Low-noise motor casing structure with crossed flow channel of vacuum cleaner

A criss-cross, vacuuming motor technology, used in vacuum cleaners, cleaning equipment, household appliances, etc., can solve the problem of short air flow channels, and achieve the effects of increasing the length of the flow channel, low cost, and simple and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the drawings and examples. The same symbols are used for the same components in the present invention as in the prior art.

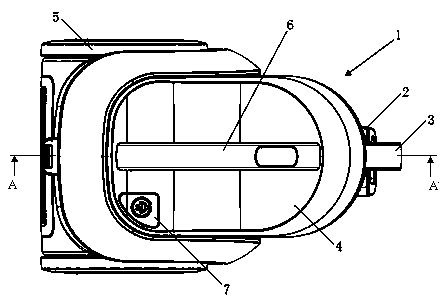

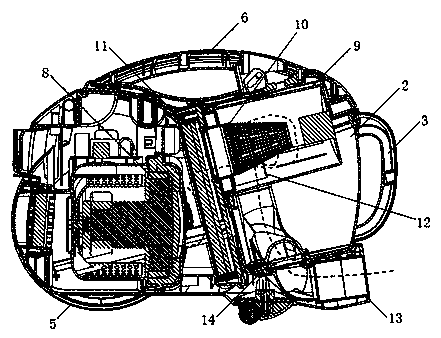

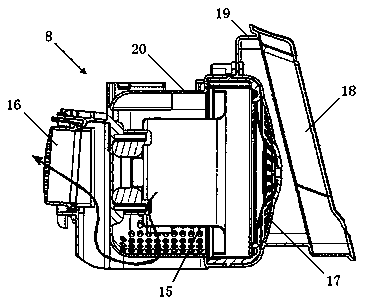

[0046] Figure 4 It is a three-dimensional structure diagram of the structure of the low-noise motor casing with cross flow passages of the present invention; Figure 5 It is a schematic diagram of the internal structure of the motor shell structure of the present invention. Such as Figure 4 with Figure 5 As shown, the low-noise motor housing structure of the cross-flow channel of the vacuum cleaner of the present invention is arranged in the body of the vacuum cleaner body. The vacuum cleaner body includes an upper cover arranged on the upper side of the vacuum cleaner body. An integrally formed handle for carrying the vacuum cleaner, and rotatable moving rollers respectively provided on both sides of the rear of the vacuum cleaner body to make the vacuum cleaner body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com