Pre-polycondensation reactor

A reactor and pre-condensation technology, applied in chemical/physical/physicochemical fixed reactors, etc., can solve the problems of short flow time, prolonging the total reaction time, polymerization reaction zone area, heating difficulties, etc., and achieve material flow time Prolonged, extended total reaction time, easy heating and stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

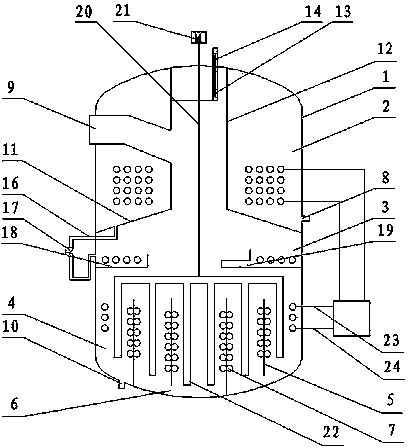

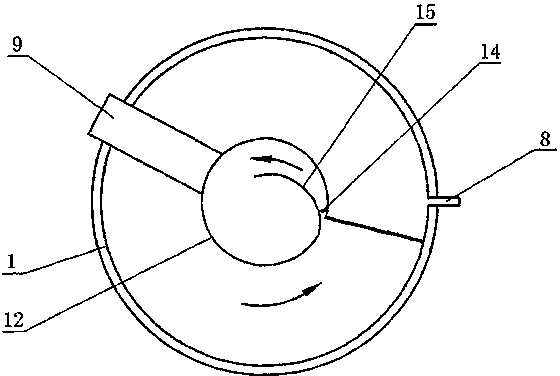

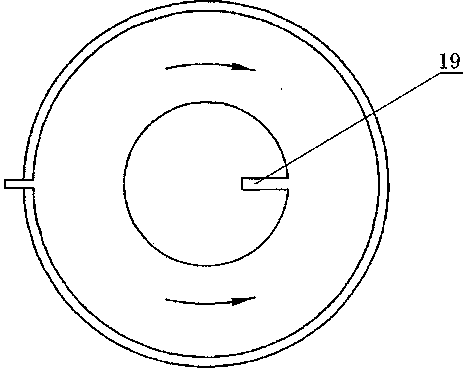

[0022] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a kind of precondensation reactor, comprises housing 1, and described housing is provided with upper and lower two-layer partition board, and described upper and lower two-layer partition board divides described housing into upper chamber 2, middle chamber Chamber 3 and lower chamber 4, the lower chamber is divided into a plurality of annular partitions by several annular partitions 5 arranged concentrically, the center line of several annular partitions arranged concentrically and the center of the housing The lines overlap, and the annular partition is provided with passage holes 6 communicating with the annular partitions on both sides thereof, and a heating coil 7 is provided in each annular partition.

[0023] The side wall of the upper chamber can be provided with a material inlet 8, which is communicated with the polyester esterification reactor through a pipeline, and the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com