersed particle separationWater/sewage treatmentDesalinationProcess engineering

The invention discloses a capacitive desalination filter element. The capacitive desalination filter element is provided with a capacitive desalination unit, wherein a flow passage for flowing of rawwater is arranged inside the capacitive desalination unit, the length of the raw water in the capacitive desalination unit is defined as A, the width of the capacitive desalination unit is defined asB, and A and B meet the relation that A>B>0. According to the capacitive desalination filter element, the length of the flow passage of the raw water in the capacitive desalination unit is increased under the situation of not changing the volume, so that the desalination effect is improved; and meanwhile, since the volume of the capacitive desalination filter element is not changed and the lengthof the flow passage is increased, the flow velocity of the raw water inside the capacitive desalination unit is increased, a double-electrode layer can be lowered, desalination efficiency can be improved, anti-pollution performance can be improved, and the life of the capacitive desalination filter element can be prolonged. A water treatment device is provided with the capacitive desalination filter element and a shell. The water treatment device has the advantages of being simple in structure, small in size, free of noise and free of pressure increase and can be directly assembled to a faucet.

Owner:GUANGDONG LIZI TECH CO LTD

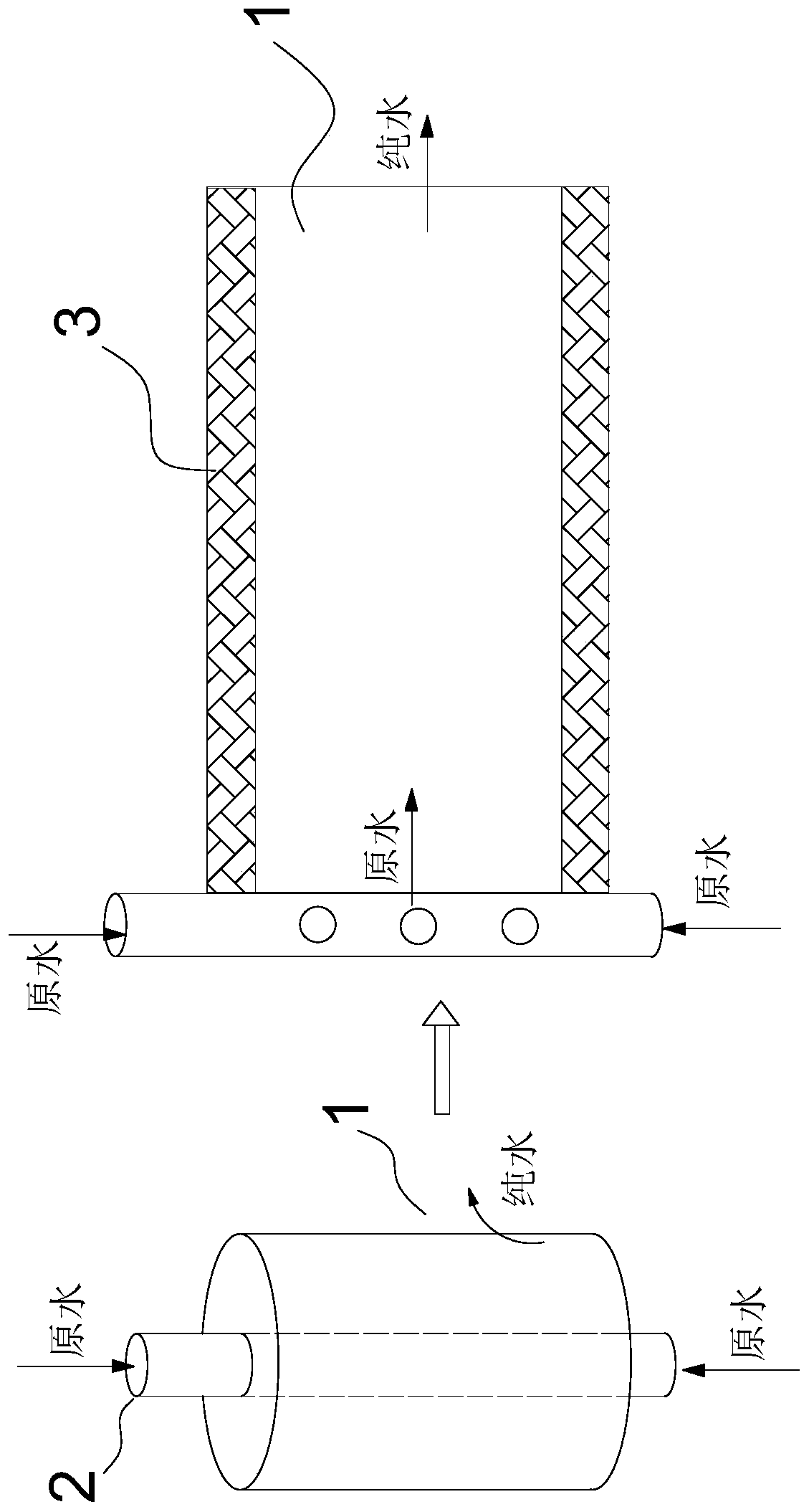

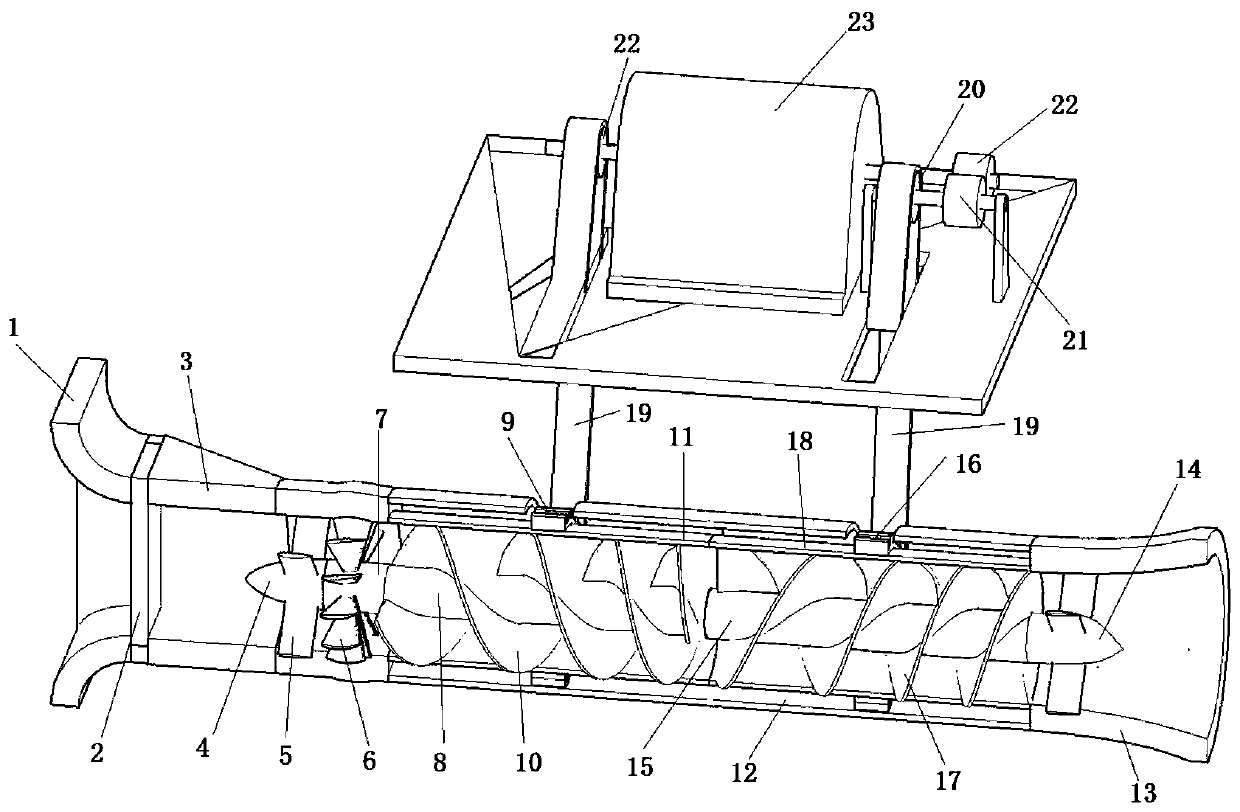

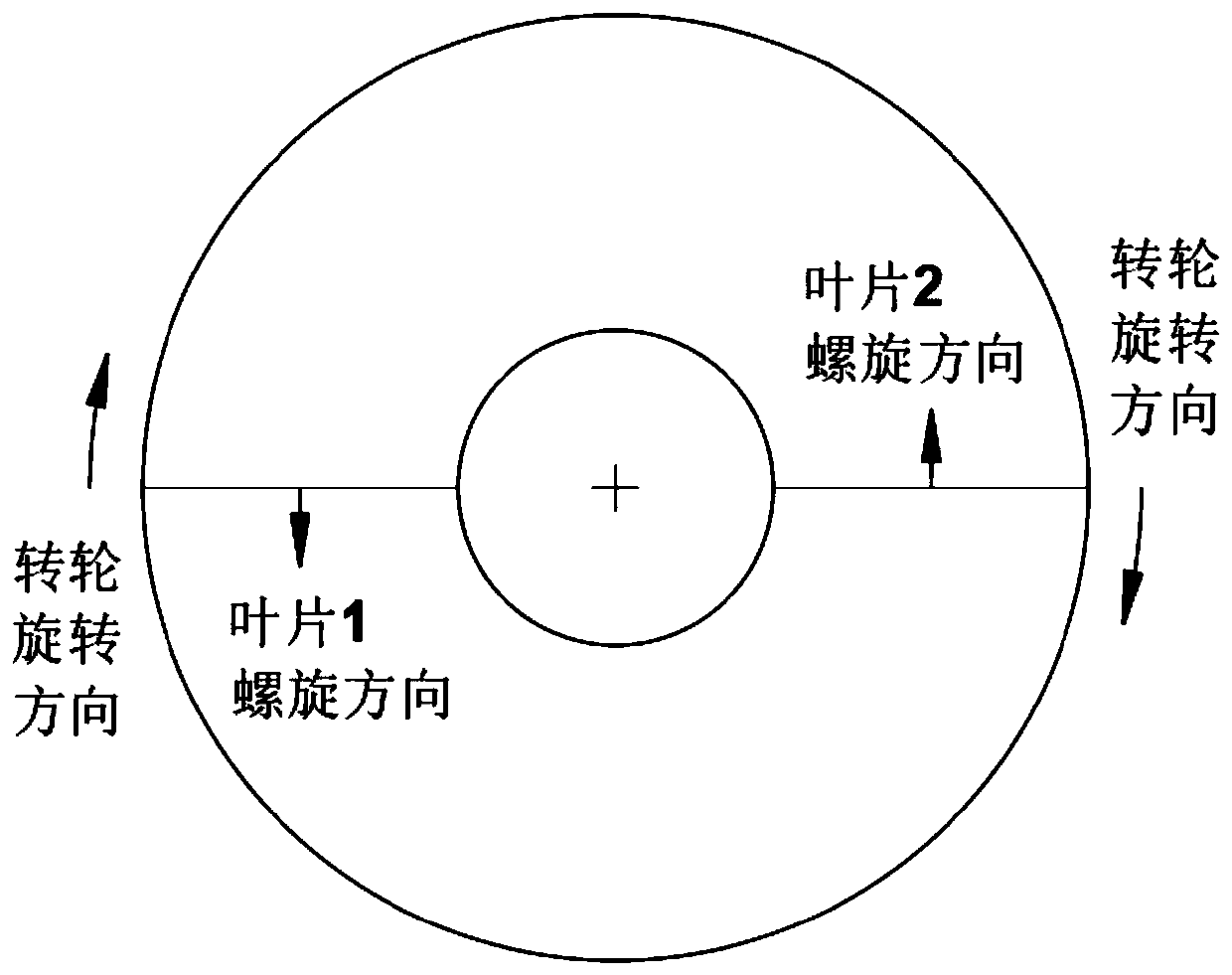

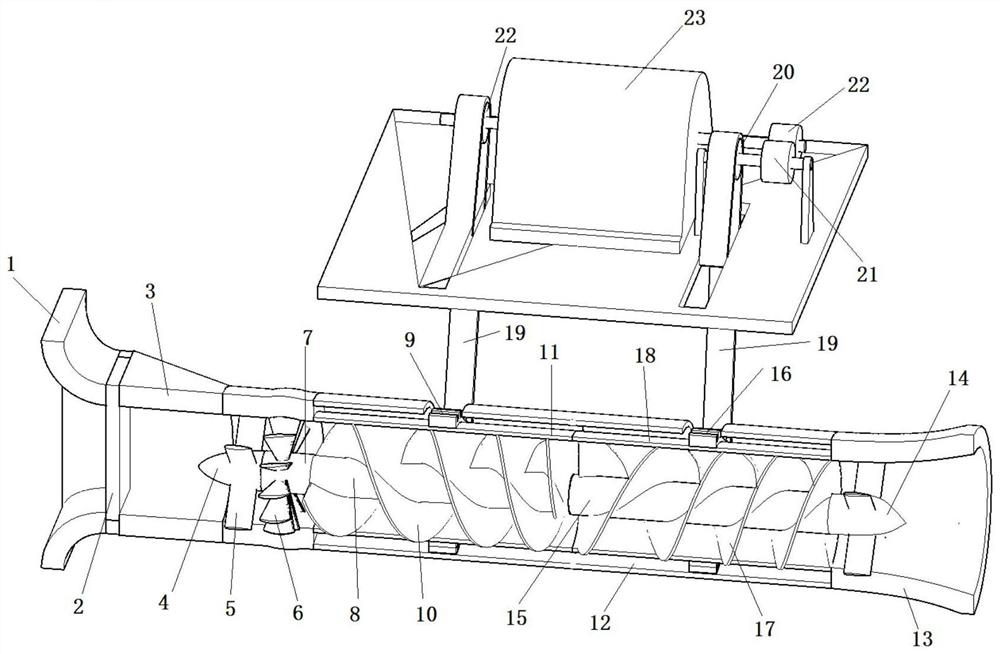

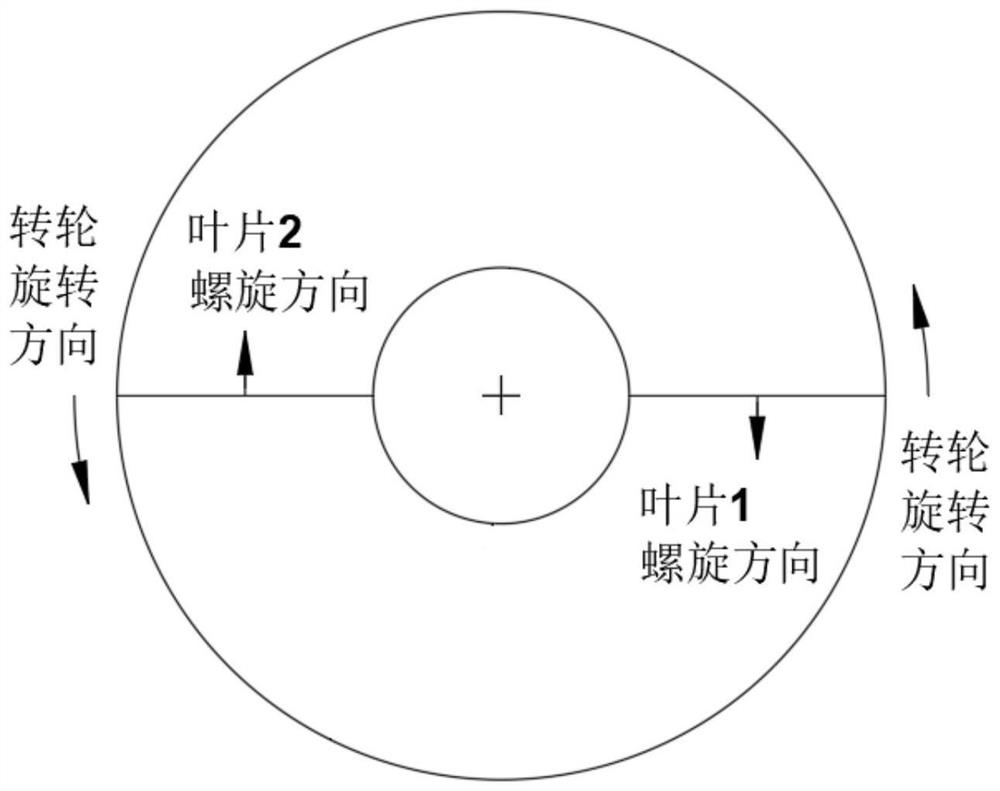

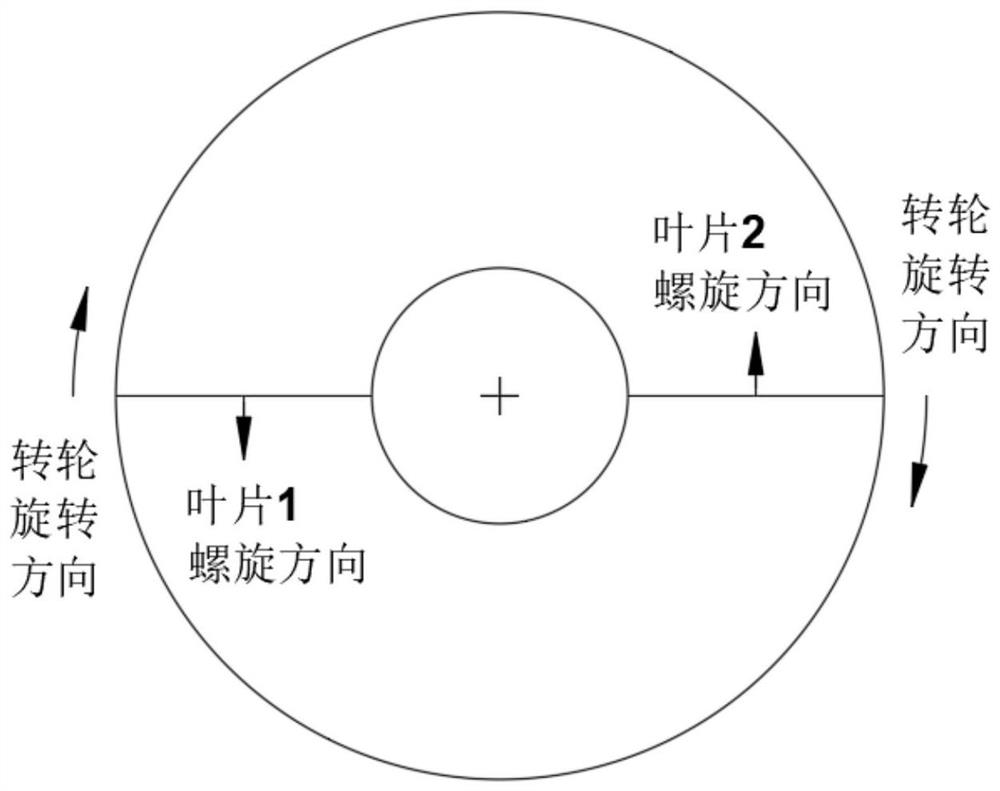

Spiral-blade opposite-rotation type double-runner water turbine

ActiveCN110397545ARelieve stress changesReduce the pressure gradientHydro energy generationReaction enginesCavitationWater turbine

The invention provides a spiral-blade opposite-rotation type double-runner water turbine. The water turbine comprises a diffusion section, a square-circle transition section connected with the diffusion section, a shell connected with the square-circle transition section, and a tail water section connected with the shell, and further comprises a front-section runner and a rear-section runner whichare arranged in the shell; and each of the front-section runner and the rear-section runner comprises an inner cylinder, a spiral blade with a double-helix structure arranged on the inner cylinder and an outer cylinder arranged outside the spiral blade, the inner cylinders, the spiral blades and the outer cylinders are in an integrated structures correspondingly and rotate around a fixed shaft arranged in the shell, and the rotating directions of the front-section runner and the rear-section runner are opposite. According to the water turbine, the two-section structure design is adopted, so that a long flow channel can reduce the pressure gradient in the flow channel; the front-section runner and the rear-section runner rotate reversely, so that a rotating flow state can be eliminated; and the inner cylinders, the spiral blades and the outer cylinders integrated structures prevent cavitation between the blades and the outer cylinders correspondingly, so that the probability of mechanical damage of fishes is reduced.

Owner:WUHAN UNIV

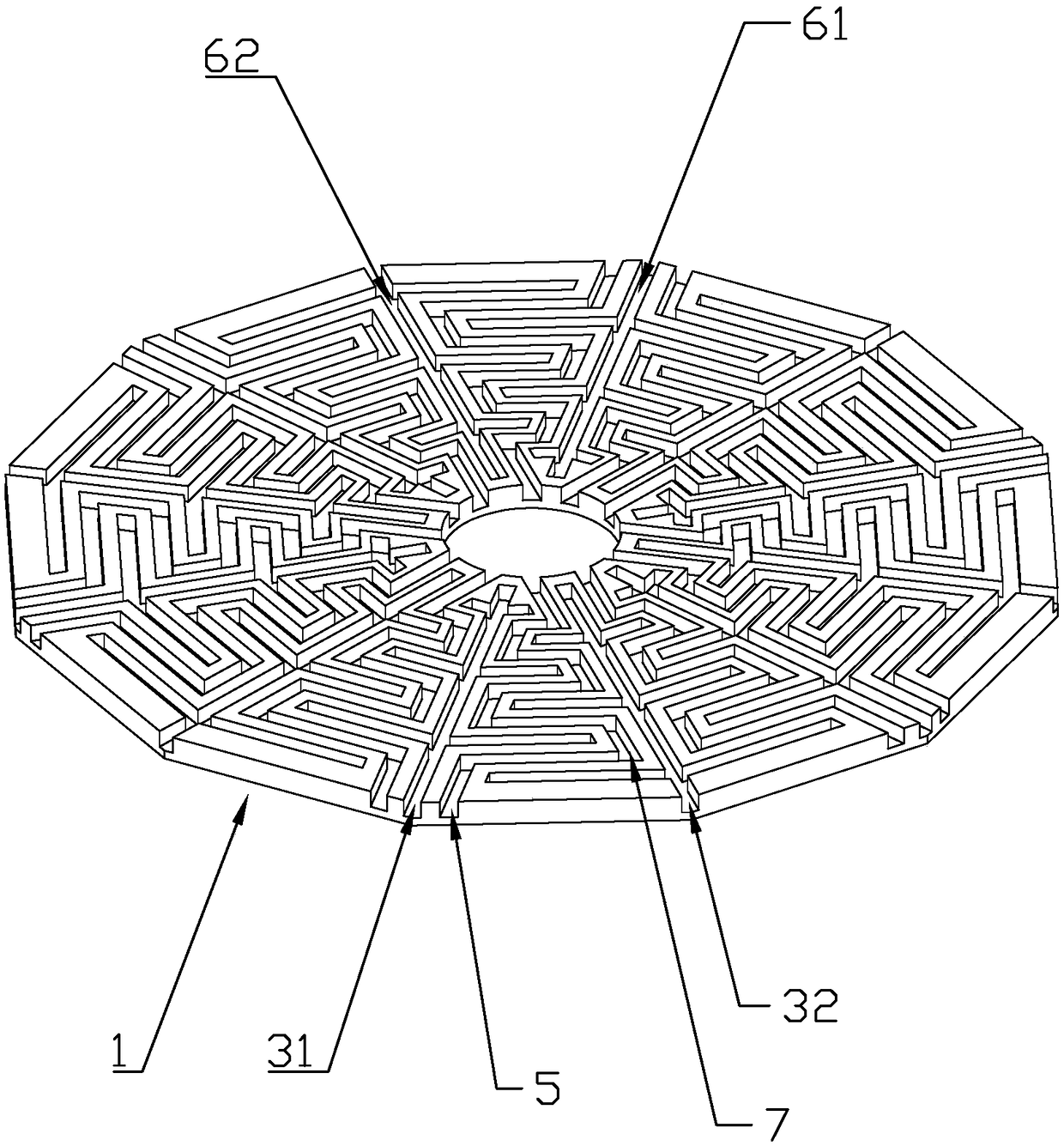

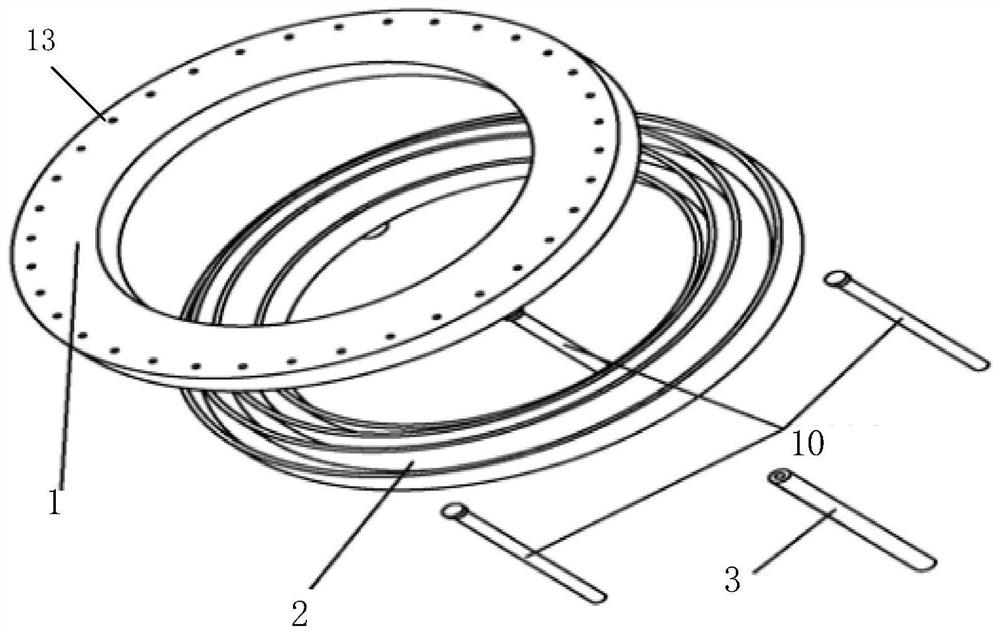

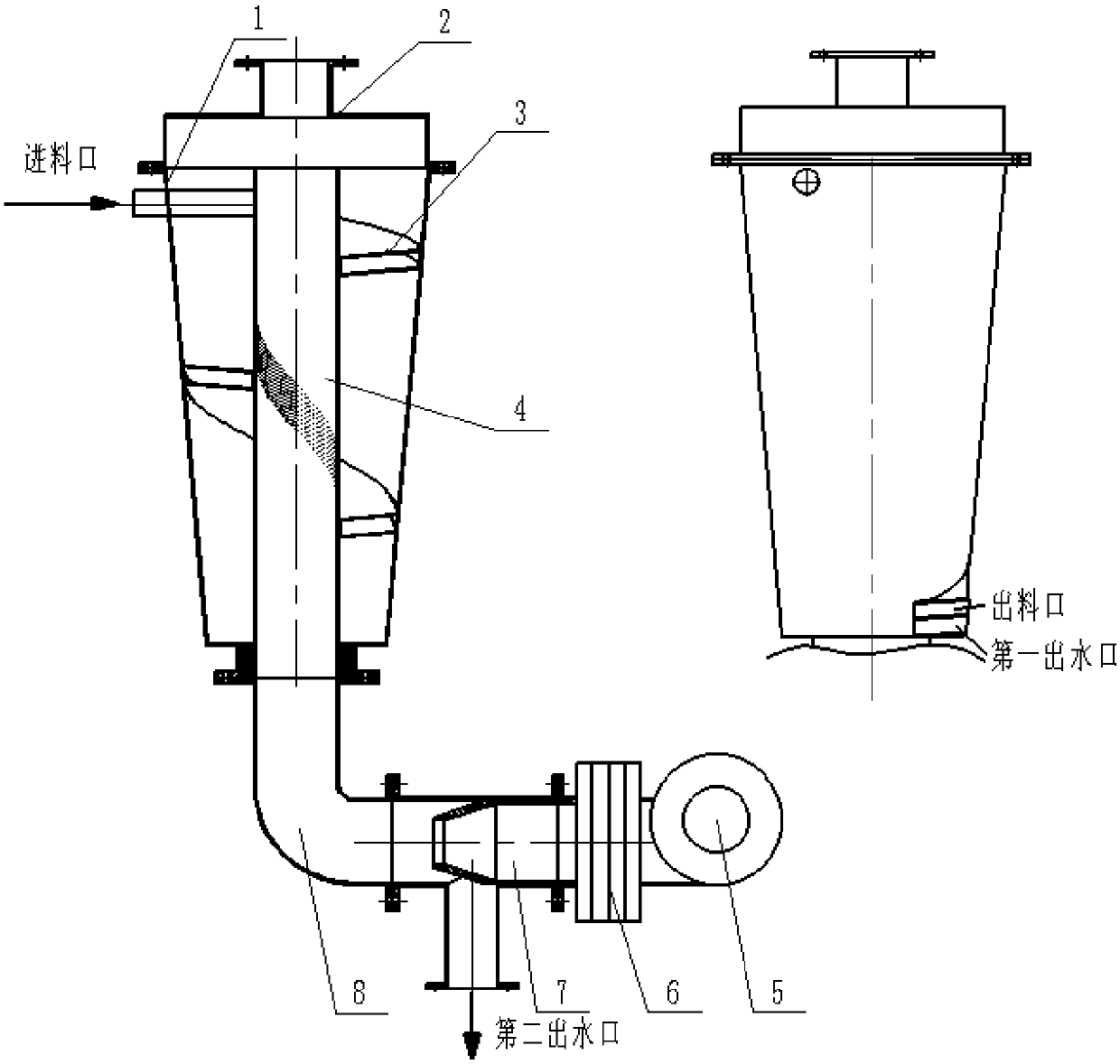

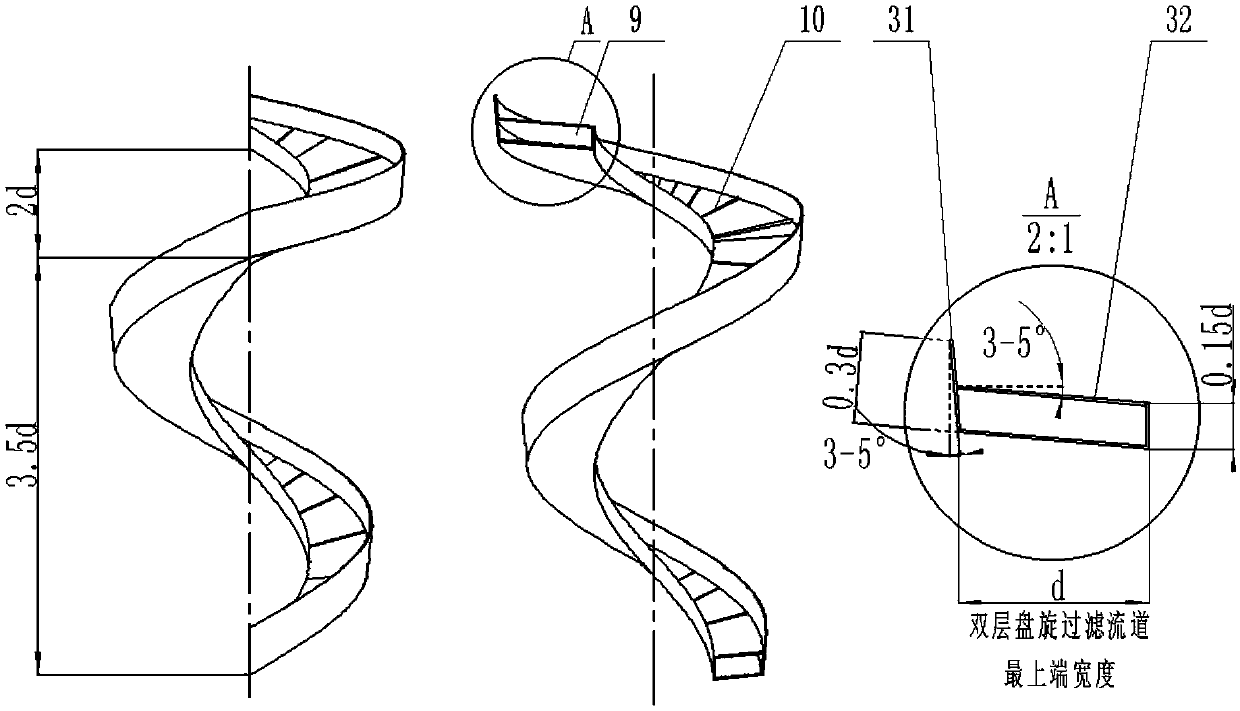

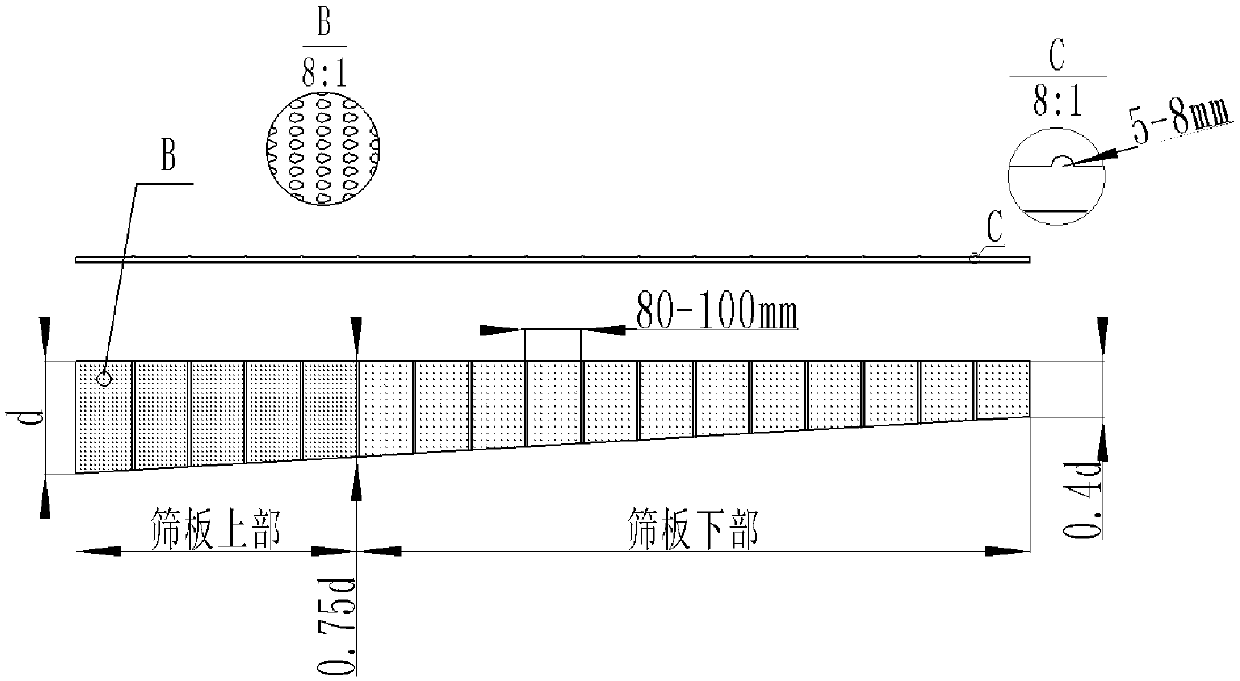

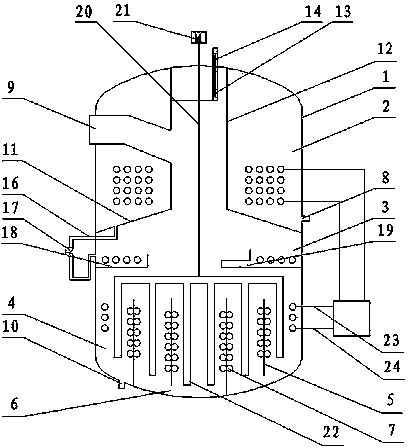

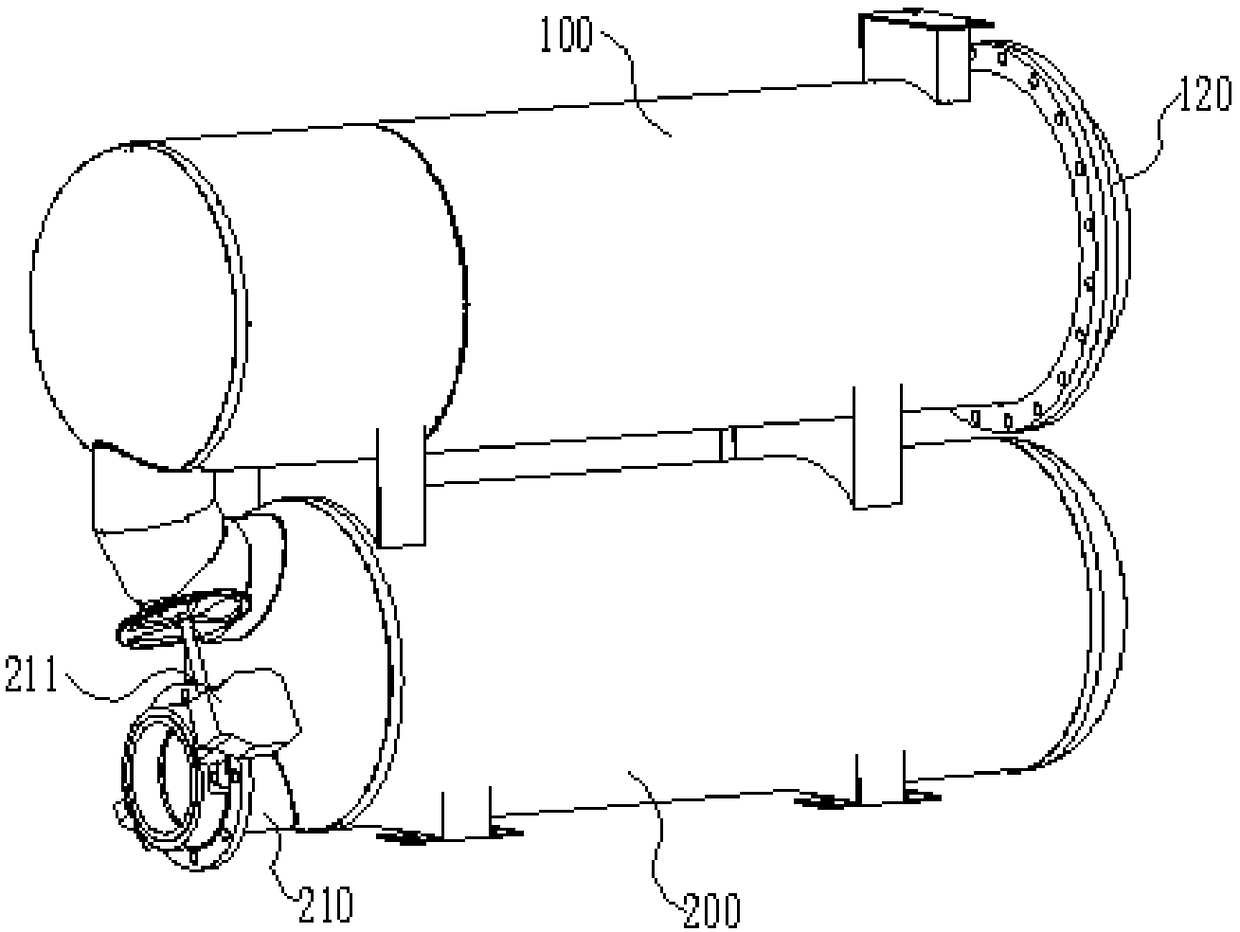

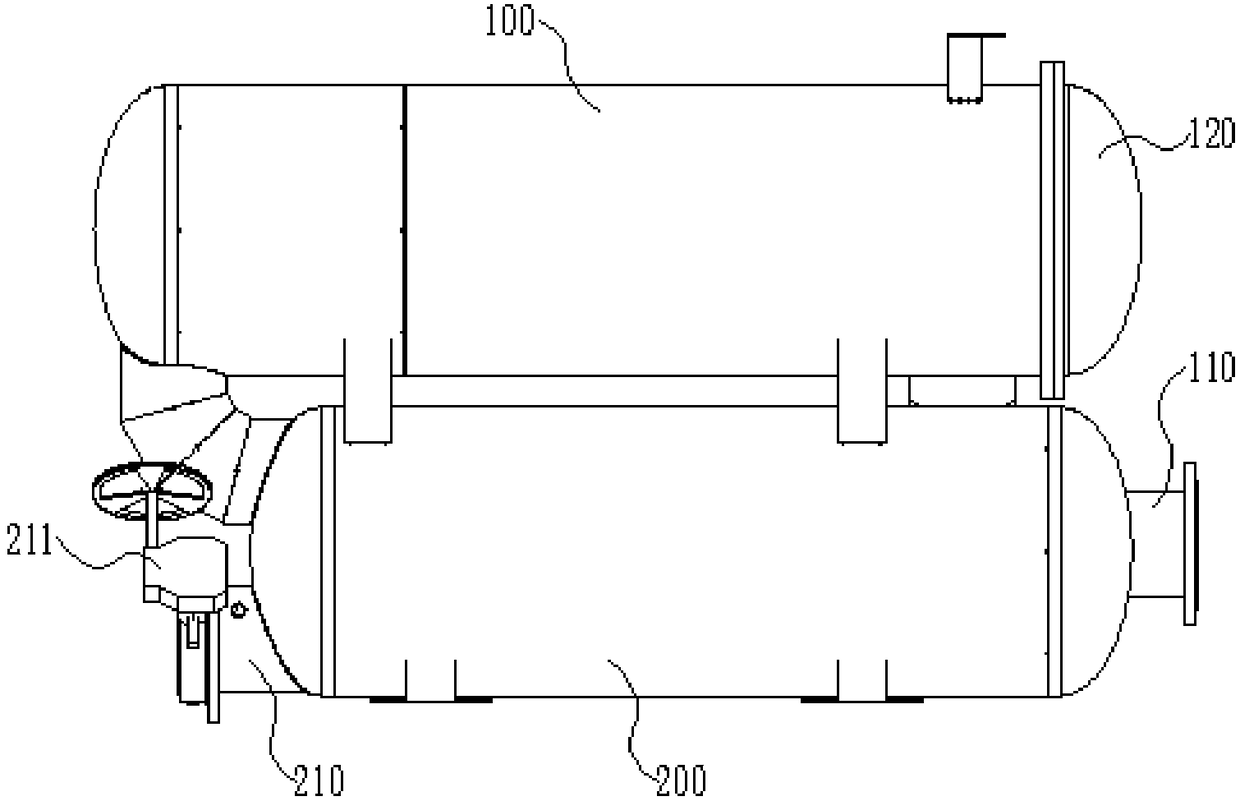

Hydrocycloneseparation dryer for solid-liquid separation of water-bearing granular materials

ActiveCN109539699AImprove dehydration effectImprove separation efficiencyDrying solid materials with heatDrying gas arrangementsProcess engineeringMoisture

The invention discloses a hydrocycloneseparation dryer for solid-liquid separation of water-bearing granular materials. The hydrocycloneseparation dryer comprises a hydrocyclone separation drying device (I) and an air supplying device (II); the hydrocyclonedrying device comprises an outer cavity (1), an upper end cover (2), a double-layer spiral filtering flow passage (3) and an air supplying pipe(4); the double-layer spiral filtering flow passage comprises a water tank (31) and a sieve plate (32); and the air supplying device comprises a fan (5), an air duct heater (6) and a venturi air supplying device (7). The hydrocyclonedrying device is connected with the air supplying device through a connecting elbow pipe (8). According to the hydrocycloneseparation dryer for solid-liquid separation of the water-bearing granular materials, the length of a separation flow passage per unit volume is increased, the double-layer spiral filtering flow passage is adopted, and wind drying is combinedwith the double-layer spiral filtering flow passage, so that the particle drying efficiency is improved. According to design, collision of particles in the drying process is reduced, the drying efficiency of the particles is improved and the volume of the hydrocycloneseparation dryer is effectively decreased, and especially for the difficult handling granular materials with the moisture content being greater than or equal to 95%, effective dehydration treatment can be achieved. The hydrocycloneseparation dryer for solid-liquid separation of the water-bearing granular materials is reasonable indesign, compact in structure, and easy to apply and popularize.

Owner:BEIJING UNIV OF CHEM TECH +1

A chain-staggered microchannel structure

ActiveCN104465562BSpeed up the flowLower coefficient of frictional resistanceSemiconductor/solid-state device detailsSolid-state devicesLeading edgeDie swell

Owner:XIDIAN UNIV

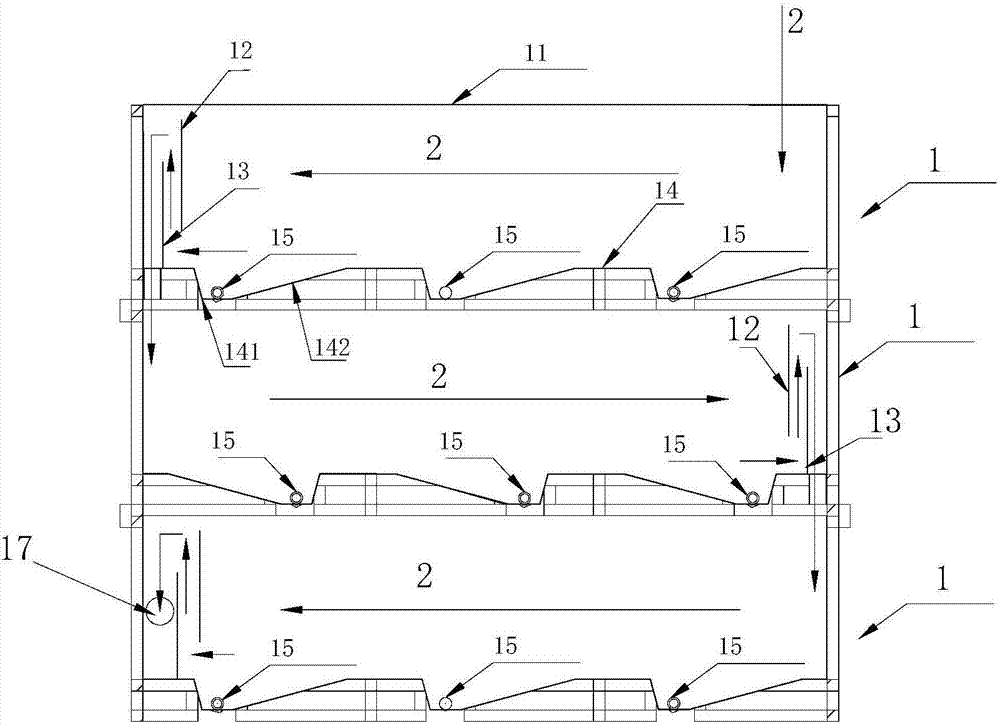

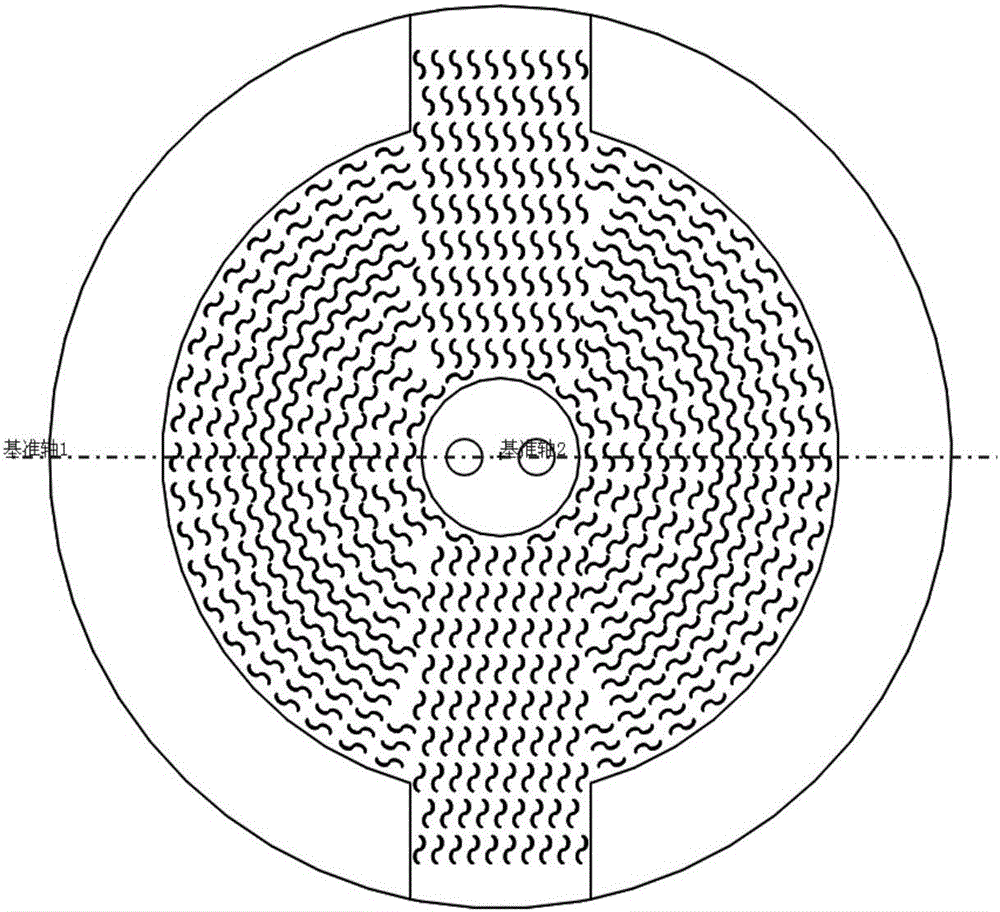

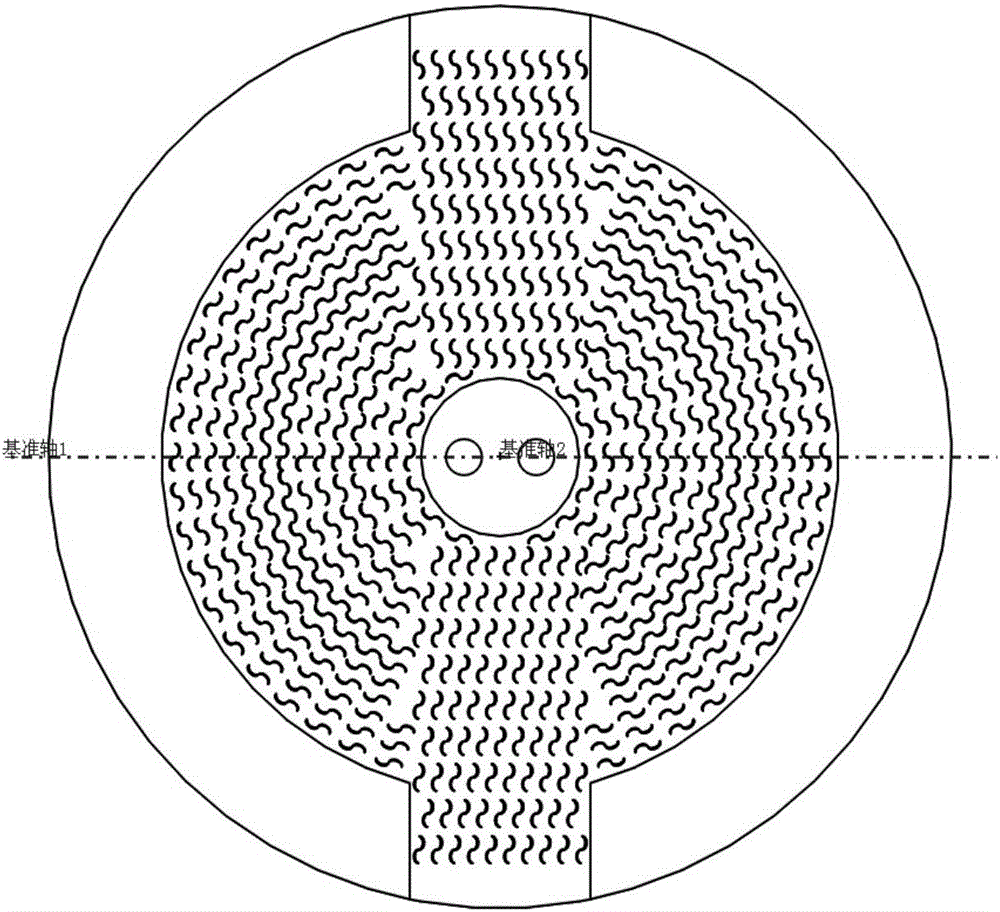

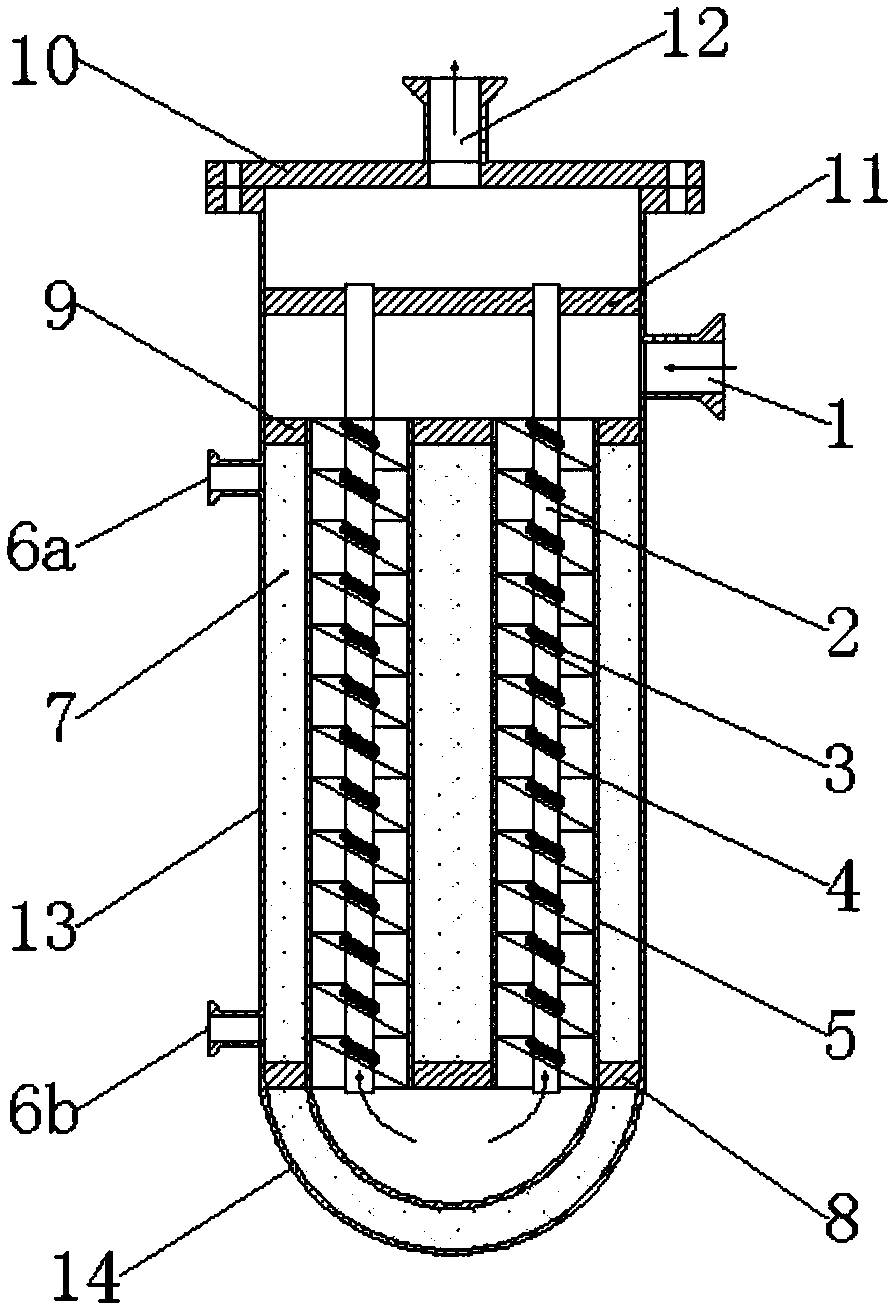

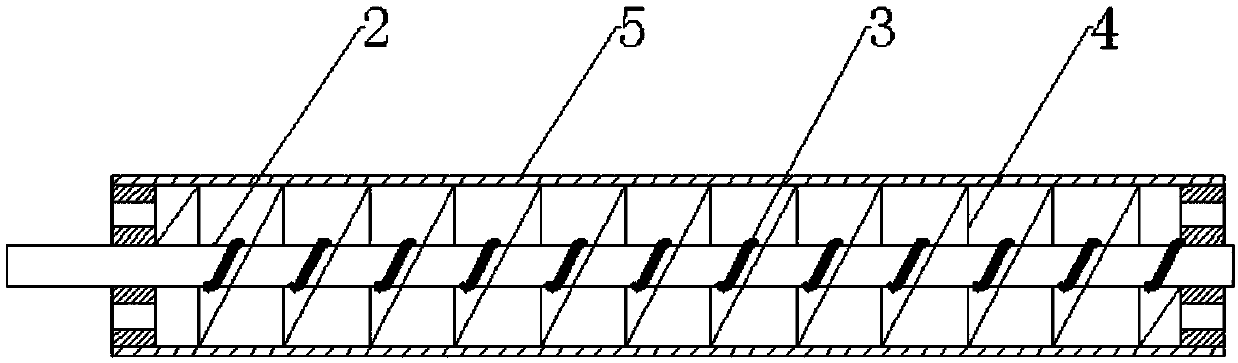

Pre-polycondensation reactor

ActiveCN102775584BIncrease the length of the runnerExtended flow timeChemical/physical/physico-chemical stationary reactorsEngineeringFlow time

The invention relates to a pre-polycondensation reactor which comprises a shell, wherein an upper-layer partition and a lower-layer partition are arranged in the shell to divide the shell into an upper chamber, a middle chamber and a lower chamber; the lower chamber is divided into a plurality of annular regions by a plurality of concentrically arranged annular partitions; the central line of the concentrically arranged annular partitions coincides with the central line of the shell; each annular partition is provided with a channel hole communicated with the annular regions on the two sides; and a heating coil is arranged in each annular region. Due to the adoption of a structure of series connection of multiple regions, the polymerization reaction area is elongated, thereby effectively prolonging the flow channel length of the polymerization reaction area; and under the condition of the same flow rate, the flow time of the material in the polymerization reaction area is prolonged, thereby effectively prolonging the total time of polymerization reaction and obviously enhancing the polymerization degree of the end product on the premise of not increasing the production time and cost or the diameter of the pre-polycondensation reactor.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

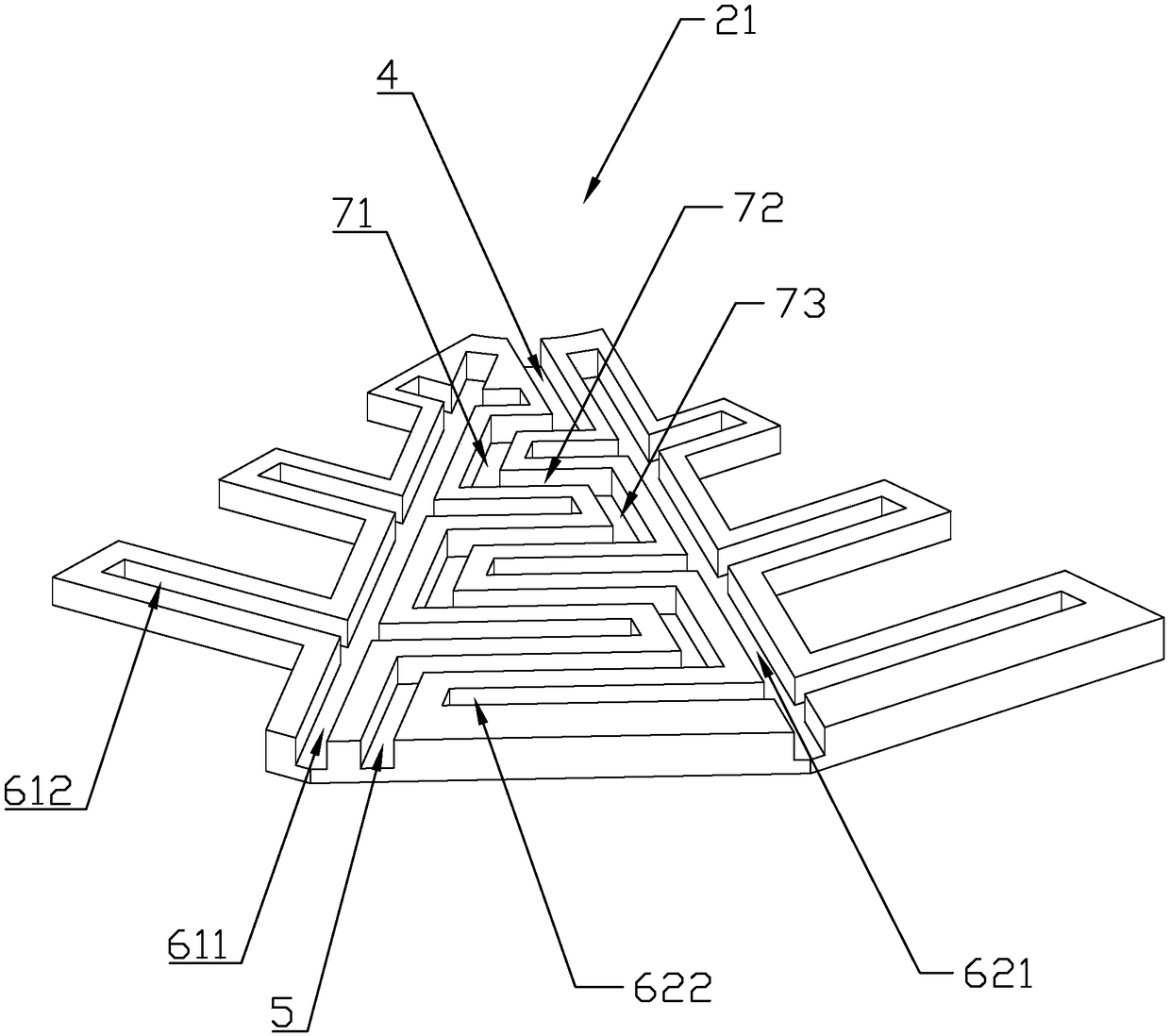

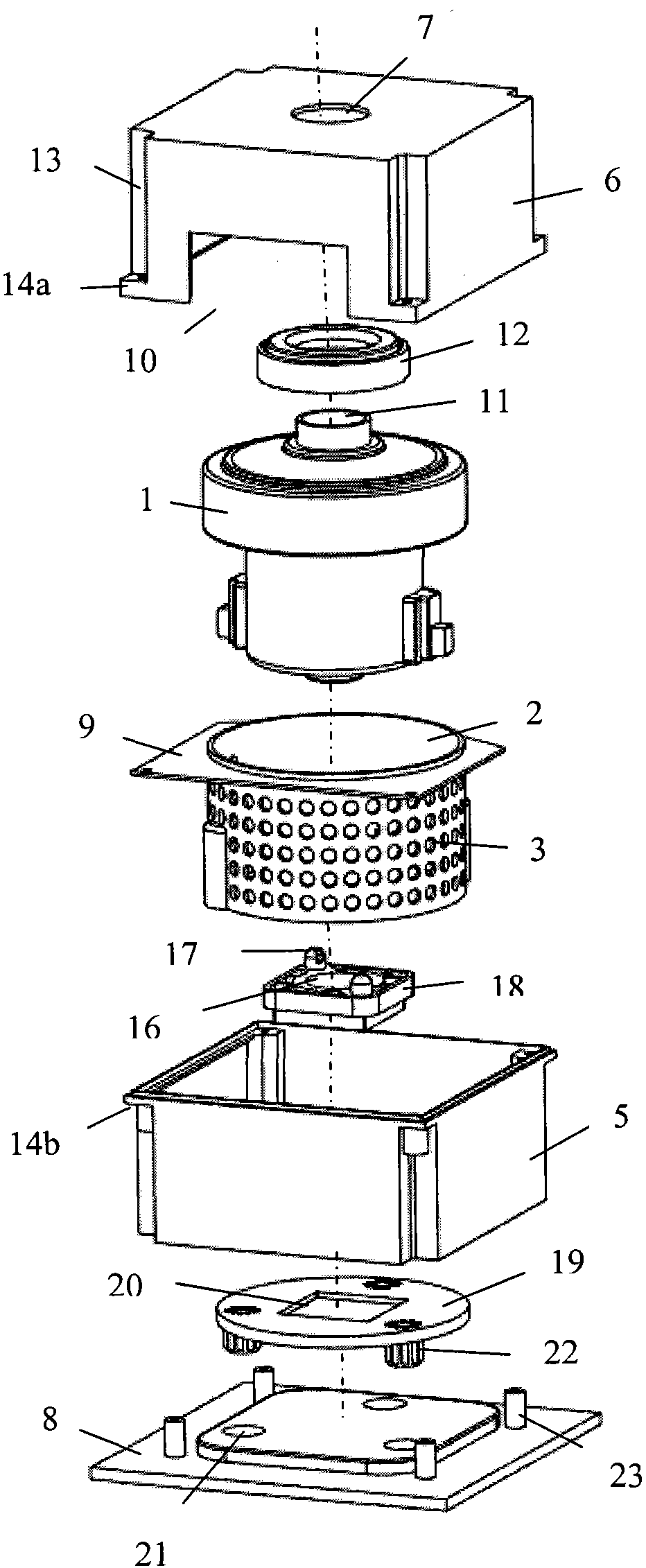

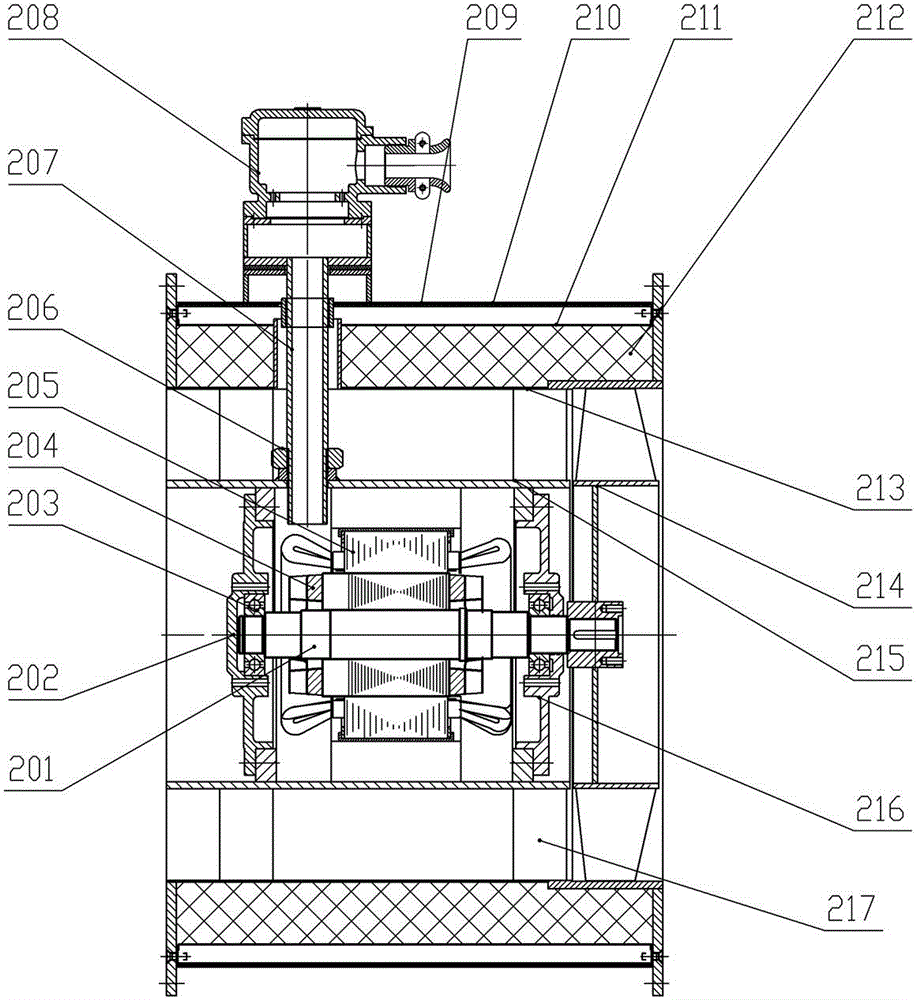

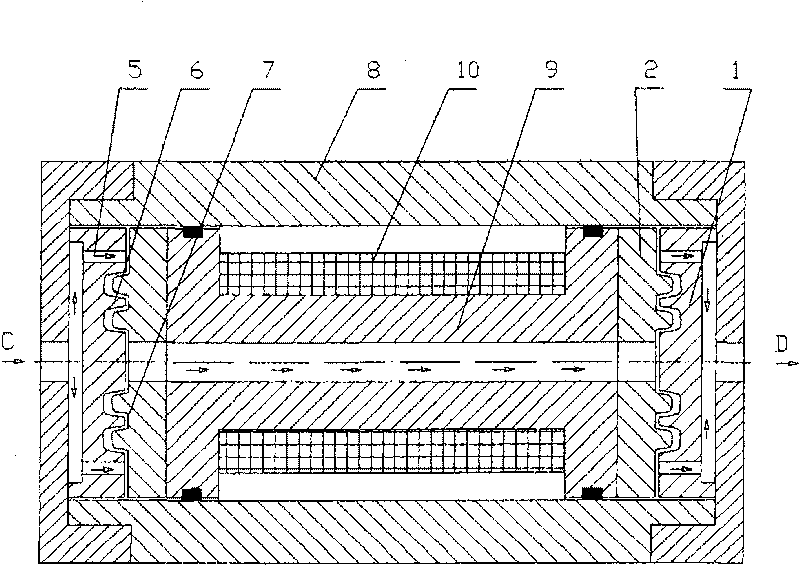

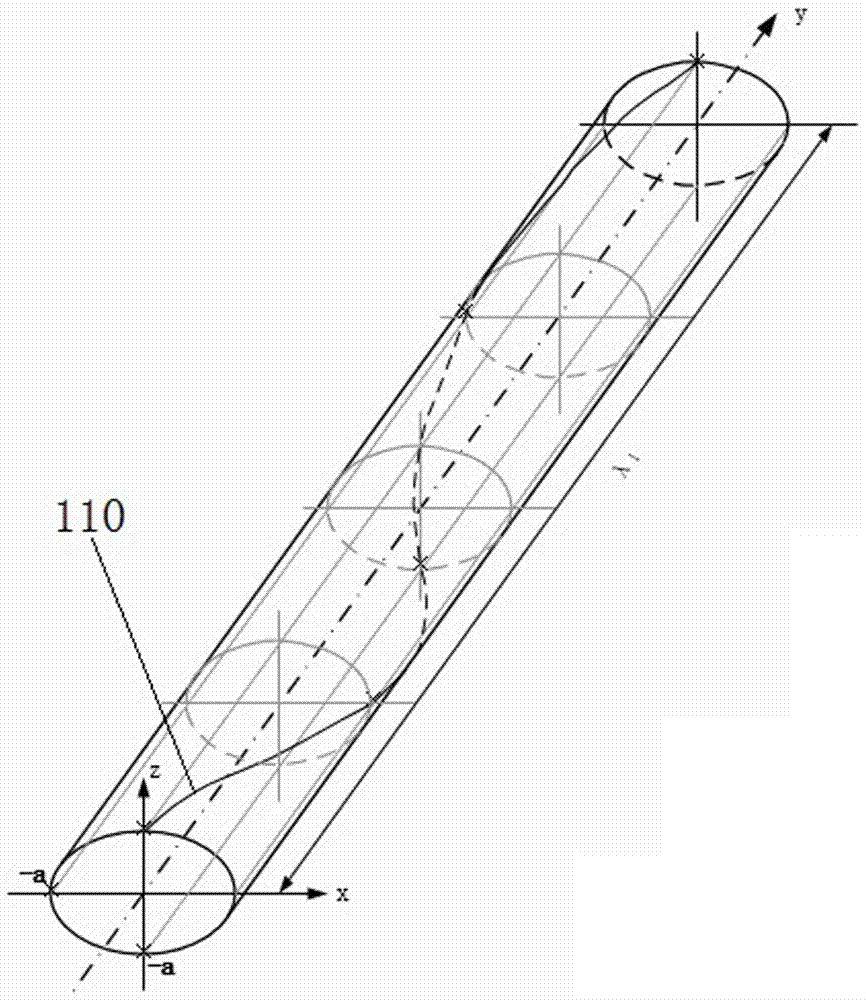

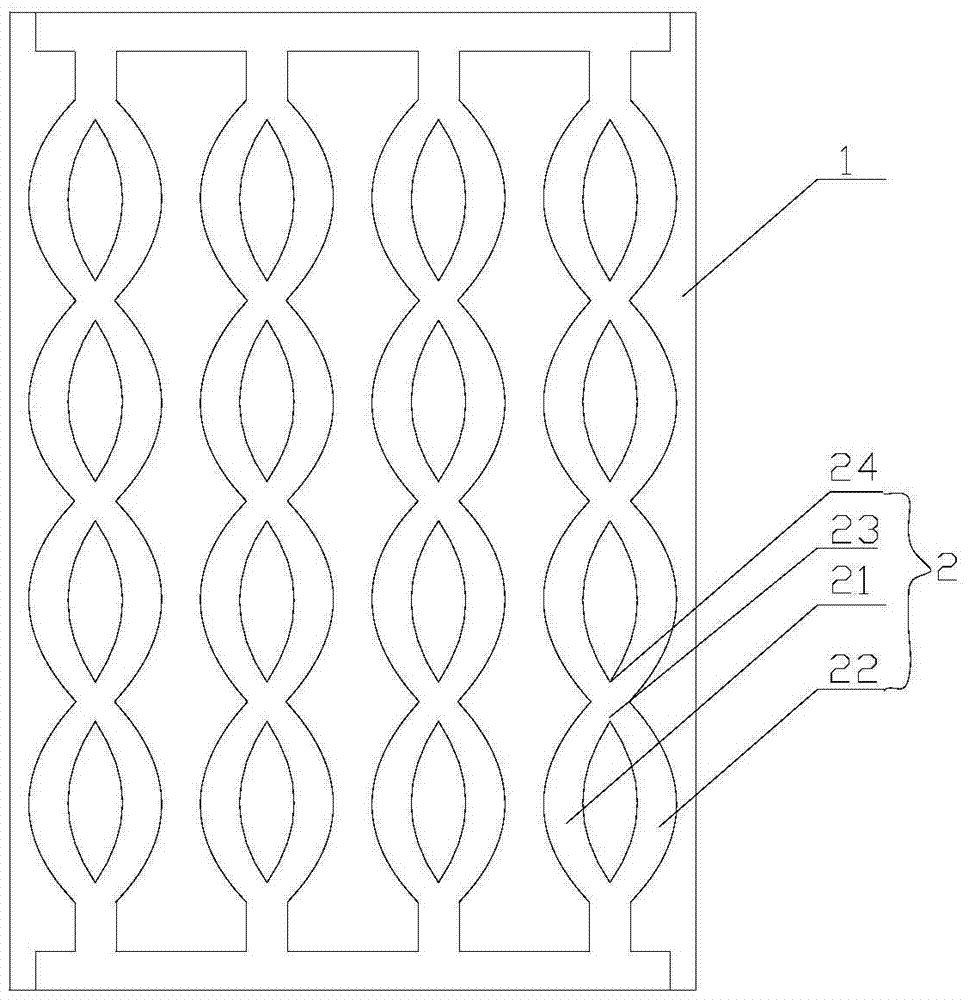

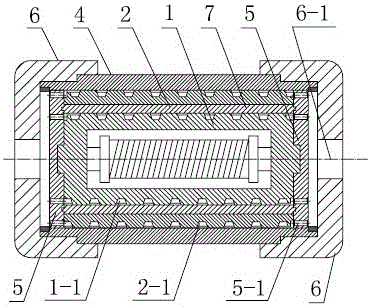

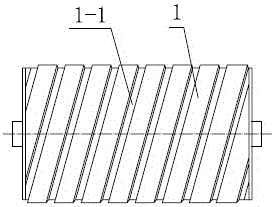

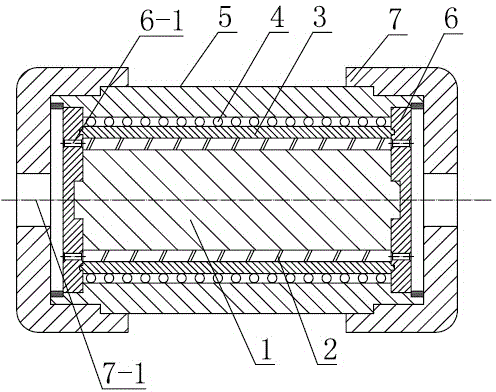

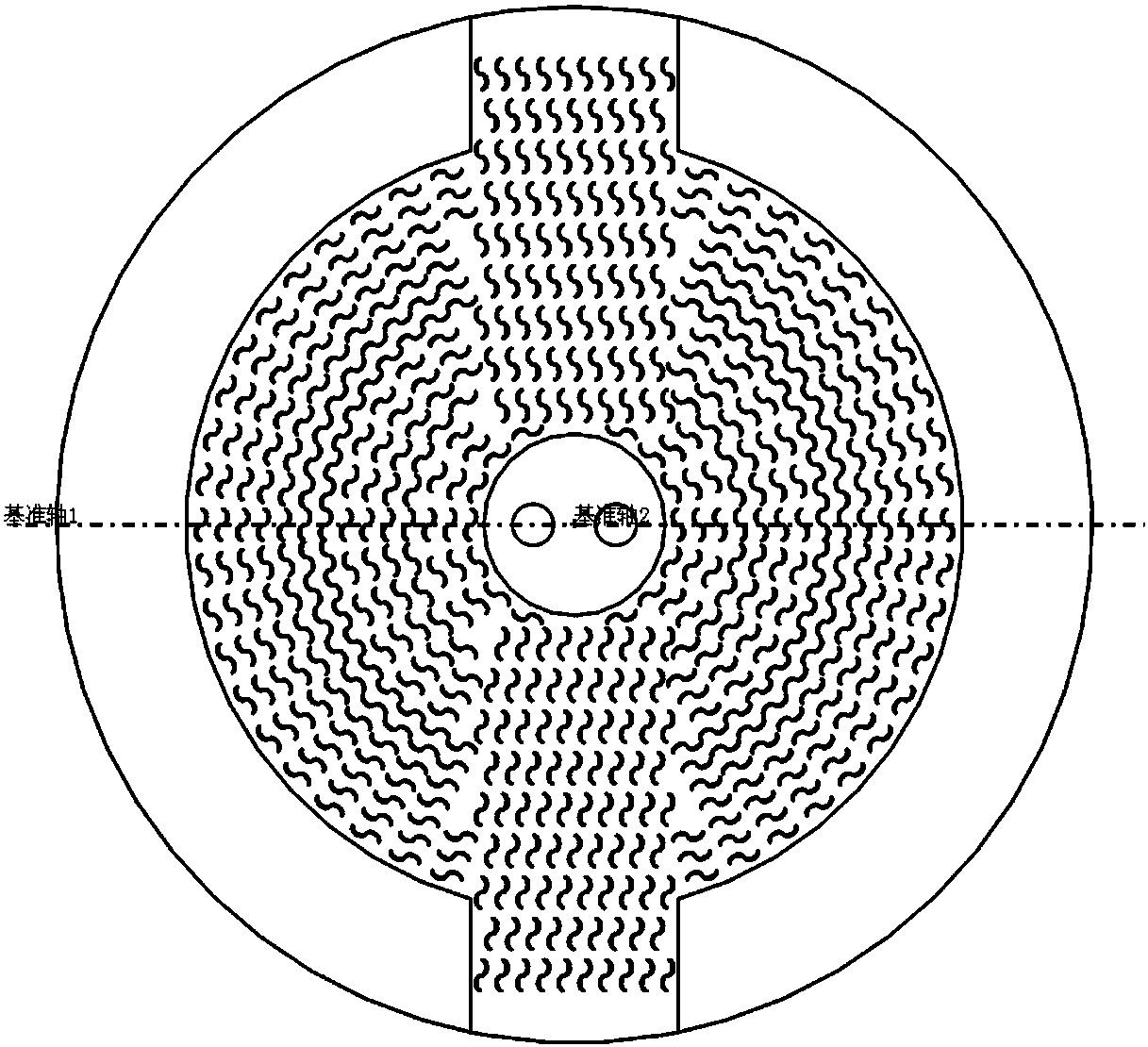

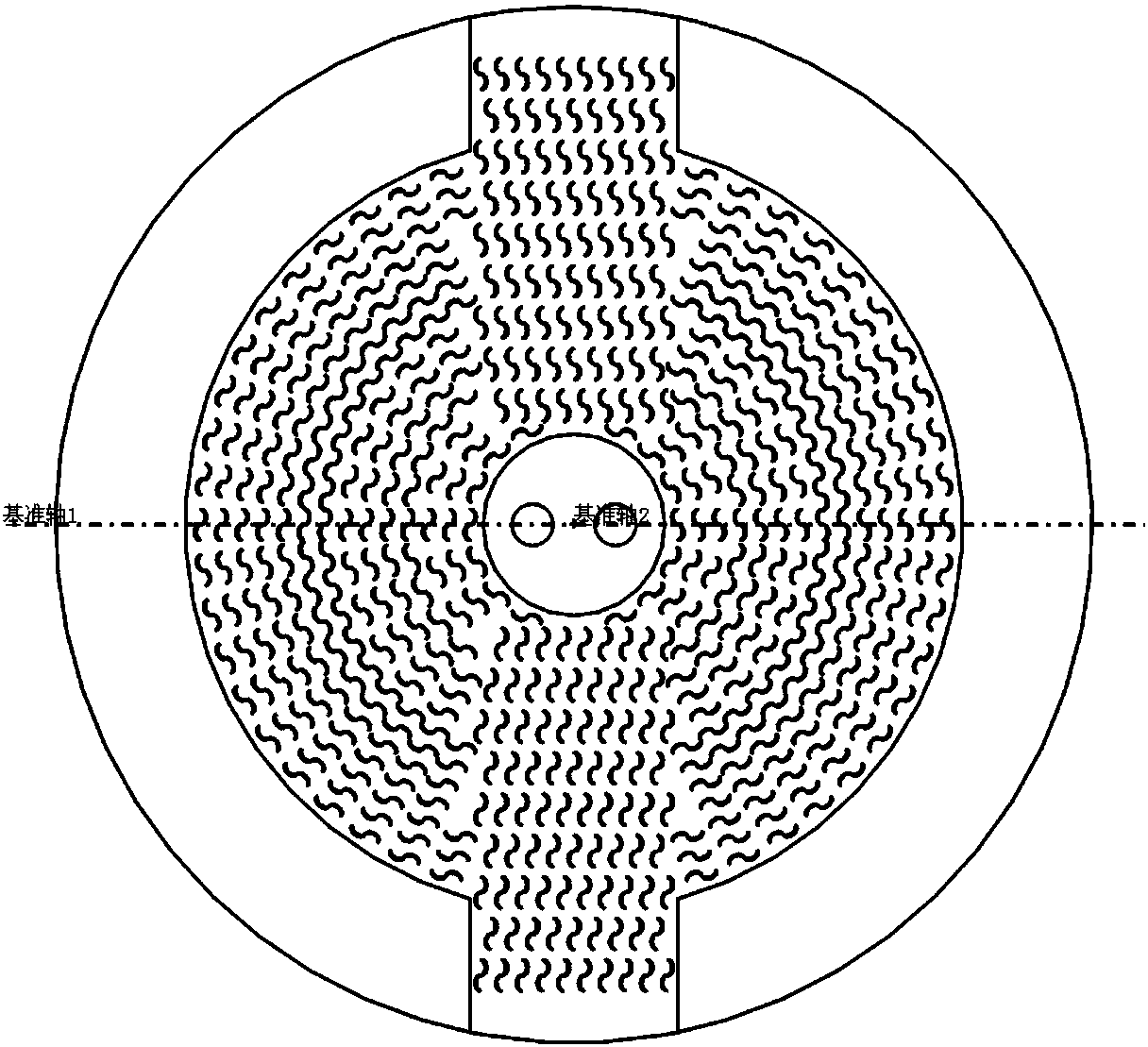

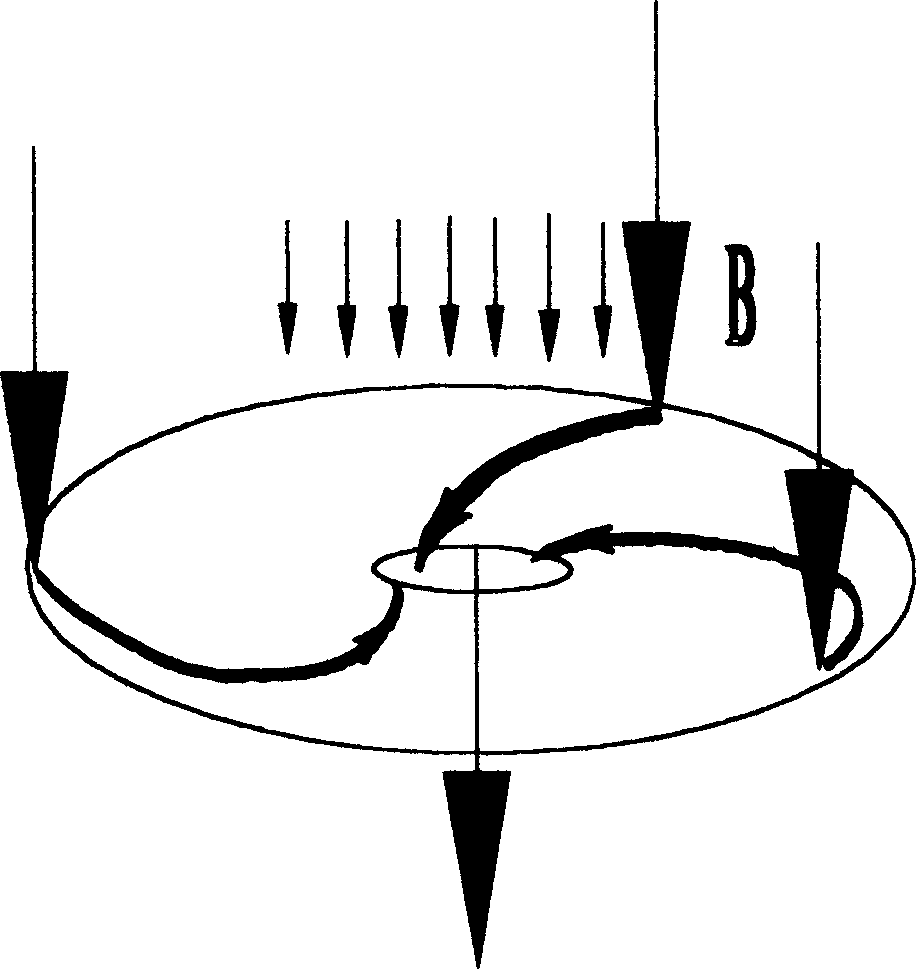

A magneto-rheological valve structure with three-dimensional helical flow channel

InactiveCN103775406BIncrease the length of the runnerIncrease the differential pressureServomotor componentsForce linesDifferential pressure

The invention discloses a magneto-rheological valve structure with three-dimensional spiral liquid flow channels. The aims of lengthening the lengths of the magneto-rheological flow channels and obtaining the large differential pressure are achieved. A valve element part in the structure comprises an inner flow guiding cylinder and an outer flow guiding cylinder, a magnet exciting coil is arranged in the inner flow guiding cylinder, the outer flow guiding cylinder and a valve body are of circular ring shapes, the inner flow guiding cylinder, the outer flow guiding cylinder and the valve body are sequentially installed in a sleeved mode, an inner three-dimensional spiral liquid flowing groove and an outer three-dimensional spiral liquid flowing groove are formed in the outer circle of the inner flow guiding cylinder and the outer circle of the outer flow guiding cylinder, the spiral flow channels are formed by the inner three-dimensional spiral liquid flowing groove and the inner wall of the outer flow guiding cylinder and formed by the outer three-dimensional spiral liquid flowing groove and the inner wall of the valve body, oil inlet-outlet discs are arranged on the end faces of the inner flow guiding cylinder and the end faces of the outer flow guiding cylinder, two sets of oil holes are formed in each oil inlet-outlet disc, the oil holes are communicated with the inner three-dimensional spiral liquid flowing groove and the outer three-dimensional spiral liquid flowing groove respectively, the valve body is arranged in valve body end covers, and oil holes in the valve body end covers are communicated with the oil holes in the oil inlet-outlet discs in the valve body. The magneto-rheological valve structure has the advantages that the length of an electromagnetic rheological path is lengthened, the use rate of magnetic force lines is improved, energy is saved, and the size of a magneto-rheological valve is reduced.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Heat exchanger core for heat exchange of three or more fluids

ActiveCN106440892ARealize simultaneous heat exchangeImprove heat transfer efficiencyLaminated elementsStationary plate conduit assembliesEtchingEngineering

The invention provides a heat exchanger core for heat exchange of three or more fluids, and belongs to the technical field of heat exchange design. The heat exchanger core comprises n heat exchange plate groups and is formed by alternately stacking the n heat exchange plate groups which bear n heat exchange fluids; each heat exchange plate comprises a via hole heat exchange plate and a through hole heat exchange plate; each via hole heat exchange plate comprises a via hole matrix, two fluid via holes and a heat exchange flow channel machined on the via hole matrix through chemical etching; each through hole heat exchange plate comprises a cold plate and a hot plate, wherein the cold plate comprises a cold plate matrix, a fluid through hole and a heat exchange flowing channel machined on the cold plate matrix through chemical etching, and the hot plate comprises a hot plate matrix, a fluid through hole and a heat exchange flowing channel machined on the hot plate matrix through chemical etching; each heat exchange plate group comprises one or more cold plate or hot plates. The heat exchanger core for heat exchange of the three or more fluids has the advantages of being high in cooling efficiency and the like.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

A casing type gas electric heating device

ActiveCN106369819BIncrease the heating areaIncrease the length of the runnerAir heatersEngineeringElectric heating

The invention discloses a casing pipe type gas electric heating device. The device comprises a gas inlet, a gas outlet, a shell, an inner pipe, an outer pipe, an electric heating wire, fins, a heat insulation layer and other components; the casing pipe type structural design is adopted in the gas electric heating device, the spiral fins are arranged outside the inner pipe, the electric heating wire is wound on the outer surface of the inner pipe along a gap between two adjacent spiral fins, the outer pipe is arranged on the outer sides of the fins, a whole casing pipe is fixed in the shell, and the heat insulation layer is arranged between the outer pipe and the shell. A spiral winding gas flow way is formed between the spiral fins and the outer pipe, the gas flow way is prolonged, and the device is high in heating speed and uniform in gas heating; heated gas flows through the winding type flow way on the outer side of the inner pipe, is heated to a certain temperature and then is reheated through the inner side of the inner pipe, the wall temperature of the outer pipe is relatively low, meanwhile, the heat insulation layer is arranged between the shell and the outer pipe of the electric heating device, heat dissipation losses are reduced, and the heat efficiency of the device is improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

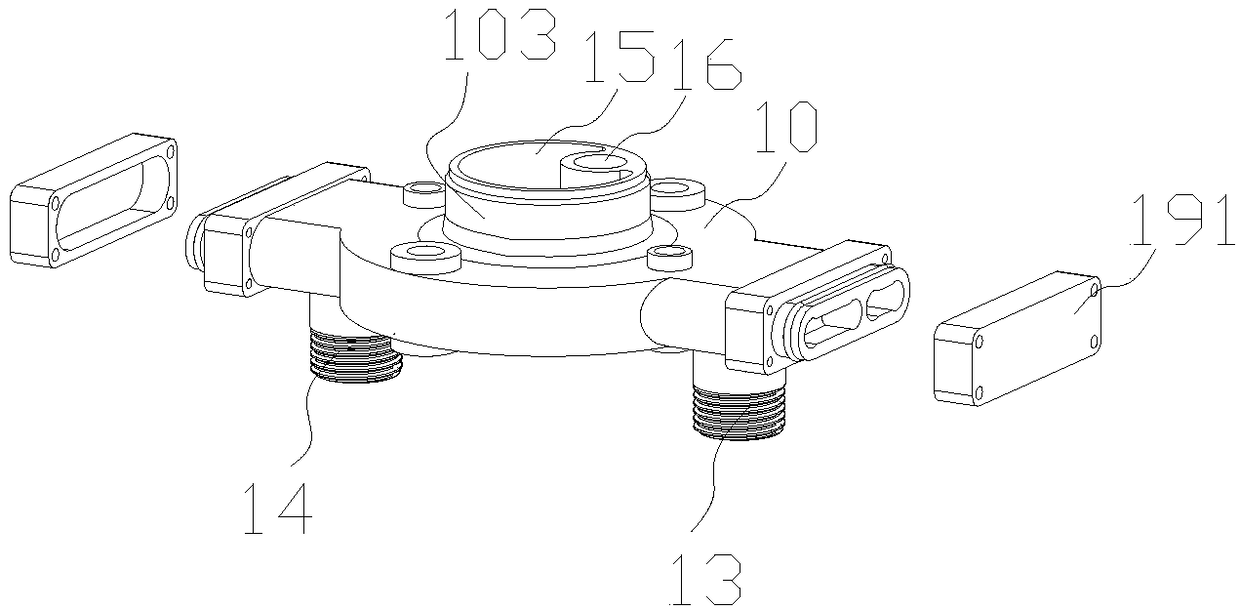

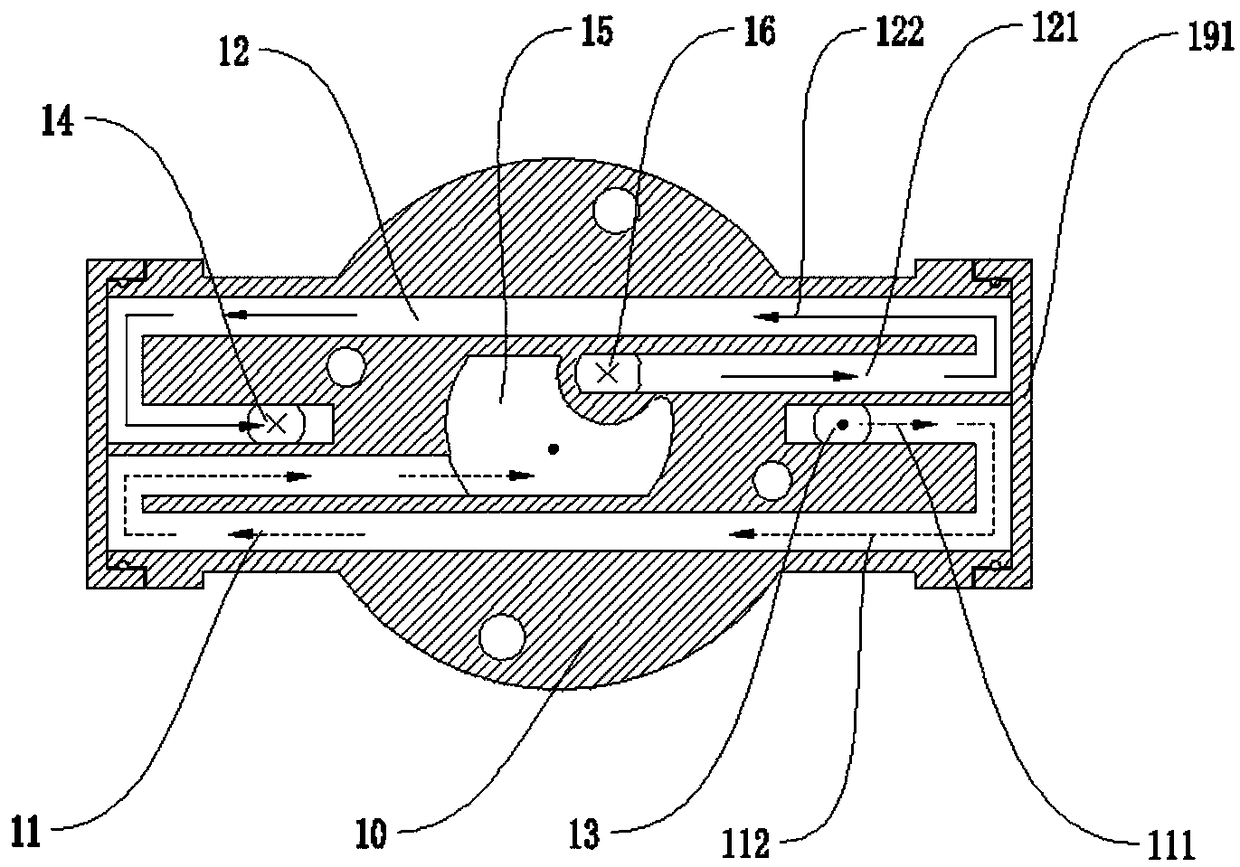

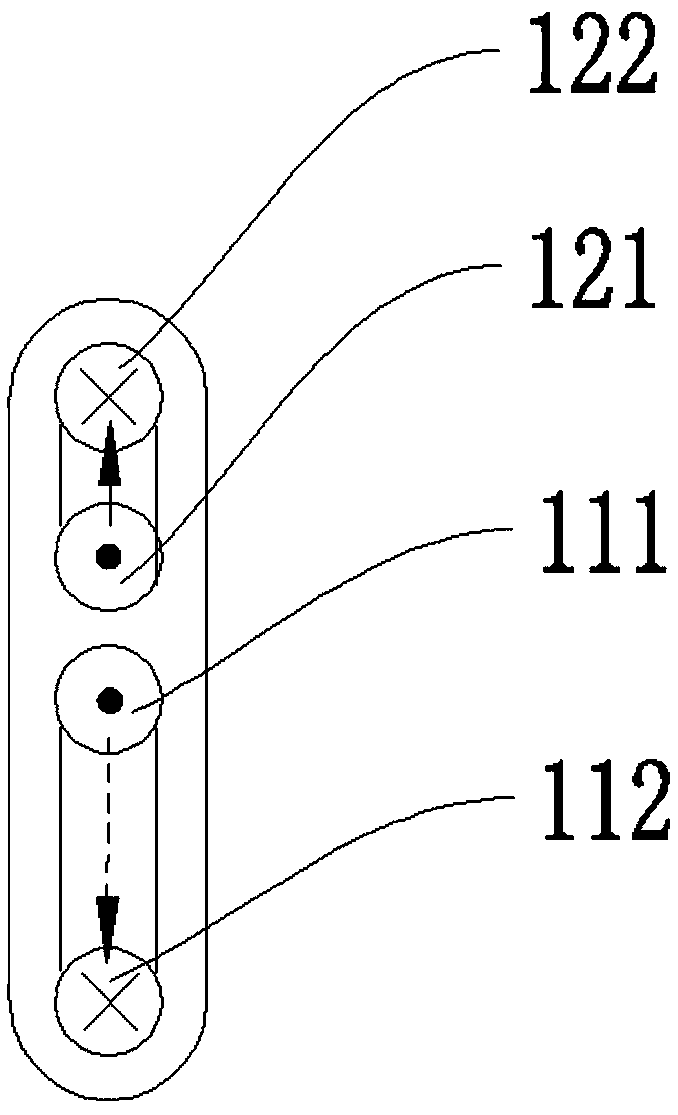

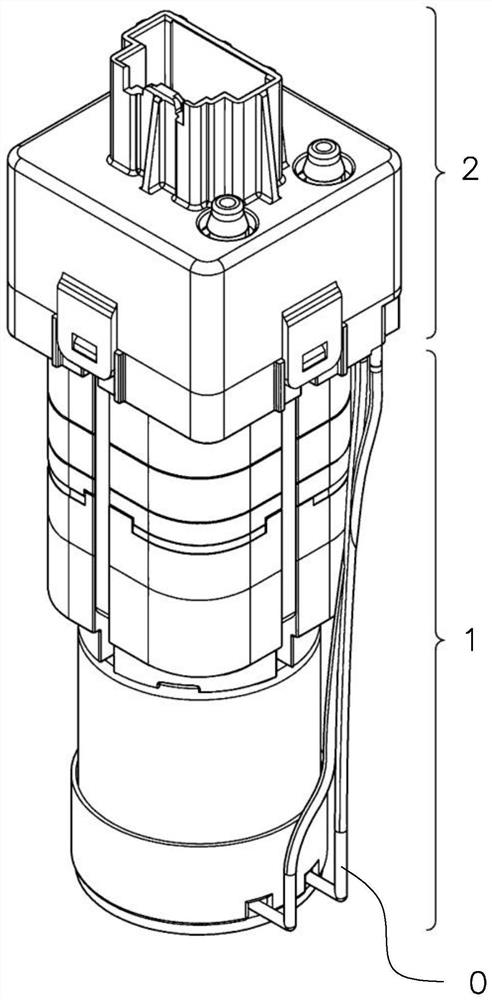

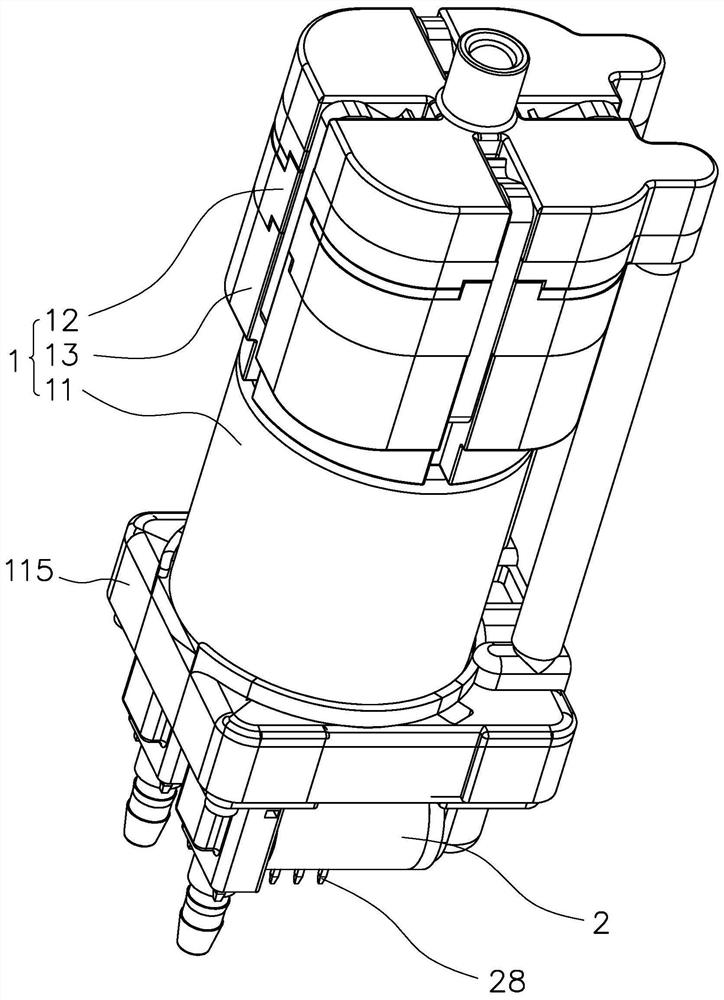

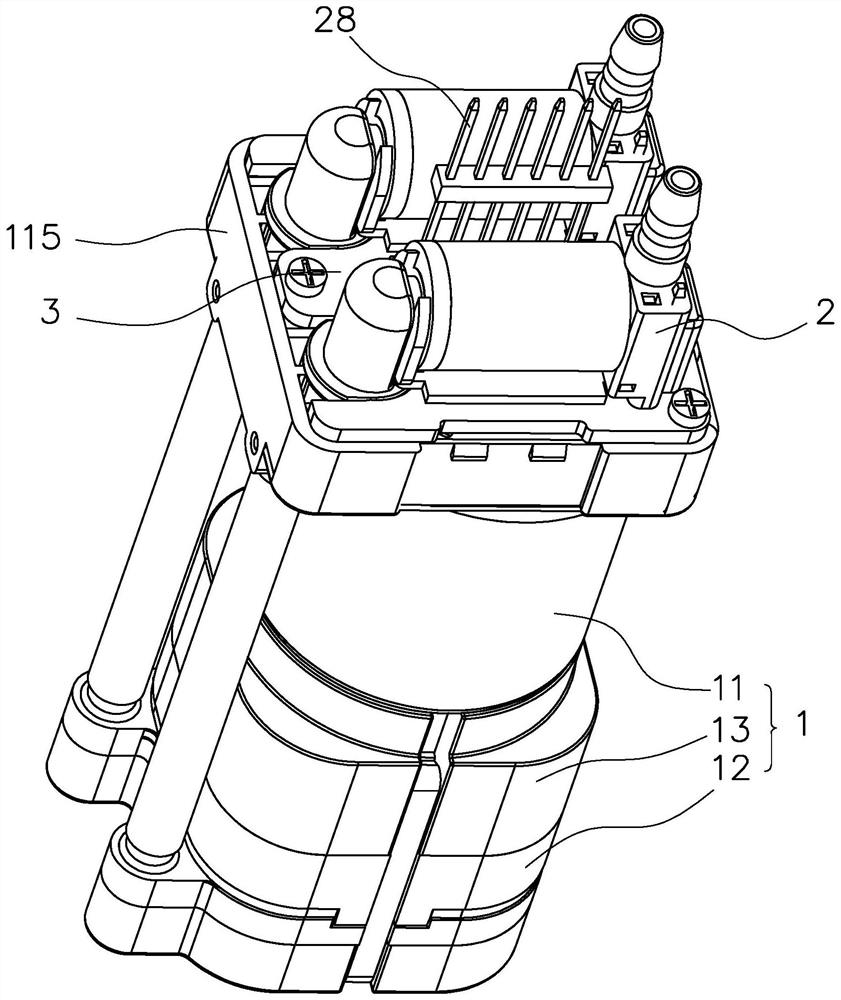

Pump and valve integrated module

PendingCN112746947AReduce usageSimplify electrical control connectionsAssociation with control/drive circuitsPositive displacement pump componentsEngineeringElectric control

The invention relates to a pump and valve integrated module, and relates to the technical field of fluid conveying. The pump and valve integrated module comprises a fluid supply assembly and a valve assembly, wherein the fluid supply assembly comprises a motor structure and a pump head arranged on the motor structure, the motor structure is provided with a power connection pin, the valve assembly is provided with a power connection terminal, the motor structure is provided with a rotating shaft end and a pin end, the pump head is installed at the rotating shaft end, the valve assembly is installed at the pin end, an electric control piece is arranged at the pin end, and the power connection pin and the power connection terminal are both connected to the electric control piece. The electric connection pin of the fluid supply assembly and the electric connection terminal of the valve assembly are both located at the pin end of the motor structure and are both directly connected to the electric control part, so that the use of leads is reduced, and the electric control connection between the fluid supply assembly and the valve assembly is simplified.

Owner:XIAMEN KOGE MICRO TECH

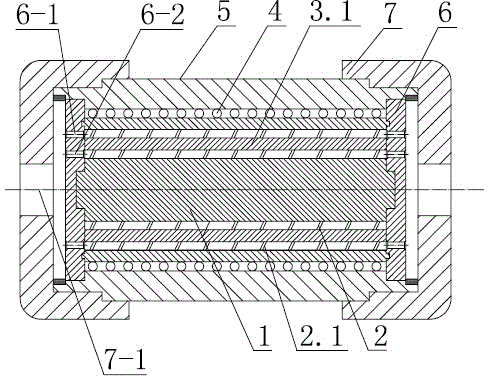

A three-dimensional swirling magnetic gap magnetorheological valve structure

InactiveCN103775407BIncrease the length of the runnerIncrease the differential pressureServomotor componentsMagnetic currentForce lines

The invention discloses a three-dimensional rotational flow magnetic gap magneto-rheological valve structure. The aims of lengthening an electromagnetic rheological fluid flowing path, improving the use rate of magnetic force lines, controlling the differential pressure of electromagnetic rheological fluid, saving energy and reducing the size of a magneto-rheological valve are achieved. According to the technical scheme, a valve element part in the structure comprises a center iron core, a spiral stopping ring and a sleeve, the center iron core, the spiral stopping ring and the sleeve are sequentially and concentrically installed in a sleeved mode to form a whole, a gap formed between the outer circle of the center iron core and the inner circle of the sleeve is divided by the spiral stopping ring into a spiral magneto-rheological liquid channel structure, a magnet exciting coil is arranged on the outer circle of the sleeve and arranged in a valve body, oil inlet-outlet discs are arranged on the end faces of the center iron core and the end faces of the sleeve, oil inlet-outlet holes in the oil inlet-outlet discs correspond to a spiral magneto-rheological liquid channel formed in the mode that the gap formed between the outer circle of the center iron core and the inner circle of the sleeve is divided by the spiral stopping ring, the valve body is installed in two valve body end covers, and oil holes in the valve body end covers are communicated with the oil holes in the oil inlet-outlet discs in the valve body. The three-dimensional rotational flow magnetic gap magneto-rheological valve structure has the advantages that the energy is saved, and the size of the magneto-rheological valve is small.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

A heat exchanger core for heat exchange of more than three fluids

ActiveCN106440892BRealize simultaneous heat exchangeImprove heat transfer efficiencyLaminated elementsStationary plate conduit assembliesEtchingEngineering

The invention provides a heat exchanger core for heat exchange of three or more fluids, and belongs to the technical field of heat exchange design. The heat exchanger core comprises n heat exchange plate groups and is formed by alternately stacking the n heat exchange plate groups which bear n heat exchange fluids; each heat exchange plate comprises a via hole heat exchange plate and a through hole heat exchange plate; each via hole heat exchange plate comprises a via hole matrix, two fluid via holes and a heat exchange flow channel machined on the via hole matrix through chemical etching; each through hole heat exchange plate comprises a cold plate and a hot plate, wherein the cold plate comprises a cold plate matrix, a fluid through hole and a heat exchange flowing channel machined on the cold plate matrix through chemical etching, and the hot plate comprises a hot plate matrix, a fluid through hole and a heat exchange flowing channel machined on the hot plate matrix through chemical etching; each heat exchange plate group comprises one or more cold plate or hot plates. The heat exchanger core for heat exchange of the three or more fluids has the advantages of being high in cooling efficiency and the like.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

Ice core remover and supercooled water ice machine

PendingCN108553972AReduce downtime failure rateReduce ice blockageLighting and heating apparatusIce productionSuper coolingWater ice

The invention relates to an ice-core remover and a supercooled water ice machine, and relates to the technical field of ice equipment and is designed to solve the problem of poor filtration efficiencyin the existing supercooled water ice machine. The ice-core remover comprises a cylindrical first shell, one end of the first shell is closed, and a water inlet and a filter outlet are arranged on the first shell, the first shell is internally provided with a rotating shaft, a partition plate and a rotary power device, the partition plate and the closed end of the first shell and the shell wall together form a closed filtering cavity, the rotating shaft is positioned in the filtering cavity, the rotating shaft is fixedly provided with a filter disc, the filter disc is in a spiral shape, and the edge of the filter disc is in contact with the inner wall of the first shell, the advancement direction of the filter is opposite to the direction of flow of the fluid in the first shell; the filter is capable of blocking the ice core in the fluid. The supercooled water ice machine includes the above-described ice-core remover. The invention provides an ice-core remover and an over-water ice-making machine, which are used for filtering the ice core and making ice by using the super-cooling method.

Owner:SHENZHEN VICLAND SHENGSHI ENERGY SAVING TECH CO LTD

Method and apparatus for circulating magnetic rheid non-linearly in magnetic gap space

InactiveCN1276192CIncrease the length of the runnerIncrease the differential pressureNon-rotating vibration suppressionFluid-pressure actuator componentsRheidMagnetic orientation

The invention relates to a process and apparatus for realizing non-rectilinear ring current in magnetic gap space for magnetic deformation fluid, wherein the magnetic gap space comprising a magnetic conductor and a magnetic insulator is provided with a magnetic insulation press ring, which insulates the magnetic gap space into the flow passage of the magnetic deformation non-rectilinear ring flow, the magnetic deformation flow enters the magnetic gap space from the entry port of the magnetic gap space, then extends along the ring flow defined by the magnetic gap space to the exit for outflow.

Owner:邱玲

Motor casing with layered long flow channels

InactiveCN102377278BIncrease the length of the runnerReduce noiseSupports/enclosures/casingsInlet channelEngineering

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Valve special for microsphere dispersion and suitable for diagnostic reagent

PendingCN108662167AIncrease the length of the runnerIncrease the itineraryLift valveEngineeringShear force

The invention relates to a valve special for microsphere dispersion and suitable for a diagnostic reagent. The valve comprises a valve seat assembly. The lower portion of the valve seat assembly is connected with a valve element assembly. The valve element assembly comprises a valve element body. The top of the valve element body is of a conic structure. A connecting ring is distributed on the valve element body. A conic containing cavity is formed in the valve seat assembly. The conic structure of the top of the valve element assembly is in contact with the conic containing cavity. The top ofthe connecting ring is in contact with the bottom of the valve seat assembly. The conic containing cavity is connected with a machining channel in a communicating manner. Thus, the top of the valve element body is of the conic structure, an impact ring is omitted, it can be guaranteed that impact force and shear force borne by microspheres during homogenization are within an acceptable range, andintegrity of the microspheres is guaranteed. Through mutual cooperation of the conic containing cavity and the machining channel, the length of a runner is increased, the dispersion stroke is increased, the work area is enlarged, and a good dispersion effect is achieved. The overall structure is simple, and assembling is easy.

Owner:安拓思纳米技术(苏州)有限公司

A helical blade counter-rotating double-runner water turbine

ActiveCN110397545BRelieve stress changesReduce the pressure gradientHydro energy generationReaction enginesHelical bladeWater turbine

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com