Spiral-blade opposite-rotation type double-runner water turbine

A technology of double runners and helical blades, which is applied in the field of helical blade counter-rotating double-runner water turbines, to achieve the effects of improving efficiency, reducing pressure gradients, and lowering the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The practical relationship will be further described below in conjunction with the accompanying drawings and specific embodiments.

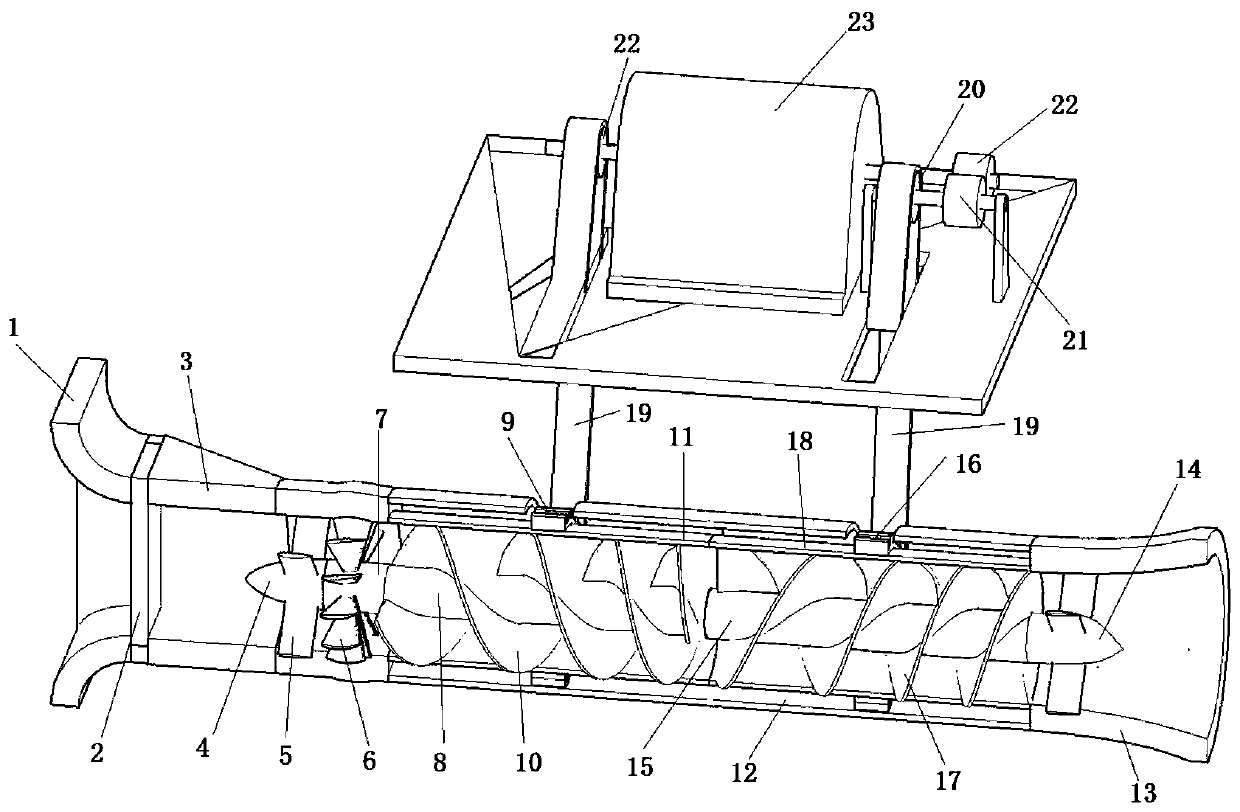

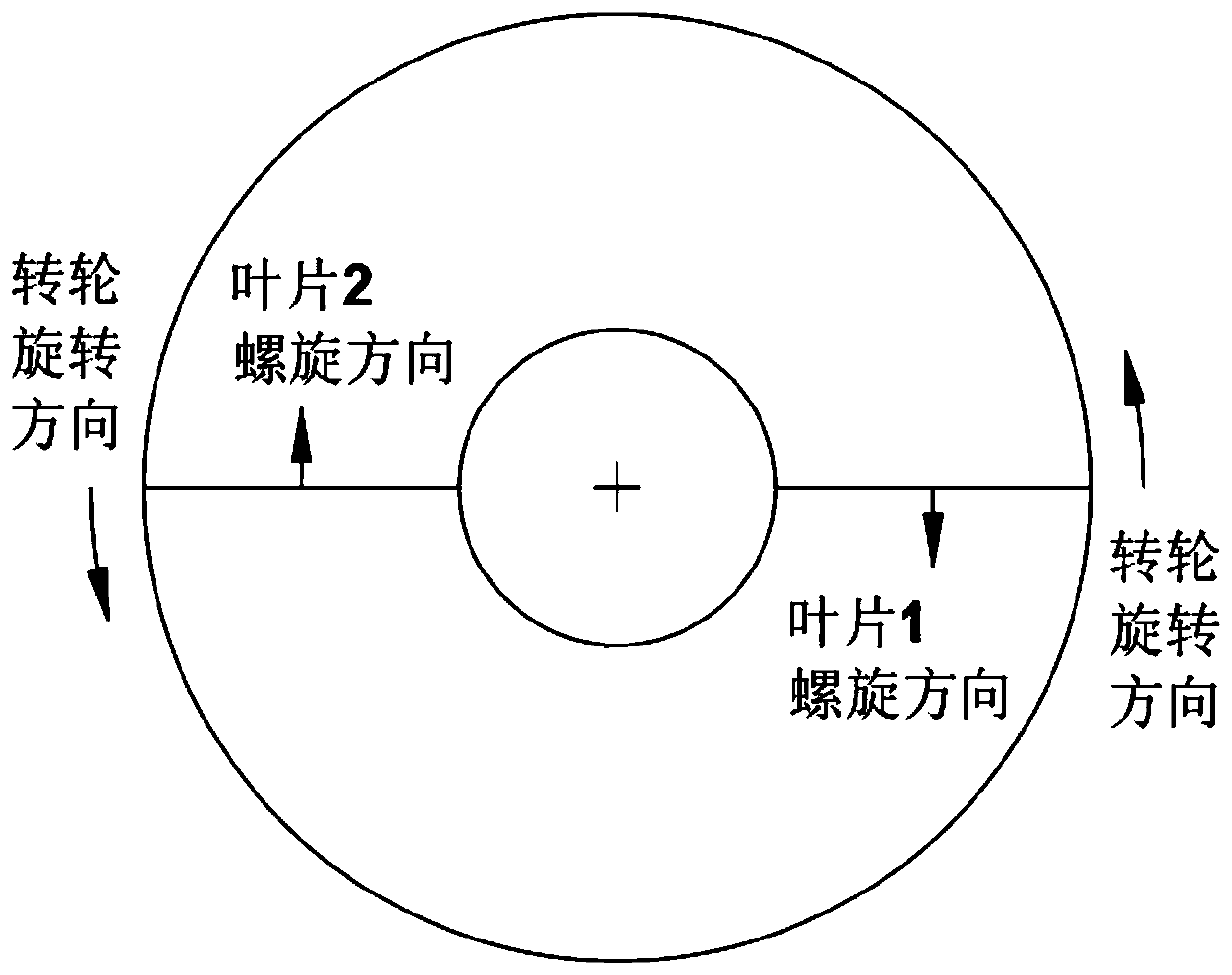

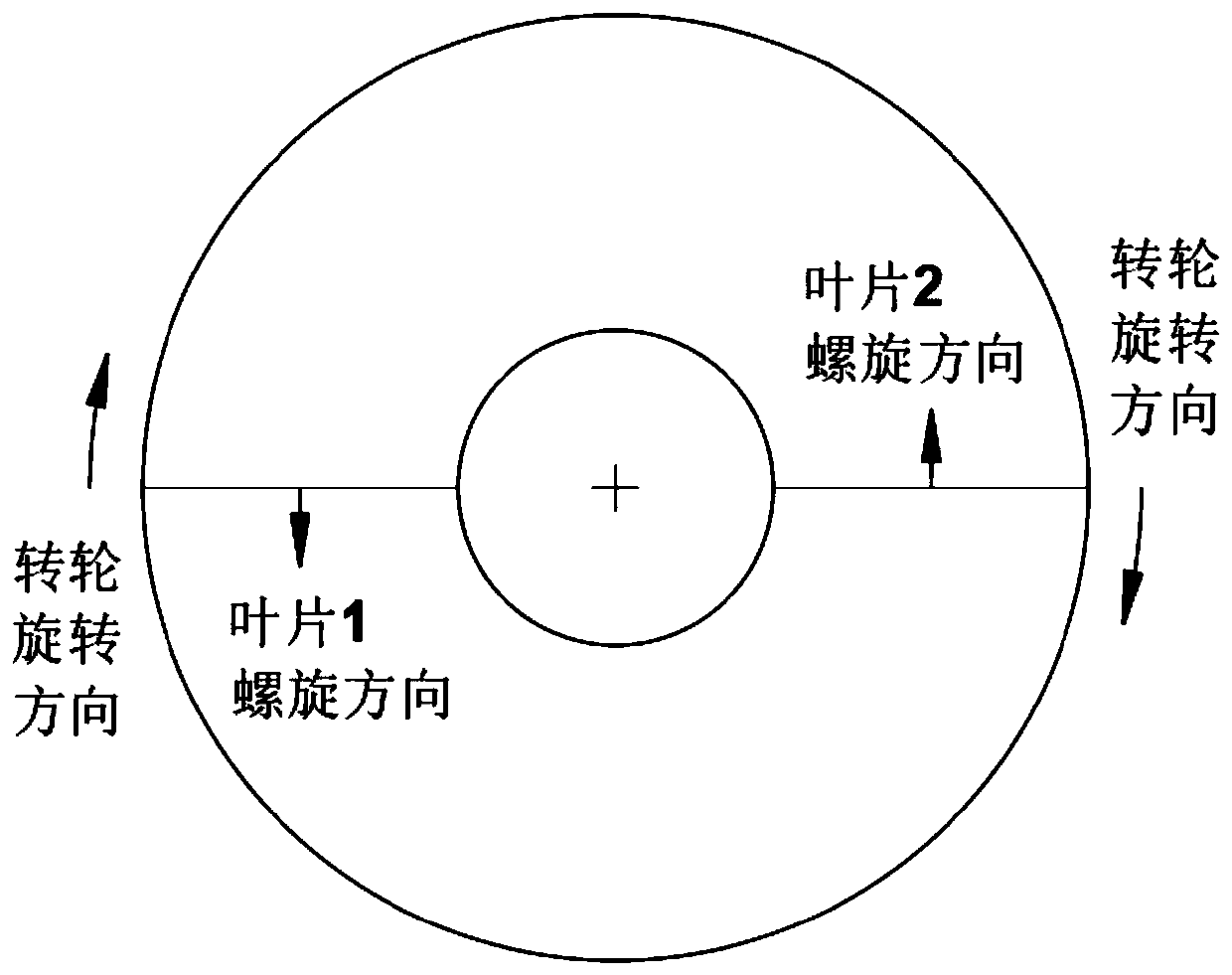

[0034] Such as figure 1 , 2 As shown in , 3, a helical vane counter-rotating double-runner water turbine includes a diffusion section 1, the opening of which is a square structure, and its main body is a truncated cone structure. The diffuser section 1 is connected with a square-circle gradient section 3 behind it, and the square-circle gradient section 3 transforms the square structure of the front diffuser section 1 into a rear circular structure. A casing 12 is connected to the radius-changing section 3, and the casing 12 is a cylindrical structure. A tailwater section 14 is connected with the shell 12, and the tailwater section 14 is in the shape of a truncated cone. A front runner and a rear runner are arranged inside the housing 12 , and the front runner and the rear runner rotate in the housing 12 respectively.

[0035] The fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com