Valve special for microsphere dispersion and suitable for diagnostic reagent

A technology for diagnostic reagents and special valves, applied in the field of special valves, can solve problems such as broken, microsphere deformation, and homogenization of microspheres that cannot diagnose reagents, and achieves the effects of increasing working area, simple overall structure, and good dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

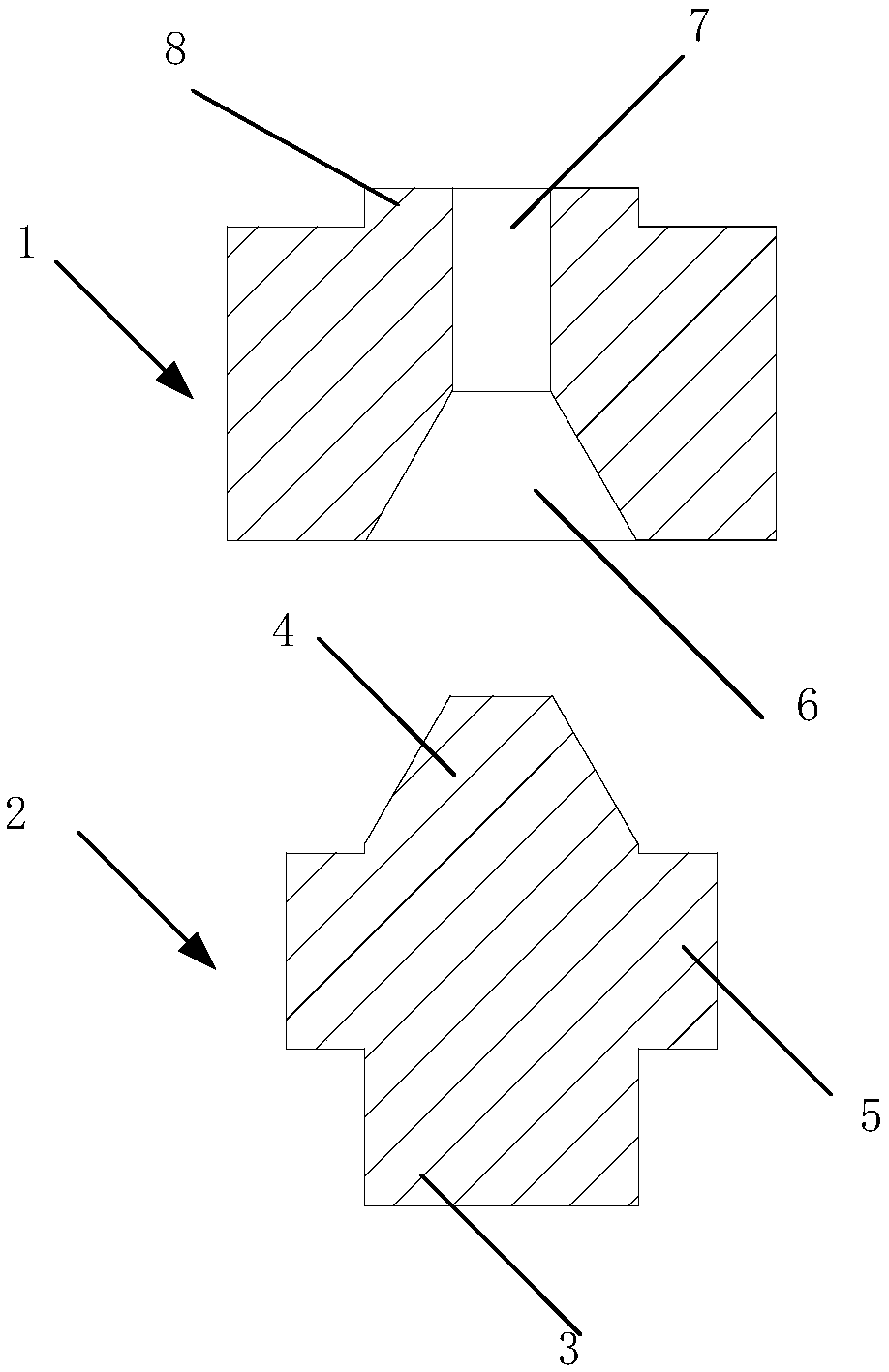

[0025] Such as figure 1 A special valve for microsphere dispersion suitable for diagnostic reagents, including a valve seat assembly 1, a valve core assembly 2 is connected below the valve seat assembly 1, and its difference lies in that: in order to form a flow-limiting slit, it does not need Adopting a traditional impact ring structure, the valve core assembly 2 includes a valve core body 3 , and the top of the valve core body 3 is a conical structure 4 . In this way, the impact force and shear force can be reduced to an acceptable level during actual use. In other words, with such a configuration, the shearing force between the valve seat and the valve plug can be alm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com